What are the factors of choosing a heat exchanger?

The material with which a plate corrugated stainless steel printed circuit heat exchangers is built is one of the determining factors both for its construction and for its possible choice.

In particular, very careful considerations regarding the choice of material must be made if the use of the exchanger has to do with a pressure that rises above 70 bar and with a temperature above 550 ° C.

Furthermore, the choice of an exchanger also influences by other factors that we are only going to list. They are:

- the tightness (when working with toxic or even precious and expensive fluids);

- ease of use;

- low maintenance costs;

- the security;

Plate Corrugated Stainless Steel Printed Circuit Heat Exchangers

Heat exchangers are equipment that allows the efficient transfer of heat from one medium to another. They are normally common in air conditioning, refrigeration, power plants, water treatment systems and chemical plants.

Where is it common?

The Searchable Plate Heat Exchanger is a revolutionary device. It has greatly improved manufacturing and industrial processes in many companies. Many of the largest companies are investing heavily in this technology, as it can help reduce costs and thus improve corporate business growth.

Here are some of the advantages of temperature exchangers

Adaptability and versatility

Modern plate corrugated stainless steel printed circuit heat exchangers are adaptable and versatile. They can be common to perform a wide variety of tasks. Additionally, the newer models are available in compact sizes which make them portable and lightweight.

These heating devices are designed according to the needs of the consumer. It is possible to modify them according to the requirements of the individual project.

Better management of Temperature

These devices are able to better manage the temperature levels to maintain. In particular, the counter-current models are the ones that offer the greatest control over the temperatures of the fluids.

Furthermore, their excellent resistance to wear and to high temperatures makes plate corrugated stainless steel printed circuit heat exchangers ideal also for continuous applications.

Price Becoming More And More Affordable

With the advancement of technology and their diffusion, the price of heat exchangers is becoming more and more affordable. The market is extremely competitive, therefore there will be a continuous improvement of the exchangers and a subsequent reduction in the price of the models.

Do Not Require A Lot of Maintenance

Energy efficient heat exchangers do not require a lot of maintenance. They do not corrode easily and can function for many years. The replacement of the various pieces is very simple, and if you are familiar with DIY you can carry out the maintenance yourself without many problems.

No Combustion and The Harmful Products

This plate corrugated stainless steel printed circuit heat exchangers are safe to use. Inside there is no combustion and the harmful products that are formed during the various processes are eliminated immediately. Their use produces a reduced quantity of pollutants when compared with traditional heating methods.

As we have seen, heat exchangers are an excellent way to increase the efficiency of heating and refrigeration systems. Their use, both in the domestic and industrial fields, now sees them common in the most different situations.

If designed in the best way, in addition to optimizing the entire refrigeration and / or heating process, they also make plate corrugated stainless steel printed circuit heat exchangers possible to significantly reduce the amount of pollutants that are released into the atmosphere.

Widely Common in The Industrial and Civil Sectors

Heat exchangers are devices widely common in the industrial and civil sectors. From the chemical sector to environmental air conditioning, they allow the transfer of heat from a hot fluid to a cold one without these coming into contact. Increasingly high energy efficiency requirements call for the optimization of these devices.

Consequently, once the type of exchanger has been chosen, during the sizing phase we find ourselves having to face an optimization problem with innumerable degrees of freedom.

For example, if you choose to install a finned tube and cross flow exchanger, you need to determine the material and size of the tubes and fins. The number of tubes, ranks, fins and the distance between them in plate corrugated stainless steel printed circuit heat exchangers are also important. The only constraints are on flow rates, outgoing temperatures and footprint.

Correlations That Help the Designer

In cases of standard conditions, there are correlations that help the designer. However, in the vast majority of cases, working conditions are particular and correlations offer poor results. Precisely in these cases, we can make a great contribution with CFD analyzes and direct the customer towards the most efficient and economical solution.

An Example from CFD Analysis

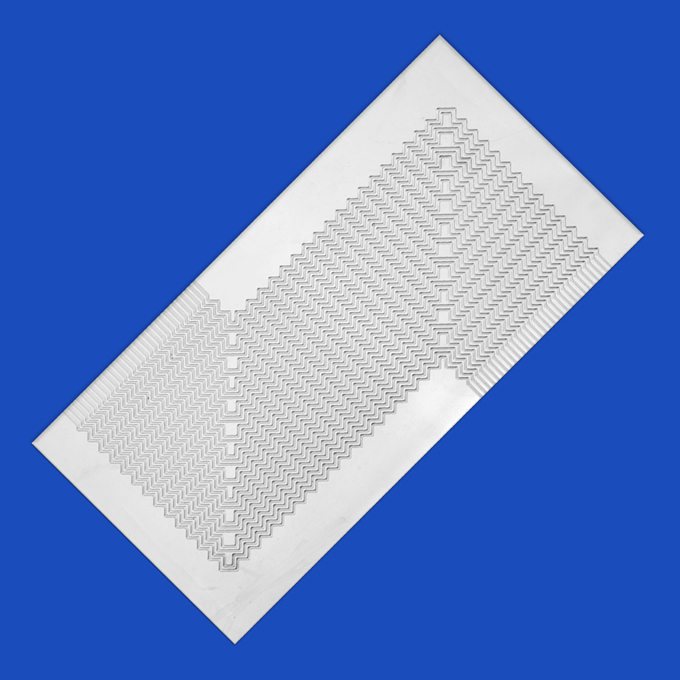

An example of a plate corrugated stainless steel printed circuit heat exchangers on a cross flow tube exchanger is here. Inside the pipes hot water flows while outside the pipes lap by cold air. From the image it is possible to observe the increase in temperature of the air that laps the pipes inside which the hot water flows, which at the same time cools down.

The Fins Increase Heat Exchange

The implementation of the fins allows to increase the exchange surface and, therefore, the heat exchanged. In the following image it is possible to appreciate the CFD analysis of the same exchanger shown above but finned.

The fins increase the plate corrugated stainless steel printed circuit heat exchangers: the air reaches a higher temperature while the water reaches a lower temperature.

Heat exchangers are also common to evaporate a liquid stream or condense a gaseous stream. These phenomena are complex. Moreover, they include the change of phase and, therefore, of the properties of the fluid under analysis.

The phase changes from water to steam. Similarly, it takes place inside a pipe heated by a warmer external fluid is shown below.

Bypass Regulation in Plate Corrugated Stainless Steel Printed Circuit Heat Exchangers

In this case the exchanger operates at a constant flow rate and the inlet temperature varies. This is possible because a branch comes downstream of the exchanger which recirculates part of the outgoing flow to a three-way mixing valve located upstream.

This valve mixes two inlet flows. It is to obtain an outlet flow whose flow rate remains constant. Similarly, the temperature varies according to the amount of fluid recirculated in the branch.