Hello dear readers of the site ural-mep.ru. Today we will consider what materials are common for the manufacture of heat exchanger technology. Those. from what, from what rolled metal or grades of steels or alloys these or those parts are made.

Learning outcomes of tubular heat exchanger technology

- How often do you need to repair heat exchangers?

- What tools are required to clean heat exchangers

- Repair procedure for heat exchangers

- How to replace the heat exchanger tubes

- How to choose a tool for repairing heat exchange equipment

These are the areas; on which you have a sound grip by the completion of this article on; heat exchanger technology.

What is heat exchanger manufacturing technology?

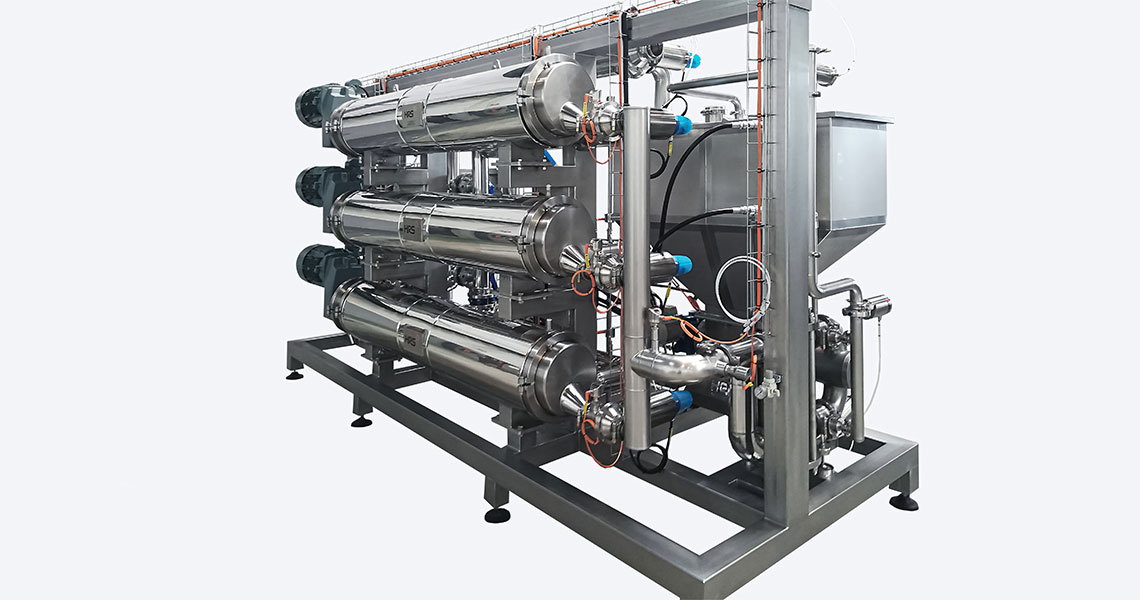

The question arises: "What materials should be common for the manufacture of certain parts of heat exchange devices"? Today I will try to answer you to it. And so, everything is in order. Among multiple types of technologies that can be common for this purpose, tubular heat exchanger is best.

Selection of materials for mb and mbm shell-and-tube heat exchangers

A heat exchanger technology is needed to ensure a given level of heat transfer between the media. To do this, you need to make a thermal calculation of the shell-and-tube heat exchanger. Let's see everything concretely and thoroughly with examples. Moreover, the oil moves at a rate of 25-37 tons per hour.

To repeat, the data are oil inlet and outlet temperatures and oil consumption. In addition, there are auxiliary data, this is the temperature of the cooling water, it should be no more than 33 ° C and the water consumption.

An overview on devices of heat exchanger

The main device of the mb-type shell-and-tube, heat exchanger technology has been developed for a long time, but some parts and assemblies can be made more efficient, and the apparatus itself is cheaper, more maintainable, and not expensive.

And so, the initial conditions are given and the construction is common to us. Let's consider right away from the point of view of the formation of an effective apparatus. The oil cooler is a conventional shell-and-tube apparatus, the device of which is easy to see in the material for the design of a shell-and-tube heat exchanger.

Considerations of materials of heat exchanger

The material from which it is made must have a sufficient coefficient of thermal conductivity for reliable operation. Then the cost of manufacturing the beam of heat exchanger technology should be as low as possible for the previously common grades of steel or alloys. Again, this depends on the material chosen.

1-Pipe system

Then the pipe system must work with a given efficiency throughout the entire service life, and this again depends on the material and its structure. For the manufacture of the pipe part of the conventional oil cooler mb, brass or stainless steel grade 12X18H10T is common.

2-Brass tubing

The brass tubes are smooth, and the stainless-steel tubes profile itsel. Moreover, the latter are more effective, you can read about it, if necessary, here. In short, the profiling of the tubes improves the heat transfer processes by organizing the flow of fluid movement.

Moreover, in heat exchanger technology this tubing prevents the formation of deposits on the surface, which further increases their service life. In addition, stainless steel works longer and more reliable.

Tubular heat exchanger manufacturing technology

The efficiency of such a solution is on the order of more than 15%, this is due to improved heat transfer, but here it is also important that such a tube works longer and can be common with clogged water. In general, the choice on the side of the material for a heat exchanger technology is a stainless-steel pipe 12X18H10T

We have considered the main unit, but there are also other parts, these are tube sheets, housing, chambers, nozzles. Everything is simple here. If the cooling water is fresh and without impurities and high salt content, then all of them are made of ordinary carbon steel st3sp, st20 and alloy steel 09g2s. Those.

What are the features of the device and principle of operation?

The composition of the parts of the tubular units is as follows:

- Tubes fixed on special racks

- Compensator

- Lid (located on the side)

- Thermal insulation (equipped under the exchanger)

- Tightness comes by special clamping rings

The principle of operation and its features

- Generally, removal of liquid masses directly through the coolant

- But first, the substance flows through the inlet into the unit

- Moreover, the time it takes for the liquid to cool very much depends on what temperature it was initially

- Similarly, this happens after flowing of substance through the nozzle

- In addition, the length of the pipes and their width (diameter) will certainly affect cooling rate.

Types of tubular heat exchangers

Today, the range of heat exchanger technology comes by the following types:

- Combined - tubular-plate

- In addition, crossflow, direct-flow, or counter-flow

- Vertical and horizontal

- Furthermore, narrow compensator, wide compensator without compensator

- With double thermal insulation

- By the number of pipes - about 6 or about 8

The first version of the installations showed itself on the positive side as a high-performance device. It is often common in areas such as pasteurization of juices. At the same time, it uses narrow tubes, steel covers, and the whole structure is mounted on three strong posts.

how often it is necessary to repair heat exchangers, consider what tools are required to clean the heat exchangers and the procedure for work. We will also select a tool for the repair of heat exchange equipment.

Common defects in heat exchange technology

- Damage to supports, threads on fasteners, moisture, or damage to thermal insulation

- Similarly, damage to sealing surfaces, cracks in body parts and pipes

- Dents, leaks, and gaps in tube expansion in tube sheets

- Moreover, increasing the diameter of the holes in the tube sheets, pitting and intergranular corrosion.

- In addition, reducing the thickness of the pipe wall, bottom, body

- Fistulas in welds

For the smooth operation of heat exchanger technology, it is necessary to carry out repairs on time and according to the regulations. Below we will analyze how often a complex of repair measures needs to carry out.

Heat exchanger repair cycles

Heat transfer equipment requires ongoing maintenance repairs. Due to uneven wear and accidental damage, various repairs are important.

The repair periods for heat exchangers depend on two factors:

- Type of production.

- The type of heat exchanger.