What is Micro Channel Plate?

Custom Micro Channel Plate, in industry, is generally common to extract heat from one fluid stream and add it to another, thus performing heat exchange. Both for heating and cooling fluids, it is common to use plate micro channel plates in these processes. Therefore, there are two models of plate micro channel plates: brazed plates and collapsible plates.

The difference between them is basically in their constructive format, where the first, as the name implies, is brazed, that is, sealed. It is a consumable that does not involve maintenance, only cleaning and replacement when necessary, however, custom Micro Channel Plate has an extremely efficient thermal exchange.

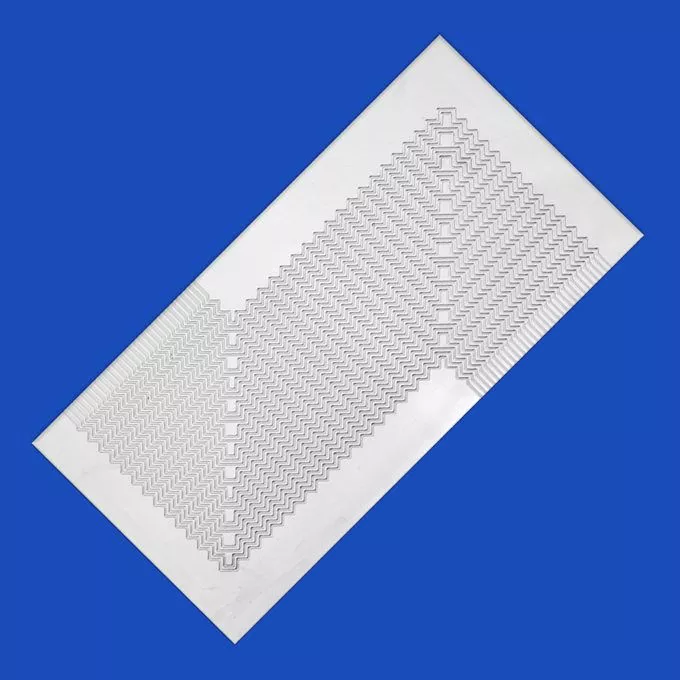

The Structure of custom Micro Channel Plate

In this way, in a small space, it is possible to exchange a large temperature delta, facilitating operation and reducing costs.

In turn, the detachable plate micro channel plate has spare plates and gaskets. Therefore, it adds greater design flexibility. In this way, it will be built exactly to meet the customer's project in question, with flow and temperature data being tailor-made for that process.

How do they perform the heat exchange?

Micro channel plates are common in both sanitary and non-sanitary industrial processes. Thus, they can be present both in the heating of water in a refrigerator – for use in scalding or other sterilization processes and in the reception, heating and cooling of milk in small, medium and large dairies.

In addition to the food sector, the use of custom Micro Channel Plate is common in the plastic and metalworking industries. This is because processes such as oil cooling use this equipment. In addition, they are useful to maintain their stability within the equipment, regardless of factors external to the process.

The maintenance of the demountable plate micro channel plate is relatively simple and it is easy to carry out either by contracted third parties (installer or maintenance technician).

Stollpche Custom Micro Channel Plate

Stollpche offers a wide range of micro channel plates in a modular, platform-based system with high quality components. In this way, you can define both the capacity and the connections your application needs. In addition, they are compact and take up little space.

Among all the advantages they can offer to your processes, low operating costs and very high performance stand out. In addition, they are ideal even for systems that have large variations in temperature and constant or variable pressure.

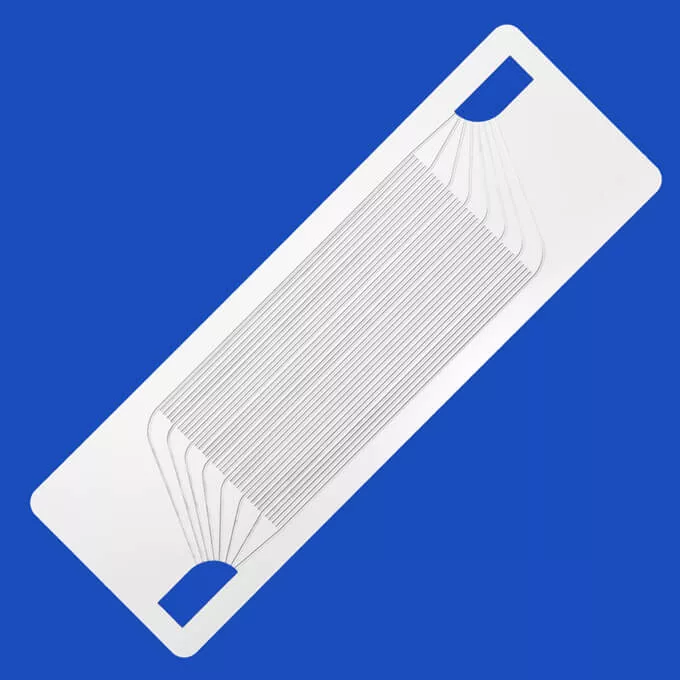

BPHE and MPHE – Plate Micro Channel Plates

BPHE and MPHE brazed plate micro channel plates are ideal choices for chillers and heat pumps, among other applications. They can be common as evaporators, condensers, economizers and other purposes. Therefore, custom Micro Channel Plate range capacity is high, ranging from 2 to 200 kW.

These plate micro channel plates design to combine high thermal efficiency with energy savings, making them a great choice for those looking for energy efficiency.

Among its features stand out its robust and compact design, which allows flexibility in size? It also offers a wide variety of connections and savings in refrigerant consumption. In addition, it is 100% inspected and in accordance with all current regulations.

Greater Flexibility and Greater Savings

The Stollpche custom Micro Channel Plate is another excellent way to increase your savings. Also with a robust and efficient design, it works effectively in a wide range of applications. The innovative concept of the channels on its plates makes it one of the best micro channel plates on the market, thus significantly reducing energy consumption and reducing CO2 emissions.

Micro channel plate has a capacity of 20-90 kW and is suitable for evaporators, condensers and single-phase applications. Thanks to its “two in one” connection, installation is easier. In addition, its plate pattern with microplate channels allows for greater thermal exchange, reducing weight and refrigerant charge.

The Capacity of Custom Micro Channel Plate

Most micro channel plate models have the possibility of increasing the capacity. Therefore, this process is easy to do through the study of the application of the equipment and the project of resizing the set of plates.

Check out some advantages of increasing the capacity of micro channel plates.

Restructuring of the Micro Channel Plate

From the renewal of the set of plates and gaskets of the micro channel plate, it will occur in order to guarantee a longer useful life of the process.

Lower Cost of Future Replacement of Plates and Gaskets

Considering the plate and gasket set, the cost and availability of replacement will be constant, reducing future maintenance costs. In addition, it guarantees availability in case of corrective maintenance of the Custom Micro Channel Plate due to water hammer or other external factors.

Smaller number of boards compared to other manufacturers, due to the larger exchange area per board

Stollpche plates have the largest exchange area of any micro channel plate available on the market. In this way, a smaller number of plates are best for the same exchange to occur in relation to other exchanger models, for example.

The Old Micro Channel Plates in Exchange Negotiation

In negotiation, the plates of old micro channel plates are easy to acquire as an exchange and part of the business, thus generating great savings in the replacement process. This uses the same structure, changing only the set of plates and gaskets.

The physical structure of the Custom Micro Channel Plate that maintains the plates and the entire system is easy to reuse. In this way, the switching cost is infinitely lower. With fewer expenses, the feasibility of exchanging the board set is, of course, more recurrent and well regarded within the industry.

Complete Replacement Increased Performance

The increased performance of Stollpche micro channel plates combined with the reduction in maintenance and operation costs ensure greater energy delivery than other models, delivering better results, both in operation and production.

Simple Heat transfer

The working principle of heat transfer is simple. That way, hot fluids have to enter through the top, always.

One is that hot fluids tend to have a lower specific gravity. Thus, Custom Micro Channel Plate remains on top of equipment. In fact, cold fluids are denser, heavier. Its natural tendency is then to remain at the bottom. We can say it was an application of steam and water.

We have cold water inlet from below. This would be the working principle of the exchanger. So, we have here exemplified laterally hot fluid cold fluid.