Are There Any Benefits Of a Heat Exchanger?

Heat exchangers come in a variety of sizes and shapes. What’s more, you can utilize all the types of heat exchangers in a variety of innovative techniques depending on the needs of the application. Thus, there are undoubtedly many benefits of heat exchanger for businesses. Want to know more about their benefits? Keep reading then. You will find everything you need to know below.

What Is A Heat Exchanger?

To put it in simple words, the heat exchanger is a device that transfers heat from one source to another. A great example of a heat exchanger is a hydraulic oil cooler. It works by removing heat from oil with the help of cold water or air.

Other than that, there are swimming pool heat exchangers available in the market as well. It uses hot water from a solar-heated water circuit or hot water from the boiler to heat the water in the pool. Heat is transferred to the water with the help of conduction and the exchanger materials. These exchanger materials separate the medium that you use in heating up the liquid.

Another common type of heat exchanger is the shell and tube, heat exchanger. These devices pass the fluids through the tube where air-cooled heat exchanger passes the cool air through the core of fins to cool down the liquid.

Different Types of Heat Exchangers Out There

There are many different types of heat exchangers available in the market and there are different benefits of heat exchanger according to their types. Let’s take a look at some of the common types below.

1. Shell & Tube Heat Exchanger

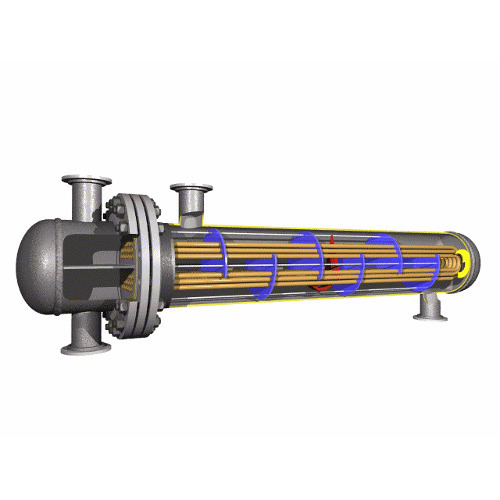

One of the most common types of heat exchangers is the shell & tube heat exchanger. It consists of a large number of tubes that are extremely small in size. These small tubes are located within the cylindrical shell and positioned in such a way that they go directly into the cylinder using a tube stack or a tube bundle. These tube stacks or tube bundles either have fixed tube plates or expanding and contracting tube plates. The manufacturers fix the tube plates permanently into the body. However, you can easily remove the expanding and contracting tube plates for services and maintenance.

2. Plate Type Heat Exchanger

The plate-type heat exchanger is another common type of heat exchanger that people all over the world use. They operate similarly to the shell & tube heat exchanger. However, they use a series of stacked plates instead of tubes. In addition to this, they are gasketed or brazed as well. But, the gasketing or brazing depends upon the fluids and applications that they use. One of the major benefits of heat exchanger using plate type is that it is made up of compact stainless steel. This is what makes it an ideal choice to use in food and beverage processing.

3. Air Cooled Heat Exchanger

The air-cooled heat exchangers are extremely common in mobile applications or vehicles. That’s because these machines do not have any permanent cool water source available. This is what makes the air-cooled heat exchanger a perfect choice for them. The machines get the cool air with the help of a fan or airflow. This helps in causing the movement of the vehicle as well.

What Are the Benefits of Heat Exchanger in Processes and Clean-Up Places?

There are many benefits of heat exchanger in processes and clean-up places. Let’s take a look at some of these benefits below.

1. Smaller Footprint

One of the major benefits of heat exchanger is that they offer a smaller footprint. The advancement of modern technology makes these devices more powerful but smaller and versatile as well. As a result of the shrinking space, the footprint becomes smaller as well. This is what makes these devices extremely efficient to use.

2. Lower Environmental Impact

Apart from the smaller footprint, the heat exchangers offer lower environmental impact in the processes as well. That’s because these machines run continuously to ensure that control panels that are of extremely high power don’t heat up. This is due to the fact that these machines do not require complicated external equipment to run properly. Since they use significantly less energy and produce no pollution as compared to the other conventional cooling methods, they leave a lower impact on the environment as well.

3. Minimal Operating Cost

Another one of the great benefits of heat exchanger that it needs minimum operating cost to run. That’s because they do not use any complicated external equipment. Not only this but they eliminate the majority of the contamination. These devices also don’t break down easily and can last for a longer time as compared to the other air conditioning units. That’s why the need to replace them reduces.

4. Saves Energy

Sanitization depends on the heat exchanger's capacity to recuperate heat from handled milk. For purification, milk must be put away at 4°C to forestall microbial development. During purification, milk is warmed to a temperature of 72 °C for no less than 15 seconds to kill microbes and afterward chilled back to 4 °C to stop the cycle and protect the milk. The heat of the sanitized milk is utilized to warm the virus milk. The approaching virus milk is preheated by the active hot milk, which is all the while pre-cooled. This exchange productivity saves warming and refrigeration energy.

5. Creates Consistent Temperature

Heat exchangers play an effective role in creating consistent temperature for the food and beverage industry as well. In addition to this, they help in cleaning the fluids from the system components as well. This is what makes it the top choice of the people.

Final Words

There are many benefits of heat exchanger for normal people and for businesses as well. For this reason, they are becoming the top choice of everyone. Need more information on the heat exchangers? Contact us now!