Compact porous micro-fluid channel plate for heating systems is one of the areas of use for units of this type.

Previously, shell-and-tube channel plates were the leaders in the design of industrial and civil facilities. Such devices have high power ratings. However, they occupy a huge area, do not lend themselves to inspection and cause preventive maintenance problems.

Plate heat exchangers have become a real godsend in this direction. The development of technologies has significantly reduced the difference in power compared to shell-and-tube units, and the compact dimensions, the possibility of inspection, ease of disassembly and cleaning have increased the demand for plate channel plate.

In the corresponding section of our catalog, you can see the range of similar units, as well as buy a compact porous micro-fluid channel plate for heating. Further in the article, their purpose and principle of operation are discussed.

WHAT IS A HEAT EXCHANGER IN A HEATING SYSTEM FOR?

The heating system of an apartment building or office building can be:

- dependent - an outdated version in which heat exchangers are not common

- independent - a modern type, plate heat exchangers are common to implement such a system.

Dependent heating system

- The principle of operation of a dependent heating system

- Similarly, the principle of organizing a dependent heat supply scheme

In a dependent system, the heat supply circuit between the heat source (boiler room or CHP) and the consumer is a single whole.

The coolant with a temperature of +95 ° C enters the house, where it goes through internal communications to the radiators of the end consumers - the apartments of the residents. Moreover, having given off heat, the coolant returns to the boiler room through the return flow.

How does compact porous micro-fluid channel plate work?

If the temperature at the entrance to the apartment building is higher and is +105 ° C, then to lower it to the required value, an elevator assembly and a jumper are common. With their help, the cooled coolant is mixed from the return line to the one entering the house.

The use of an elevator unit and a lintel in a dependent heating system

Using the elevator and lintel

The advantages of compact porous micro-fluid channel plate implementation scheme:

- ease of implementation

- Similarly, low cost of components

- Moreover, easier to maintain.

Cons:

Old pipelines of a long length, going from the boiler room to the consumer, rust. Therefore, the water entering the heating system of the house contains a large amount of precipitation and aggressive inclusions.

This leads to the rapid deterioration of modern aluminum heating radiators in apartments, as well as plastic pipes that have replaced obsolete cast iron pipes in the internal communications of residential buildings and office buildings;

In case of accidents at the coolant supply section, the consumer is left without heat

During sharp weather fluctuations - it is difficult to regulate the temperature level on the consumer's side, which leads to excessive heating of the premises and overpayment for utilities.

To eliminate the shortcomings of dependent systems, independent ones are actively introduced.

Independent compact porous micro-fluid channel plate systems

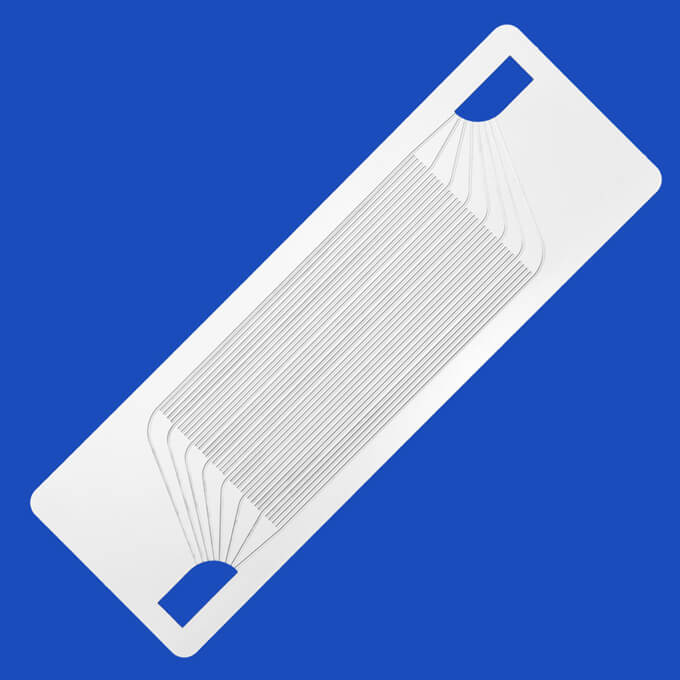

The main purpose of recuperative heat exchangers is to exchange heat between two different media at different temperatures without mixing them.

Therefore, the use of compact porous micro-fluid channel plate in heating systems allows you to divide the heat supply circuit from the heat supply organization to the consumer into two non-communicating parts, where through the contact surface - plates; heat is exchanged without contact between the media.

Such a heat supply scheme looks very simplified as follows:

- The principle of operation of an independent heating system

Independent heating system

This diagram does not take into account many additional elements, for example, a make-up pump. It connects to preserve the amount of liquid in the house circuit. In general, the work of such a system looks like this.

Pros of an independent compact porous micro-fluid channel plate system:

Purity of hot water in the home heating circuit is important. Furthermore, this allows the use of plastic pipes and aluminum radiators;

In case of accidents on the heat supply line from the heat supply organization to the plate heat exchanger, using a circulation pump, the flow rate of the coolant can be controlled. Furthermore, this allows you to keep the indoor temperature at the required level for some time;

High energy efficiency (up to 40% compared to a dependent system) due to temperature control at consumers, as a result - saving money on utility bills.

Cons:

- more expensive to implement;

- Similarly, more difficult to maintain.

HOW DOES A HEAT EXCHANGER WORK IN A HEATING SYSTEM

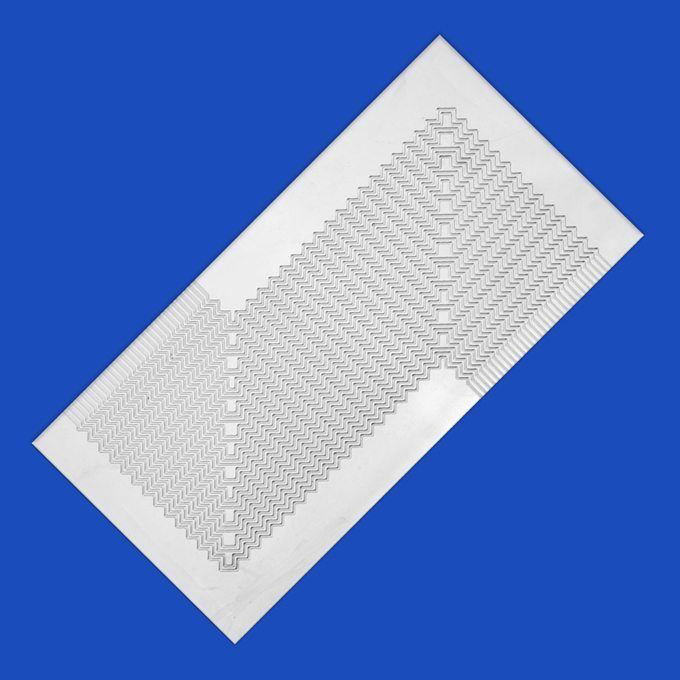

Scheme of operation of compact porous micro-fluid channel plate in a heating system

Heating circuit through a heat exchanger

The principle of operation of a plate heat exchanger in a heating system is as follows:

From the boiler room, the heated coolant enters the heat exchanger.

Thermal energy transmits through the plates to the heat carrier in the consumer circuit with an efficiency of up to 95%.

Further, the heated water flows through pipes to end users into heating radiators.

The spent coolant enters the return flow of the heat exchanger at a lower temperature. Here, again passing through the compact porous micro-fluid channel plate, it heats and enters the batteries.

The speed of movement of the coolant in the internal circuit is regulated by a circulation pump, which is installed on the return line.

How to avoid mistakes in compact porous micro-fluid channel plate?

In order to compensate for the loss of the coolant in the internal heating circuit, make-up pumps are common. It takes part of the water from the return flow of the external circuit going to the CHP or boiler room.

Since the amount of make-up material is small in relation to the main coolant in the house heating system, the quality of water in the pipes of a residential building does not deteriorate during the entire heating season.

In the operation of an independent heating system, various automation and control valves are common to constantly maintain the required characteristics: temperature, speed of movement of the coolant, pressure drop.

CONCLUSION

It makes sense to consider detailed diagrams for connecting plate installations. It comes in heating systems only in conjunction with a hot water supply system. In modern heating and water supply these two close processes.

Therefore, in subsequent articles, the use compact porous micro-fluid channel plate for hot water supply will discuss.