What are Different Diffusion-Bonded Type Heat Exchangers?

Want to know what are diffusion-bonded type heat exchangers? This guide will tell you everything you need to know about different types of diffusion-bonded heat exchangers. So, keep reading!

Introduction

A diffusion-bonded heat exchanger is a machine that transfers heat from one source to another. The diffusion bonded heat exchanger transfers heat with the help of conduction. The process of conduction takes place through the exchanger materials. To complete the process, the manufacturers even use a separate medium. The function of a shell and tube heat exchanger is to pass the fluids through the tubes. There are various diffusion-bonded type heat exchangers available out there. That’s because different situations require different heat exchangers.

Can You Diffuse Fluids With Diffusion-Bonded Type Heat Exchangers?

It is not impossible to diffuse fluids with diffusion-bonded type heat exchangers. But, the appropriateness of a liquid with a warmth exchanger will rely upon the sort of warmth exchanger being utilized and the materials which are accessible. Standard Thermex Warmth Exchangers are appropriate for most liquids including Oil, Water, Water Glycol, and Ocean Water. For more destructive liquids like chlorinated saltwater, refrigerants, and acids different materials, for example, Treated Steel and Titanium should be utilized all things being equal.

The Process of Designing Diffusion-Bonded Type Heat Exchangers

If you want to design diffusion-bonded type heat exchangers, then there are some important factors that you must consider first. But, you must keep in mind that these requirements are very basic. That’s why you should also inquire about pressure loss limitations and other special requirements. Let’s take a look at these considerations below.

- The first thing that you must consider is the primary circuit fluid type. In addition to this, temperature and flow rate are also very important.

- You must also know what you need to take out of the primary circuit as well. You should decide whether you need to take out the target outlet temperature or heat dissipation.

- Temperature, flow rate, and secondary circuit fluid type are also very important.

What are Diffusion-Bonded Type Heat Exchangers?

There are different diffusion-bonded type heat exchangers out there. Want to know more about these types? Continue reading then.

1. Plate Type

The plate type diffusion bonded heat exchangers work almost the same as shell and tube heat exchangers. The only difference is that there is that it does not use tubes. It uses stacked plates instead. Moreover, the plate heat exchangers use brazing as well. But, it entirely depends upon the fluids and applications that it uses. What makes these heat exchangers an ideal choice is their compact stainless steel composition. For this purpose, they are extremely popular among refrigerants or food and beverage processing.

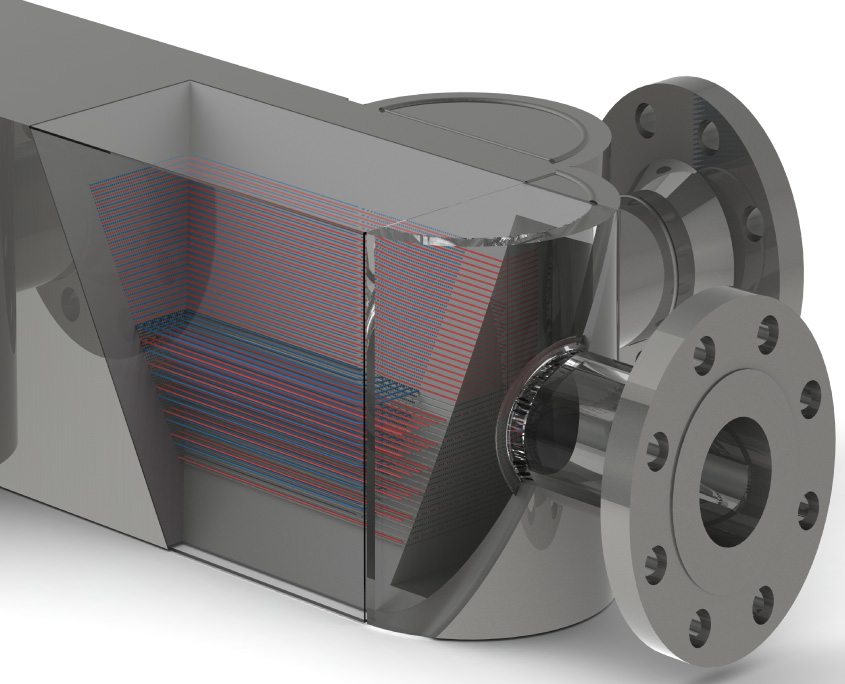

2. Shell and Tube

Shell and Tube diffusion bonded heat exchanger consists of small tubes in extremely large numbers. These small tubes are located in a cylindrical shell. For this purpose, this type of diffusion bonded heat exchanger is known as Shell and Tube. The manufacturers position the tubes in a cylinder with the help of a tube stack or a tube bundle. They either use fixed tube plates or thermal heat exchangers. While fixed tube plates are fixed permanently to the body, the thermal heat exchanger uses a floating tube stack. The floating tube stack found in the thermal heat exchanger helps the tube bundle to expand and contract no matter what the varying heat conditions are. As a result, it allows easier removal of tube bundles for service and maintenance.

3. Air Cooled

The next type of diffusion bonded heat exchanger is the air-cooled type. Their use is extremely common among vehicles and mobile applications. That’s because they do not use any cool water source. Thermex plans and supplies blend cooling packs (or combi-coolers) which join a motor coat water cooler, oil cooler, and charge air cooler into a solitary unit. It diminishes space necessities and improving effectiveness. The fan or wind transports a cool air current brought about by the development of the vehicle.

Some Tips for Making Diffusion-Bonded Type Heat Exchangers More Efficient

Looking for some tips on making your diffusion-bonded type heat exchanger more efficient? Let’s check them out below.

1. Installation

As a rule, the most proficient approach to introduce a warmth exchanger is with the liquids streaming in a counter-flow plan. For shell and cylinder heat exchangers the coolant ought to enter at the least channel position to guarantee that the warmth exchanger is in every case brimming with water. For air-cooled heat exchangers, it is critical to consider the wind current when introducing a cooler. Any piece of the center will bargain the cooling limit.

2. Flow Rate

Another significant factor is the progressions of the liquids in both the essential and the auxiliary sides of the warmth exchanger. A more noteworthy stream rate will build the ability of the exchanger to move the warmth; however, a more prominent stream rate additionally implies more prominent mass, which can make it harder for the energy to be taken out just as expanded speed and pressing factor misfortune.

3. Temperature Differential

The contrast between the hot liquid and coolant is vital when planning a warmth exchanger. The coolant in every case should be at a lower temperature than the hot liquid. Lower coolant temperatures will remove more warmth from the hot liquid than hotter coolant temperatures. On the off chance that you had a glass of drinking water at room temperature, for instance, it is significantly more compelling to chill it off utilizing ice instead of simply cool water; a similar standard applies to warm exchangers.

Final Words

This was your comprehensive guide on diffusion-bonded type heat exchangers. Different situations require different heat exchangers. The diffusion bonded heat exchangers are very important in the process of diffusion bonding. For this purpose, it is extremely important to have complete knowledge of them. Looking for more information on diffusion-bonded heat exchangers? Contact us now!