Introduction to Printed Circuit Heat Exchanger Design

To fully understand the printed circuit heat exchanger design, you need to have the basics of the technology. A heat exchanger, as the name suggests is a system that is used for the exchange of heat between 2 or more fluids. These are popular in refrigeration, air conditioning, power stations, space heating, natural-gas processing, and sewage treatment, etc. The 2 fluids (liquid or gas) have varying temperatures, one is hot and the other is cold. There are 3 ways the 2 fluids can flow in a heat exchanger, they either flow in parallel to each other, or in the cross flow where they enter from opposite ends, or the counter current flow, where the fluids cross over each other. There are multiple types of heat exchangers. Printed Circuit Heat Exchangers (PCHEs), also known as Plate Heat Exchangers, is one of the types of heat exchangers that we are going to be discussing in this article.

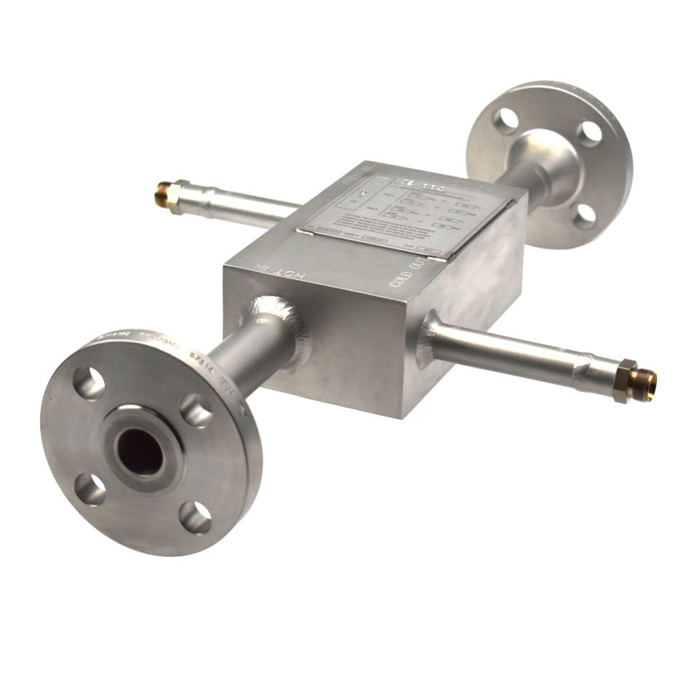

Printed Circuit Heat Exchanger

A Printed Circuit Heat Exchanger also known as a Diffusion-bonded Micro-channel Heat Exchanger, is made from thin and flat metal plates. Onto these thin and flat metal plates, you use chemically engraving for the “fluid flow channels. These channels are the ones through which the fluid will flow. There are separate channel designs or patterns for the separate hot fluid and cold fluid. For etching purposes, you need separate metal sheets for hot and for cold fluid. However, there are sheets that you can use for both hot as well as cold fluid. Next, stake the metal plates onto each other alternatively. Ensure to follow the order cold, hot, cold, hot, and so on.

Use diffusion bonding to bond the skated plates, thus resulting in a block of metal. These bonded metal sheets behave as a single metal block with holes running through it, after diffusion bonding. There is a need of several such blocks to achieve proper performance. Thus, multiple such metal blocks with fluid channels join together by welding to form an exchanger core of required dimensions. After the required exchanger core is made, an “interblock vent” between each block is created in the block to block weld to make sure no pressure is present inside. After this, finally, headers and nozzles are welded on, to form the complete Printed Circuit Heat Exchanger.

What is “diffusion bonding”?

Diffusion bonding or diffusion welding is the solid-state bonding method used in welding metals. You usually carry it out by applying high pressure along with necessary high temperatures on the material that requires welding. You use this technique in welding multiple alternating layers of metals sheets together.

How does the Printed Circuit Heat Exchanger work?

The Printed Circuit Heat Exchanger has an inlet nozzle and outlet nozzle from where the 2 different fluids can enter and leave, the hot medium and the cold medium. It is important to cool the hot ones while the cold one needs to be hot. The 2 mediums will enter the heat exchanger through their separate nozzles, and into the heat exchanger. The hot medium will enter the fluid channels for the hot fluid in the alternating plates while the cool ones will enter the other alternating plates, in the fluid channels for the cold fluid. Each plate has an alternating fluid channel pattern. The hot fluid flows into space between the alternating pairs of plates, and the cold fluid flows in the remaining alternating pairs of plates. Each of the two fluids enters and leaves by its associated nozzle.

The efficiency of Printed Circuit Heat

The flowing medium has a hot, cold, hot, cold pattern as they flow through the heat exchanger. It is important to completely separate the 2 fluids from each other. After that, ensure that they do not mix. As the metal plates are very thin and have a large surface area, this allows maximum contact of both the fluids and so maximum heat transfer rate. Moreover, the fluid channels are very small which ensures a very good thermal contact between the 2 flowing fluids which will also increase the efficiency for maximum heat exchange. Furthermore, the material that manufacturers use for the making of these plates has high thermal conductivity, which further increases efficient heat exchange.

Printed Circuit Heat Exchangers have the ability to withstand corrosion and erosive environmental conditions. They can be made from different materials (Eg. Metals, alloys, plastic) depending on their application. Printed Circuit Heat Exchangers are much more efficient than other types of heat exchangers. You can also easily control the heat exchanging capacity of these by regulating the valves, to increase or decrease the flow of fluids in them.

Advantages

These are ideal for high temperature and high pressure. Due to the diffusion bonding, there is a significant improvement in the operation of these Printed Circuit Heat Exchangers. They have extremely high pressure withstanding capabilities and high operating temperature ranges. They have high structural solidarity because their metal plates are now one solid metalcore. These are also lightweight, compact, and require less space in comparison to other types of heat exchangers. Moreover, they are highly resistant to vibrations, freezing, and catastrophic failure approach.

The Printed Circuit Heat Exchangers are popular in a wide variety of industries including; Gas generation: hydrogen and also PSA nitrogen, Renewable power: solar, geothermal, as well as wind (generator cooling), Synthetic fuels and also biodiesel, Combined heat, and power (CHP), Pharmaceutical, Onshore as well as offshore oil & gas, Cryogenic temperatures, Botanical extraction, Chemical production: ethylene, nitric acid, methanol, as well as propylene, etc.

The Printed Circuit Heat Exchangers are excellent for applications where a very high operating temperature range and a very high pressure withstanding ability are required in a heat exchanger. Moreover, it is also useful where you require small and compact heat exchangers as it is much smaller (almost 90% smaller) than other heat exchangers. The very small fluid channel pattern on thin metal plates that are bonded through diffusion bonding makes these much more efficient than other types of heat exchangers as well as it is very resistant to corrosion and other environmental conditions like freezing and vibrations.

In order to learn more about printed circuit heat exchanger design, please Contact US Today!