Micro Channel Flow Plate for Improved Energy Solution

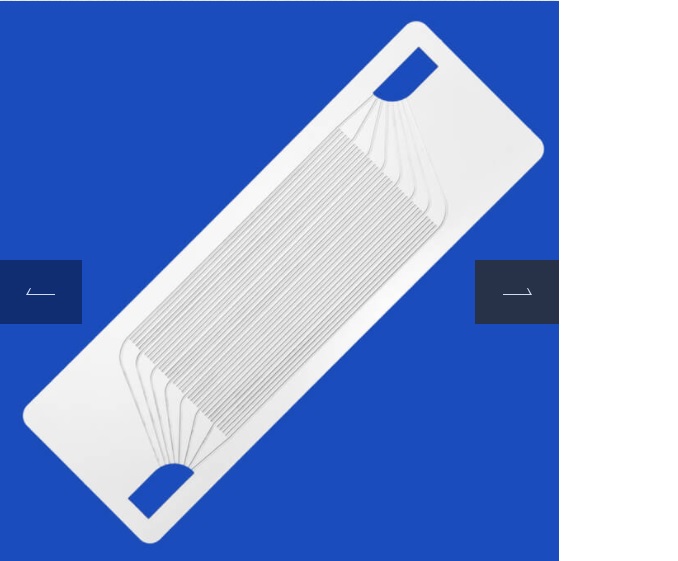

Micro channel flow plate heat exchangers were developed to efficiently manage the heating system. The next-generation micro channel plate was a revolutionary technology in energy efficiency. The features of metal plates used in the heat exchangers allowed the flow of two liquids and heat transfer between the two fluids. Today, the plates’ unique pattern outclasses everything in the category of micro channel heat exchangers (MCHEs). The usually stainless steel or aluminum flow plate has a fundamental role in micro fluid applications and biomedical devices. A number of such flow plates stack together through diffusion bonding inside MCHEs for distinct energy solutions. The flat metal plates machined with channels let the fluids flow.

These plates are suitable for virtually every situation with varying temperatures and pressure. They adapt to tailored heat exchangers for maximum heat transfer between two fluids. The plate’s high efficiency and longer lifespan optimally allow water to flow, resulting in a lower carbon footprint. The plates are available in varying sizes, and width gaps depending upon the requirement of micro channel heat exchangers.

Long Service Life with Micro Channel Flow Plate

Microfluidic technology has always been crucial in the advancement of flow sensors and heat sinks for chip cooling. The plate offers long service life due to free flow channels. The parallel-width gap cross-section between the individual plates and rough-wave profiling of the plats is usually is usually 12 mm. Due to constant width-gaps, the free flow channels carry on the operation without clogging. The high-quality, durable flow plats with superior steel finish are corrosion resistant. Their material adheres to set industry standards. Fabrication of micro channel plates increases the life of microfluidic devices. They are highly flexible parts for heating, cooling, and heat recovery in MCHEs.

MCP plate heat exchanger fundamentally performs on the main cooling machine. The integrated corrugated metal plate contains four corner holes to guide eh liquid to flow for heat transfer. The structure of micro channel plates varies according to the use of applications.

Design of Micro Channel Flow Plate

The maximum plate size to produce each exchanger core ‘block’ is 600 x 1500mm. If needed, the final exchanger core may contain multiple blocks joined together through diffusion bonding. Each individual design and corresponding exchanger is tailored. Qualified mechanical and chemical engineers create the design to match duty specifications. Some hot and cold flow plate designs depicting counter flow, multi-pass counter-cross-flow, and multi pass counter-flow are:

Etching

Stollpche’s technology etches complex flow plates on both sides with exceptional accuracy. The etching process comprises the following steps:

- opening and cleaning of the plate

- coating and drying

- exposure and development

- drying, etching, and release

- detection and packaging

- finished product

Manufacturing Techniques

Previously a single technique involved in creation of the flow plates. The recent update to this technology integrates a thin-film deposition method with glass-capillary array substrates. This combination is important to gain secondary emissive and resistive micro channel plate properties. There are various advantages in this approach. The two manufacturing techniques are:

Conventional Method

The traditional process fills lead-glass tubes (pipes) with glass rods. Rod and rube assemblies thermally co-draw to cause the tube (pipe) collapse near the rod to create slender fibers with lead-glass covering and the inside core glass. The parallel-stacked fibers stretch together to form multiple assemblies. Then, core glass etching takes place to produce several pores, measuring a diameter of 10 to 20 µm. The lead-glass array exposes to heat under hydrogen presence to lessen the glass surface chemically. Finally, an emissive and resistive surface emerges suitable for electron amplification.

Atomic Layer Deposition Manufacturing

This new compact micro channel flow plate manufacturing technique starts with capillary tubes drawn from the borosilicate glass. There is no need to cut away the core as they are hollow fibers. As a result, cost lowers and eliminates the upper limit, especially on the diameter’s ratio length. The sliced bundles of the fused capillary create flat adjacent pores plates called glass capillary arrays (GCA). The block slicing occurs with long capillaries’ parallel fusing into the water for final polishing. Micro channels take the hexagonal form and get vivid in open area ratio, reedy wall capillaries. Lenses and X-Ray concentrators are two examples of a hollow-drawn capillary application. ALD coated microchannel flow plates have better strength and they do not require hydrogen firing.

Conversion of Glass Capillary Array (GCA) into Micro Channel Plate (MCP)

GCA transforms into MCP by including the thin film to instill the required plate resistance. Later, another thin film adds to form a subordinate emission layer. Atomic Layer Deposition (ALD) ALD method adds the vital thin film to let the micro channel plate application decide about the required resistance. Higher resistance leads to a low-power operation useful for portable instruments or spaceflight.

The lightweight microchannel plates comprise glass with 60% or even more proportion of the open area. Usually, their thickness lies between 0.02mm to 2.0mm. Aerospace, military, and nuclear industries require highly reliable parts. This is possible by producing complex parts with flow plate-based diffusion bonding. Stainless steel, aluminum, glass, nickel superalloys, and ceramic are other materials demanded by such industries. Diffusion bonding with flow plates also uses dissimilar metals for joining such as steel/copper and Titanium and Iron-Nickle alloys.

Summary

The unique design of the flow channels in a micro channel flow plate achieves the desired liquid flow and heat transfer. The suppliers of cooling and heating systems use these plates in vacuum diffusion bonding technology. The burr-free, stress-free, and flat, chemically etched heat exchanger plates reduce energy cost and increase work efficiency. Microchannel plates comprise glass with 60%, or even more proportion of open area ensuring less weight. Usually, the thickness of the plates is between 0.5mm to 1.5mm. The lightweight plates are also used as space flight instruments.