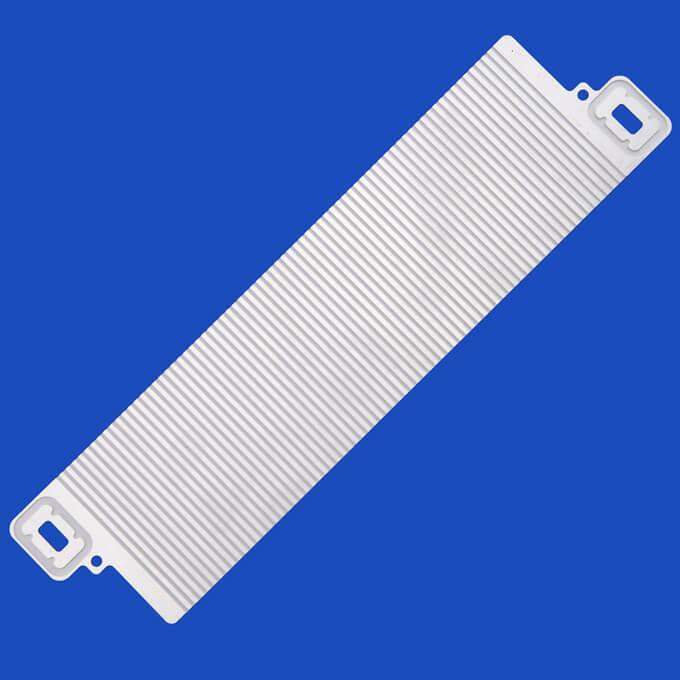

Introduction of the Compact micro channel perforated flow plate

The Compact micro channel perforated flow plate is very easy to operate, since the human influence is minimal. It is enough to connect the equipment and complete the process. The downside is that it is difficult to select a reagent. Also, it is not every chemical composition is able to cope with the removal of the contaminant.

Cons of the Compact micro channel perforated flow plate

Perennial deposits cannot remove by a CIP method;

The complexity of the selection of a chemical reagent in accordance with the intended purpose of the operation of the heating unit;

The mechanical method is less dangerous and does not pollute the environment. The disadvantages include the procedure for disassembling the flow plates and possible mechanical damage to some parts, which leads to the need to replace the element. This increases the cost of the job. Similarly, the cons include:

Complete disassembly of the unit is compulsory

- is present in 95% of manual labor;

- Also, possible damage to the elements of the heating unit;

- Furthermore, it is necessary to select the correct locksmith tools and accessories for the mechanical effect of removing the contaminant.

- Moreover, the combine method is the most effective, since you can achieve 100% of the work result. The disadvantages include the need to disassemble systems and assemblies, and the high cost of work.

Flow plates cleaning methods

Flow plates cleaning methods

It is recommended to clean the heating circuit in the boiler system once every 3 years. But if hot water supply is loaded in the circuit, then cleaning is recommended at least once every 6 months.

The regulating automatics will tell you about the deterioration of the system and help determine when it is necessary to do at least a listed flushing.

If there is a malfunction of the automation, and not because of the failure of their electronic components, the Compact micro channel perforated flow plate must be flushed immediately. Otherwise there is a risk of complete failure of the equipment.

Water does not have its own clear parameters, and if hardness softeners are not common, then scale can form very quickly. If the system is easy to supply with different water hardness, flushing of the circuits is necessary every 3 months.

Factors have been identified flow plates is needed:

- the pressure in the system drop sharply;

- there are signs of a sharp increase in thermal energy;

- temperature regimes have unstable indicators,

- moreover, for a certain period,

- that is, in the range from 1 to 15 minutes,

- with a stably set system of flow plates operation.

The quality of the Compact micro channel perforated flow plate operation will largely depend on which cleaning option you use for these purposes.

Choice of the method of the cleaning

Entrust the choice of the method of cleaning the flow plates to specialists and get stable operation of the heating equipment in the future.

A pool flow plates is a special heat and power device. Moreover, it heats the water in the pool. The flow plates provide cyclic heating of the liquid (just drawn into the pool bowl from the water supply system) to the required temperature.

Furthermore, it maintains the definite temperature regime, thus replenishing the heat loss produced by the evaporation of water and its contact with the tank walls.

Recuperative pool flow plates:

- does not consume excess electricity;

- has a simple design;

- Moreover, easily connects to the pool water treatment system and central heating pipelines;

- has a high heat exchange efficiency

- Schematic diagram of heat exchange between Compact micro channel perforated flow platecircuits

Design of the Compact micro channel perforated flow plate

The design of any flow plates for the pool is a double-circuit flow-through tank. Through a system of pipelines, the outlet pipes of one circuit are connected to the city central heating collector, from which hot water is full - the heat carrier. The second circuit is connected to the pool reservoir - the consumer.

Flow plates do not generate heat energy on their own, but through the easy to form heat exchange surface (the surface of plates or tubes) act as intermediaries in its transfer.

Installation of the Compact micro channel perforated flow plate

The compact micro channel perforated flow plate for the pool is an integral unit of the general water treatment system common at the hydraulic structure. Install it after the circulation pumps and filter elements - in front of the chemical reagent dispensers.

The flow plate is easy to mount at the lowest horizontal mark - below filters, pipelines, air vent, to exclude the possibility of atmospheric air entering the hydraulic circuits. The connection of the circuits of the heat exchange device to the pipelines of the coolant.

And the heated water is easy to carry out through shut-off valves, which allow dismantling the equipment for technological maintenance without violating the tightness of the connected pipelines.

How to control temperature with sensor?

The solenoid of the control valve is connected to the thermostat head of the temperature sensor fit on the outlet pipe of the heated liquid circuit. Also, the thermostat head, set to a certain temperature range, gives signals to open / close the control valve for the heating medium supply.

The coolant and heated water move along the contours form by the package of metal plates. Rubber seals, fixed on the working surface of the plates, prevent the leakage of circulating liquids. However, each plate is easy to wash on one side with a hot coolant.

It is also, on the other - with cool water coming from the pool. A metal partition with a thickness of 0.5-0.6 mm does not interfere with the transfer of thermal energy from a heated liquid to a cold one. Fluid streams moving with high turbulent velocity clean the channels of the plates from fine mechanical debris.

Benefits of Compact micro channel perforated flow plate

- heat exchange efficiency 90-95%;

- Also, small size and weight;

- Moreover, low heat carrier consumption;

- Furthermore, the ability to connect all pipelines on one side;

- In addition, the ability to regulate the thermal power of the Compact micro channel perforated flow plateby changing the number of plates in the package;

- Also, simple operational maintenance;

- Moreover, replacement of the failed heat exchange plates by a regular plumbing team.

Conclusion

If the flow plates and the pool is easy to locate at a considerable distance from the central heating unit, then an additional circulation pump is cut into the pipeline branch transporting the cool heat carrier. The smooth operation of the pumping equipment ensure by the creation of a bypass.

This allows transporting the hot cool in parallel with the control valve and the flow plates.