Compact platelet heat exchangers are famous as a device for storing and heating hot water. Such equipment’s are also capable of storing ice water and maintaining its temperature. This option will reduce resource consumption where various refrigeration units are installed.

What materials common in compact platelet heat exchangers?

The configuration of compact platelet heat exchangers is approximately the same. It is a barrel-like, cylindrical shape that is easy to mount both vertically and horizontally. The tank is made of steel, aluminum or alloys, and its inner lining is easy to make:

- Firstly, Enamels - suitable for storing sanitary liquids

- Also, Insulating protection against condensation

- Additionally, galvanized steel - common in devices for heating and service water

- Lastly, stainless steel - suitable for storing household water (drinking)

Depending on the model and accessory of the compact platelet heat exchangers to a particular manufacturer, it is easy to supply with an internal epoxy coating (anti-corrosion system). With a reinforced coil that allows you to heat more water in less time, with a high operating temperature range (up to 150 degrees)

Overview of equipment and technical characteristics

The convenience of using this indirect heating heat exchangers in domestic, commercial, and industrial areas is explained by the variability of a wide range of models. For example, the volume varies from 80 to 10 thousand liters.

Also, with other main characteristics of equipment, its designs involve the use of steam and liquid heat carriers. Use of insulation in compact platelet heat exchangers to reduce heat loss. The ability to mount the device in a horizontal and vertical position, as well as the maximum temperature regime.

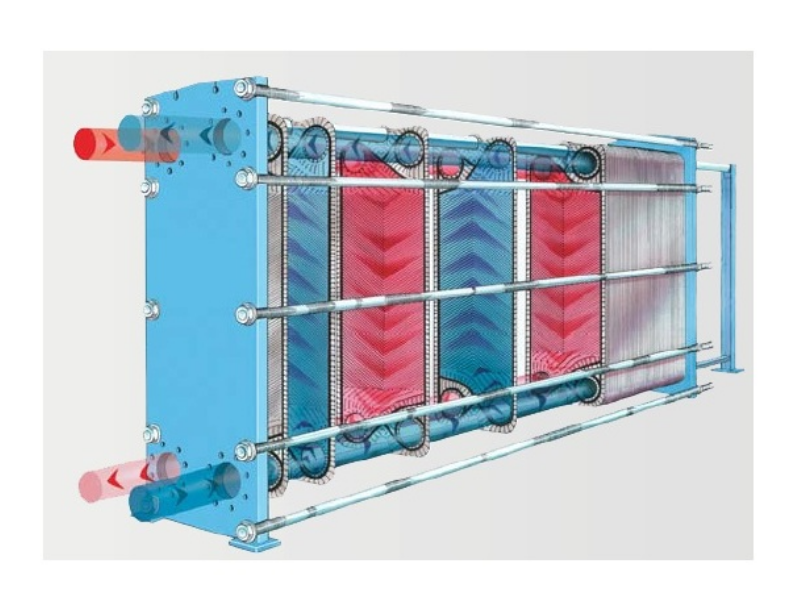

Construction of heat exchanger

Due to the different operating pressure (from 6 to 16 bar)- the devices is easy to install in autonomous or central highways. The main equipment is a copper or stainless steel pipeline, which is located in the inner space of the tank. It is through the tube that the functional fluid passes.

This means cooling or heating the steam-water inside the compact platelet heat exchangers by a contact method. Auxiliary elements are pressure and temperature sensors, as well as electric heating elements. This, in the case of hot water helps to maintain its temperature at a given level.

Power compact platelet heat exchangers and benefits

Versatility is a significant advantage of the buffer capacity. By and large, this device does not matter from which source the coolant will come:

- a gas

- solid fuel heat exchangers

- solar collector

- heat pump

- from an electric heating element.

Significant advantage is the material and resource benefit that the users of such equipment receive. For example, with a heat exchangers capacity of 15 kW and a heat exchangers volume of 500 liters, half a ton of hot water will be common by a family or office space.

Higher efficiency of generators of heating networks (compact platelet heat exchangers) is easy to achieve by installing a storage tank in the system. Its second name fully explains the purpose of the equipment - a heat accumulator. It makes it possible not only to reduce the cost of heating the room.

Compact platelet heat exchangers and operating principle

Technically, a storage tank is a volumetric tank with thermal insulation, inside of which a certain amount of thermal energy enters. For the coolant to circulate, pumping equipment necessarily connects to the system.

If necessary, energy is common to bring water to the required temperature or to heat the room. The meaning of the buffer capacity is not only to accumulate, but also to keep the temperature within the maximum limits.

What factors differs in compact platelet heat exchangers?

- First and foremost; its volume and size

- Secondly, vertical, or horizontal mounting position

- Moreover, the presence of internal tanks and tank insulation

- Finally, Number of coils

An overview of construction types in storage tanks

There are several types of construction. The equipment is easy to produce completely hollow, with one or more internal coils, as well as with integrated compact platelet heat exchangers. This allows it to be common as a unit for hot water supply and heating.

In the first case, we are talking about the least expensive models that is easy to conenct to one or more heat sources. Additional functionality - protection against overheating of the coolant. A container with coils included in the kit allows the equipment to be common in more areas.

Tanks having compact platelet heat exchangers

Some tank model implies continuous hot water supply, connection to solar collectors and the use of excess thermal energy for other purposes (greenhouses, etc.). Tanks with heat exchangers can be common in open and closed heating systems, as well as for heating domestic water.

With the correct selection of the ratio of the capacities of the main heating unit and the storage tank. It becomes possible to cut energy costs in half. It is possible to load the furnace not twice a day, but once - the rest of the time, the battery will maintain the desired temperature.

Materials common to make a heat accumulator

The base - the tank - can be made of stainless or black steel. To prevent corrosion, the inner surface enamels with a primer mixture. To preserve the thermal insulation properties, the compact platelet heat exchangers comes with a thermal layer that prevents heat loss.

The scope of use of battery capacity is practically unlimited: they are successfully mounted and effectively perform their functions both in private houses and in commercial areas: in hotels, office buildings, catering establishments, etc.

Pairing devices for heat exchanger

Following are the devices types that can easily be paired with compact platelet exchangers.

1-Gas generator heat exchangers

It is important to combine such a tandem with either the installation of a condensate drain or exclusively with the cyclic operation of the heat exchangers equipment itself. The fact is that during its operation, gases are released that form condensate in the pipeline.

The principle of operation is as follows: while the heat exchangers stops, the thermal accumulator will be able to independently compensate for the lack of temperature.

2-Solid fuel compact platelet heat exchangers

Installing a storage tank in a heating system with a solid fuel heat exchanger makes it possible not to waste, but to retain excess heat during its operation.

The tanks can support the comfortable operation of the compact platelet heat exchangers for up to two days in winter and up to five days in the off-season. Or when common purely for hot water supply.

3-Electric heat exchangers

Reducing electricity bills is the most tangible plus of the additional use of battery capacity. When using a multi-tariff meter and turning on the heat exchangers at night, you can significantly save money, since in the daytime heat will come from the storage tank.