Why should you clean cracked heat exchangers?

The cracked heat exchanger is quite important equipment, almost every factory has it. It is common in a plastic factory, soft drink factory, dairy factory, textile factory, etc. Some applications heat exchanger such as heat - cold, evaporation - condensation, heat recovery, pasteurization, and sterilization.

Classification of the cracked heat exchanger by structure:

- Firstly, tube light chum

- Secondly, form coils

- Plate form

- Finally, winged tubular

Why clean heat exchanger scale?

A cracked heat exchanger is a device common to exchange heat between one or more heat carriers. These heat carriers are separated by surfaces to avoid mixing, known as heat transfer surfaces.

The heat transfer surface is usually maximized and is made of good and durable heat-conducting materials such as copper, stainless steel, etc. It increases the efficiency of heat exchange between the mediums.

Problems related to cracked heat exchangers

After a long time of operation, the heat transfer surface of the device will be dirty, scaled, etc., reducing the efficiency of heat transfer, leading to the following problems:

- the medium is not hot enough, not cold enough, not satisfactory

- Large energy loss for heat transfer, wasting energy.

- With a scale layer of only 0.5 mm, it reduces the heat transfer efficiency of the device

Cleaning the cracked condenser

We recommend that cracked heat exchangers when operating continuously should be cleaned periodically manually once a month or chemically every 6 months to ensure the equipment's performance.

So what will your company gain from cleaning the condenser:

- Saving wasted energy (like the example above is 15%).

- Saving maintenance and repair time

- Stable operation system, guaranteed product quality

Cleaning methods of heat exchanger: -

Manual cleaning: equipment must be disassembled, may cause damage to equipment (especially plate cooling), time-consuming and labor-intensive. Cleaning with chemicals: the optimal solution without disassembling equipment to help reduce labor and cleaning time.

In drying techniques, people often use two types of calorific to heat hot air. Calorific gas steam and gas calorific smoke. Provides plate cracked heat exchanger, tube, and drum rotation. Reputation and full category of equipment and spare parts.

1. What is a calorie heat exchanger?

In drying techniques, people often use two types of calorific to heat hot air: calorific gas steam and gas calorific smoke. For system drying systems people use gas-vapor calorific. Calorifer gas-vapor is a cracked heat exchanger, with a structure of the main parts as follows:

- Metal shells covered with equipment

- Heat exchanger tubes, usually aluminum wings.

- Connected flannels, seamless seams, and seamless pipes.

Types of calorifer heat exchangers:

There are two types of the calorie heat exchanger. Firstly calorific gas heat exchange secondly, aluminum wing cracked heat exchanger pipe parameters. Here are some details about the aluminum wing heat exchanger.

- Firstly, length from 3-6m

- Secondly, the internal diameter is Ø 25.4mm

- A 179 casting steel pipe material

- Moreover, thickness 2.77mm

- Also outer diameter Ø55mm

- Aluminum wing material A1 / 1060

- Finally, 0.41mm aluminum wing thickness

- What is the air dryer?

The air dryer is a cracked heat exchanger common in the boiler. The main operating principle of the air set of the air dryer is the heat transfer process from the boiler. The air before putting the air into the boiler combustion chamber serving the firing process.

- Firstly the air temperature starts from 30 degrees C and ends up to 120 degrees C

- Secondly, heat exchanger tube material: SS 400 welded steel pipe: φ60 x 2.5 mm.

- Shell material: SS400 steel plate - 4mm thick.

- Also, frame materials: SS400 shaped steel (I120, U120 ...).

- Moreover 1-layer anti-trust paint.

- Finally, 50mm thick insulation covers.

Benefits of air dryer in heat exchanger

Take advantage of the waste heat of boiler smoke to raise the air temperature for the boiler. The heat that the air carries will work to help fuel continue to dry in the combustion chamber and the combustion process will occur quickly More and more efficiently.

Along with other cracked heat exchangers in the boiler such as a water heater, the air dryer takes heat and reduces the temperature in the boiler smoke. Help the device to handle exhaust boilers to operate more efficiently and longer working life.

- Water heater for cracked heat exchanger

Fires for boilers are high-quality steel exchangers, good heat exchangers of anti-oxidation and high corrosion, with standard designs that help exchange and make maximum use of hot air. From boiler smoke, simple installation, not frequent cleaning.

The use of water heaters for boilers to save fuel reduces the cost. Moreover, a water heater in a cracked heat exchanger will reduce the waste smoke temperature to make the space around the boiler - a cooler boiler

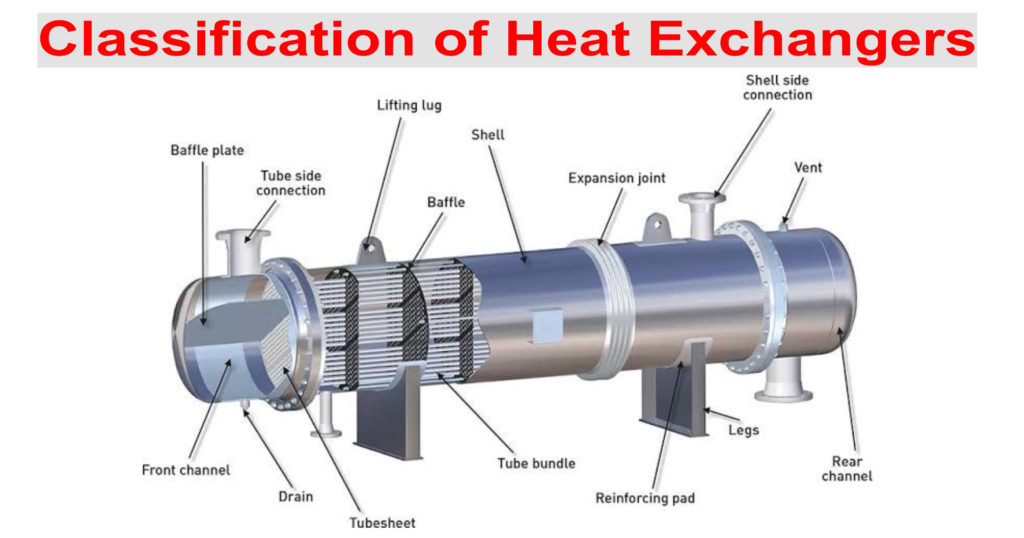

Equipment structure

The shell tube heat exchanger is the oldest tradition in the field of the cracked heat exchanger, including a beam of multiple tubes. These tubes are positioned together on the floor, which is then inserted in metal cylindrical pipes.

Often, highly corrosive or toxic substances in the environment will move in the heart. The structural arrangement of pipes creates many other messes: 1 line (1 pass), 2 lines (2 passes), 3 lines (3 passes), 4 lines (4 passes),) different types of hyphens are common for different shapes.

Teachnical features of cracked heat Exchanger

- Firstly, the shell material (body): copper/copper, aluminum/aluminum casting stainless steel.

- Secondly, pressure: up to 160 bar

- Heat resistance of cracked heat exchangeris: up to 350 ° C

- Also flow: from 0.1 to 3,500 m3 / hour

- Viscosity treatment: up to 1,000,000 shares

- Moreover, connection type: flange, lace tube, rich-co, tube clamp

Benefits of cracked heat exchanger

- High strength thanks to firm texture

- Also, cracked heat exchangershave fewer spare parts

- Suitable for high viscosity products, granules, and fibers (up to 75mm),

- High irritable, high-voltage, or vacuum applications and very high temperatures

- Moreover, easy to remove cleaning and maintenance

- Finally, high heat transfer efficiency

Summary

It is very easy to get quality equipment online in China. There are many suppliers and manufacturers who can ensure seamless delivery. But, we cannot ignore tha fact that only professional companies can maintain standard.