INTRODUCTION

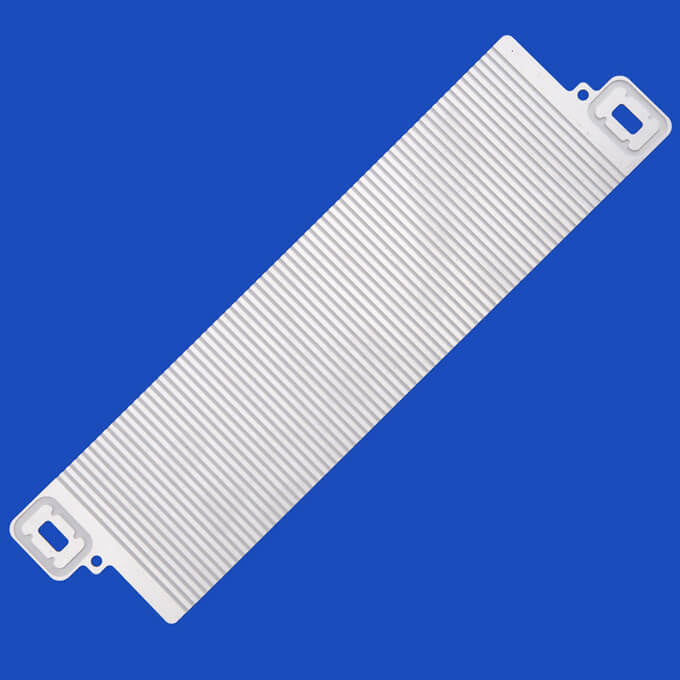

Disassembling and assembling the compact perforated micro-fluid channel plate is part of the regular maintenance of this type of device, which was discussed in the previous article.

Table of Content

- How to disassemble a plate heat exchanger

- How to properly assemble a plate heat exchanger

- System startup

- Conclusion

During the operation of the compact perforated micro-fluid channel plate unit, deposits, scale, rust and other contaminants accumulate on its internal surfaces, which lead to a decrease in the efficiency of heat transfer from one medium to another. To clean the heat exchanger, it is necessary to disassemble it, flush it and then reassemble it.

If regular maintenance was carried out at the wrong time, as well as a result of extreme loads, leaks of seals and deformation of the plates are possible, which will require their replacement and, as a result, disassembly of the unit to access the damaged elements.

HOW TO DISASSEMBLE A PLATE HEAT EXCHANGER?

The disassembly procedure for the compact perforated micro-fluid channel plate is as follows:

It is necessary to stock up on a pair of friction wrenches of a suitable diameter for the corresponding size of the tightening bolts (so for the heat exchanger it is the 24th diameter), in cases of disassembling large units, this can be a pneumatic tool.

Protective gloves are common to avoid cutting your hands on the edges of the plates.

The supply pipelines are drained and turned off. In this case, it is desirable to maintain the visible distance between the pipes and the heat exchanger body.

In order to assemble the bag in the correct order after service, each plate is numbered with a permanent marker. Alternative: before disassembly, a marker is drawn along the edges of the working plates (diagonally).

Compact perforated micro-fluid channel plate marking during disassembly

Alternative marking option

If the device is new, the factory seal is cut off with pliers, and the protective insulation removes from the pins.

The size of the screed of the plate package measures (needed for reassembly).

To avoid damage to the threads on the studs and tie bolts, before disassembling, grease their surface with "graphite" or treat with WD-40 liquid.

If there are 4 tie rods in compact perforated micro-fluid channel plate, then the tie nuts loosen diagonally by 1-2 turns. If there are more of them, for example, 6, then first weaken the central ones, and only then move on to the corner ones.

How to loosen the tie bolts when disassembling the plate heat exchanger?

How to loosen the tie bolts?

- The coupling nuts completely unscrew and remove together with the studs

- The movable plate pushes as far as it will go to gain access to the plates

- The plates are alternately moved apart (first, their lower edges retract) and remove from the frame

- Dismantling the plate heat exchanger: removing the plates

- The bottom edge of the plate shift first.

Important: metal plates are sometimes exposed to extreme temperatures, after which it can be difficult to separate them. It is necessary to act very carefully so as not to break the seals.

HOW TO PROPERLY ASSEMBLE A PLATE HEAT EXCHANGER?

After carrying out maintenance - flushing the compact perforated micro-fluid channel plate or replacing non-working elements, the assembly process takes place in the reverse order:

The side plates extend all the way

The first plate installs on the frame and slides towards the fixed plate. Similarly, the spacers must face this plate. Based on the markers made during the disassembly process, the remaining plates assemble and install in the correct order.

How does compact perforated micro-fluid channel plate work?

Moreover, the pressure plate moves as close as possible to the plate pack. The studs install, in cases where their damage finds, the faulty studs and tie bolts must replace.

All nuts tighten one turn, after which it is necessary to ensure that the seals are level. Next, the nuts tighten in a diagonal order, alternately turning them 1-2 turns. The compact perforated micro-fluid channel plate assembly process is good in its own direction:

How to fix pressure compact perforated micro-fluid channel plate?

Important: in order for the plate pack to sit evenly, after the screed, the pressure plate must be parallel to the fixed plate. It is necessary to tighten the package so that the top of the pressure plate is ahead of the lower edge by a maximum of 1-2 cm.

The screed size approaches the maximum allowable value (which was measured earlier), the edge lead should reduce.

SYSTEM STARTUP

In reverse order, the inlets and outlets of the compact perforated micro-fluid channel plate connect to the piping. During installation, it is important to bleed air from the internal circuit of the unit before supplying heat transfer fluids.

During the maintenance process, the seals replace with new ones. The supply begins with a cold coolant in order to avoid damage to the gaskets. Furthermore, the seals have not changed, and then the supply begins with a hot coolant in order to restore the working characteristics of the gaskets for proper heat transfer.

Why should you monitor fluid channel plate?

During the start-up process, it is mandatory to monitor the pressure and temperatures at the inlet and outlet of the heat exchanger.

In the energy, petrochemical and oil/gas industries, many types of heat exchangers are being common. The heat exchanger is common to heat and cool down the condensate flow of the steam unit.

Depending on the application, heat exchangers come in all shapes, sizes and materials. The most widely common models are tube/shell exchangers and fin coolers (tube/shell exchangers and fin/fan coolers)

CONCLUSION

In this article, we tried to describe in as much detail as possible how the process of disassembling and assembling compact perforated micro-fluid channel plate takes place. If you have any questions, please write or call us. In the next article, we will consider the use of plate heat exchangers in heating systems - subscribe to the news!