Fireplace heat exchangers and industrial applications

In industries such as food, food processing, seafood, paper, textile, tobacco, beverage, etc., Fireplace heat exchangers play a very important role. They are considered to be highly productive and efficient devices

It is a device common to exchange heat between one or more heat carriers. Heat carriers can be separated by tubes to prevent mixing or direct contact between the heat carriers. In simple terms, a heat exchanger is a device designed to transfer heat from one part to another

Application of fireplace heat exchanger

The fireplace heat exchanger is commonly common in man and his environment they are common in all industries like wastewater treatment, refrigerator systems, wine-bare industries, and in the aircraft industry to make the aircraft fly during the flight.

It is an important device, widely common in many different fields. Here are some basic applications of heat exchangers. Ship Technology: Steam heating, vacuum condensing, camshaft oil cooling, seawater central cooling, and oil cooling.

Applications in chemical technology.

- Firstly, it is common to make EO/EG heat exchanger, VOC condenser.

- Secondly, high pressure and high-temperature waste heat recovery system.

- Common in Ethanol condensing system, heats cools and condenses a variety of liquids

- In refrigeration system. It evaporates or condenses NH3, R32, and R407 refrigerant gas.

Applications in HVAC systems:

The fireplace heat exchanger has many applications in the HVAC system and these are,

- Central water heating system, equipment to create hot water quickly using steam.

- The Inter concept building depressurizes uses a heat exchanger.

- Chiller Heat Recovery System.

- Moreover, solar system heat exchanger, heat pump.

- Paper technology: Waste heat recovery, paper coloring, etc.

Application of fireplace heat exchanger in different fields

Fireplace heat exchangers have many different uses and functions, so their application possibilities are endless. Due to product heating or cooling requirements. Or can be common for pasteurization, sterilization, preservation of food and beverages such as milk, and beer

- Textile technology: Heat recovery in the washing and washing process.

- Gas and coal: Cooling of ammonia, benzene, and heat recovery of CO2 evaporation.

- Power industry: Heat exchanger common to cool turbine oil using lake water, spring water.

- The heat exchanger in the solar system.

Classification of fireplace heat exchangers

Due to the wide variety of applications, fireplace heat exchangers can be classified according to their construction, application, the quantity of heat medium, the shape of the exchange surface, and type of flow. Specifically classification of heat exchangers based on the structure.

In addition, the fireplace heat exchanger can be classified according to its construction. And the classifications are Shell and tube heat exchangers, plate heat exchangers, Spiral heat exchangers, Twin-tube heat exchangers, Air-cooled heat exchangers.

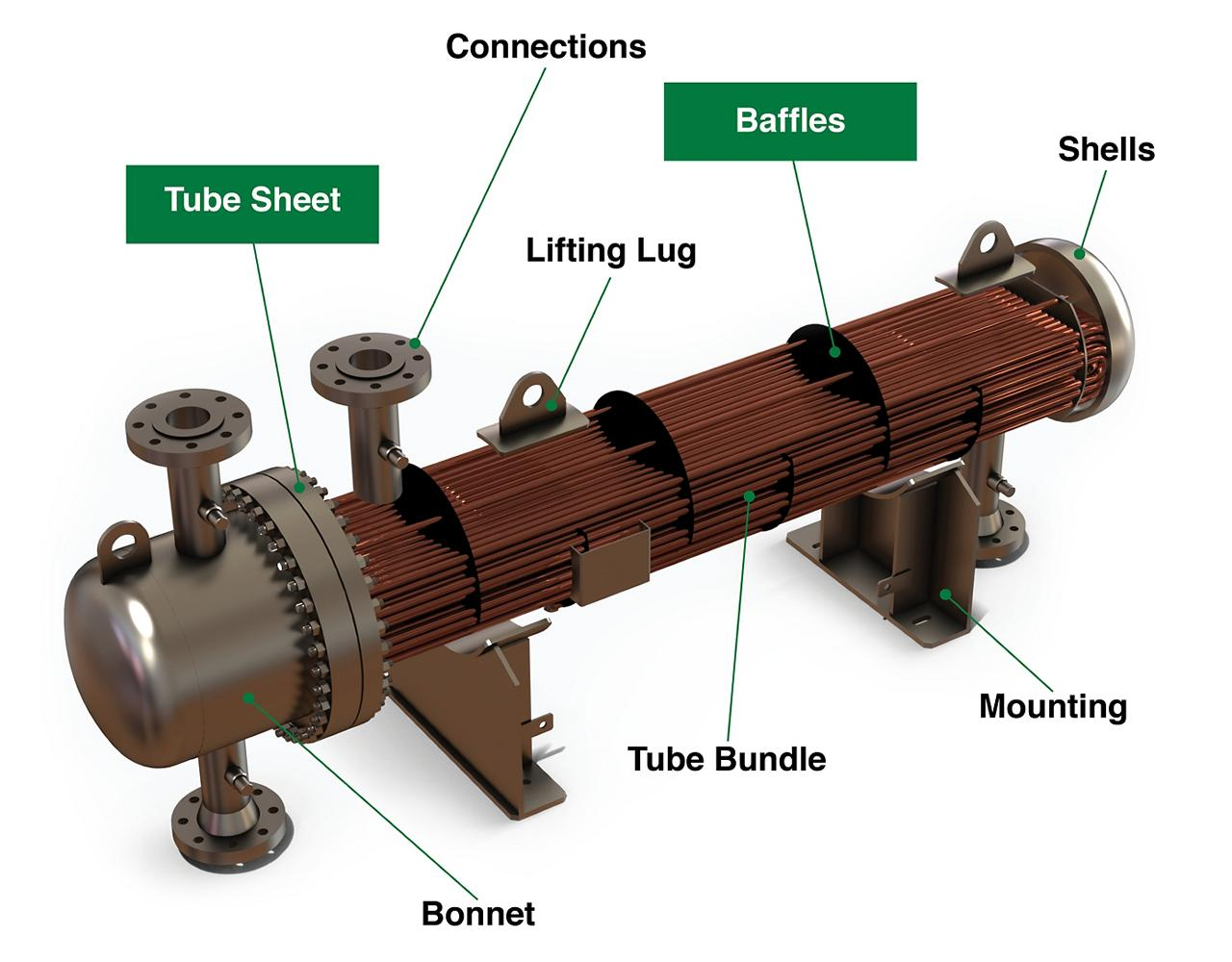

Beam tube fireplace heat exchanger

As one of the most widely common forms of fireplace heat exchangers in all industries, an estimated 60% of the world's heat exchangers today are tubular heat exchangers.

- The device has a bundle of tubes inside through which a liquid heats or cools.

- It is common for applications requiring high working pressures and temperatures.

- The heat exchange medium can be liquid, gas, gas, or vapor.

Characteristics of fireplace heat exchanger

The beam tube fireplace heat exchanger depends on several factors:

- Firstly, tube size: Using small tubes will reduce costs.

- Small tubes compact equipment, but conversely, it will be difficult to clean and dirty.

- The availability of spare parts and abrasion depends on the thickness of the pipe.

- Finally, Pipe length, the distance between pipes, baffles.

Plate heat exchanger and fireplace heat exchanger

A plate fireplace heat exchanger is a device that uses metal plates to transfer heat between two liquids. This has a major advantage over a conventional heat exchanger in that the fluids. And are exposed to a much larger surface area because the fluids are spread out across the plates.

The device offers large heat exchanger efficiency and small size compared to the beam tube type heat exchanger. Plate heat exchangers are mainly common for liquids operating at low pressures (below 30bar).

Applications of fireplace heat exchanger

Some special plate fireplace heat exchangers using welded joints can be common for high-pressure applications where the medium is gas or steam.

- Firstly, plate heat exchangers use the gasket.

- Secondly, a Semi-welded plate heat exchanger.

- Also, sealed plate heat exchanger.

- Moreover, spiral heat exchanger.

- Finally, plate coil heat exchanger.

Flat fireplace heat exchanger

The structure of the fireplace heat exchanger consists of flat walls separating the alternating heat exchanger refrigerants. Heat exchangers of this type are common for heat exchange applications between:

- Air

- Gas-Liquid.

- Vapor - Gas.

Application of flat fire-place heat exchanger

- The flat fireplace heat exchangeris common as an air Preheated

- Also heat Recovery

- Air Heater (Air Heater)

- Moreover, hot Air Generator (Hot Air Generator)

- Heat recovery (Recuperate), etc., maximum design temperature can reach 1000 ℃.

Classification of heat exchangers by application

Usually, a fireplace heat exchanger is common to exchange heat between two media with different temperatures. However, in many applications, the same device can be common to exchange heat between multiple media.

Typical examples are heat exchange between steam, water, glycol, and milk and juice in product heating and pasteurization applications Common heat transfer surface shapes include: Smooth surfaces (bare tubes), fined tubes, chevron herringbone plate surfaces.

Classification and diversity of fireplace heat exchanger

Fireplace heat exchangers are diverse, which can be classified based on many different ways. If the heat exchanger is classified based on the flow, it can be classified into 3 flows:

- Type 1 pass

In a single-pass fireplace heat exchanger, the liquid enters one end of each tube and exits the other. The surface condenser in the force plant is normally a straight cylinder heat exchanger Two-and four-pass plans are famous because the fluids can go in and out from the same side.

- Double pass

Each shell and tube device directs cooling water through its center tube. In such cases, 2-line heat exchangers area unit a perfect answer, as they need water and outlet fittings on a similar finish cap, permitting cooling water to enter and exit device within the same position.

- Multi-section.

The multistage heat exchanger has liquid flowing through multiple times through the use of U-tubes and baffles. The regenerative heat exchanger uses the same fluid for heating and cooling. Non-regenerative warmth exchangers utilize separate liquids for warming and cooling.

The choice of fireplace heat exchanger should be based on temperature requirements, flow rates, type of media, and specific applications. In addition, the type of material and the price of the heat exchanger are also decisive factors.

Designs of fireplace heat exchanger

Because the nature of each industry is different, heat exchangers are designed differently. Therefore, for the equipment to be common optimally, it is necessary to have the assessment and advice of experts in the industry.

A polytechnic is proud to be the leading supplier of high-quality fireplace heat exchanger equipment as well as having a team of experienced and enthusiastic survey consultants. Coming to a polytechnic, surely all problems are solved thoroughly and quickly.

What is a plate heat exchanger?

This is a type of device that uses metal plates to transfer heat between two liquids. In engineering, plate fireplace heat exchangers are widely common because of the large liquid contact surface. This facilitates heat transfer and increases the rate of temperature change.

The concept behind plate heat exchangers is the use of pipes or other containment vessels. In most cases, the exchanger consists of a spool containing one liquid that passes through a chamber containing another liquid.

Summary

The walls of the pipe are usually made of metal or a substance with high thermal conductivity, to facilitate exchange, while the outer casing of the larger cavity is made of plastic or coated with insulation, to prevent heat exit from the exchanger.