Individual selection without standardization of parameters is one of the key features of such a complex engineering device as a heat exchanger (The zigzag channel PCHE). With practically equal initial parameters of the same objects, the characteristics of the equipment can be strikingly different.

Therefore, a lot of different parameters are considered, which directly affect the final cost of the heat exchanger. It’s of great significance to take them in consideration while working on heating systems. This article will help you in this regard.

What data is required for the zigzag channel PCHE?

Primarily - the system in which the device will operate indicates: hot water supply, ventilation unit, air conditioning, heating, etc. When installed in a water supply system, even the number of water intake points is important.

It is because the device will have to work in the correct mode both in summer and in winter. Fluids, power, and temperature curves are important for use as an intermediate device and cooling supply. The power reserve is important, in the zigzag channel PCHE for which they take + 15-20%

Five parameters for calculating and ordering heat exchanger

- First, conditions the device will function include heating networks, boiler room, etc.

- Second, it’s common in various technological processes, ventilation organization, air conditioning

- Also, two main parameters for installation are at the inlet and outlet of the device

- Lastly, power is indicated in giga calories, kilowatts. Consider mass flow rate of medium

Important considerations regarding heat exchanger

All the required parameters contains in the technical conditions. This comes from the heat supply organization, in the contract with it, in the technical assignment from the engineer or technologist. Moreover, in the project of the heat point or the system where the heat exchanger comes to be common.

How is the cost of a heat exchanger formed?

The price of such a complex engineering product of the zigzag channel PCHE is a value depending on a huge number of parameters. It is not easy to calculate, say, by overall dimensions or scope of application, since most often production carries out on an individual request.

The price in this case forms only for components and work, but as a guide you can use an ergonomic calculator. It will provide an approximate price for the heat exchanger, the final version of which will be calculated by technicians upon your request.

Factors: the zigzag channel PCHE price is dependent on

- First and foremost; machine type

- Secondly, conditions of his work

- Finally, number of plates

Contact the specialists for a calculation on the zigzag channel PCHE now and get a detailed estimate soon.

Reducing energy consumption thanks to heat exchangers

Reducing financial costs by not reducing productivity but reducing energy consumption is smart. And it is quite logical that modern and highly efficient types of equipment, such as PROFESSIONAL plate heat exchangers, should be common for this.

Without exaggeration, the enormous saving of energy resources, regardless of the area in which they are common, is the level of the device managed to achieve by this manufacturer.

Difference between brazed plate heat exchangers and the professional brand?

Those who have come across this company at least once understand the whole global difference between their products, like the zigzag channel PCHE in contrast to competitors. To begin with, it is worth noting that there are two types of PTs: a set of plates in a frame and tubular types in a casing.

The design of the latter is different - its heating elements are made in a U-shape and are in a pipe in the form of a cylinder. The professional brand offers another model - a set of plates, which are in a frame like a so-called "sandwich". They form two channels that are independent of each other, due to which the transfer of energy from one working medium to another carries.

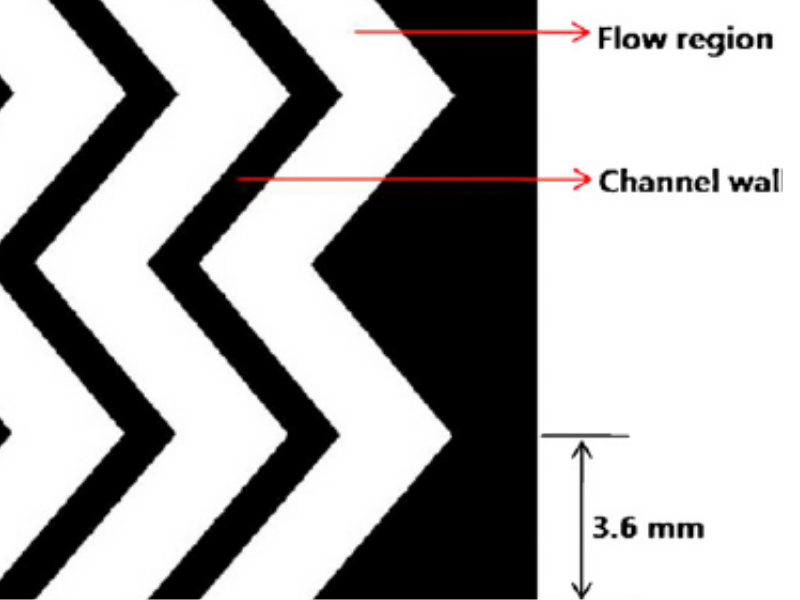

What is the difference in the zigzag channel PCHE?

The fact is that in the production of brazed plate heat exchangers, their welding carries out in a vacuum furnace. The result is a structure that is completely resistant to any type of functional environment, including those with a maximum temperature and a high degree of aggressiveness.

Features of professional brazed plate heat exchangers

In production, for the zigzag channel PCHE the metal soldering process is common. This is the melting of its layers, because of which they adhere tightly to each other. After that, the metal cools and "baked" in a vacuum oven - this allows you to completely and evenly cool the device and achieve its strength.

How energy consumption reduces?

To begin with, we should note that this is one of the key consumers making a choice in favor of plate-type heat exchanger. Reduced maintenance costs, acceptable starting cost determine the popularity of professional products. Minimal heat loss, high heat transfer capacity and small size.

These are the same parameters of the professional pt, due to which energy costs reduce. The brand provides a wide range of loads, minimized the risk of mixing two streams of the working medium, which distinguishes this type of equipment from tubular.

7 advantages of PPT from SVEP:

The zigzag channel PCHE is helpful in following aspect:

- Reliable - there is practically no need for regular maintenance

- In addition; long-term work without repair

- Self-cleaning effect - formed due to the high turbulence of the entire surface of the plates

- The risk of damage (internal components of heat exchanger) during cleaning reduces to zero

- Moreover, economy and energy efficiency due to compactness

- Last; versatility – is easy to apply in a variety of areas and industries

Summary the zigzag channel PCHE

The devices is easy to integrate into installations with a capacity of up to 1000 kW (we are talking about refrigeration equipment) and up to 20,000 kW for equipment in the field of heat and power engineering. At the same time, the minimum threshold of the range is only 1 kW.