Rules to be followed for heat exchanger plate

The uses and applications of heat exchanger plate are more than varied. They install on technological lines, in the domestic sector, and in hot water supply and heating systems, and all because, with maximum efficiency, these devices are small and easy to maintain.

Today the experts will talk about the conditions that must be observed when installing plate heat exchangers. Let’s get started and dive deeper in more details.

Three connection schemes for heat plates

When choosing a particular connection scheme, the following factors are important. The output parameters of the heating devices and the entire system as a whole are to be taken into account.

1-Parallel single-stage

Here heat exchanger plate is important the most elementary since it makes it possible to integrate the heat exchanger quickly. However, it is only suitable for simple systems with one household appliance.

Advantages of parallel single stage

- First, and foremost these connections are low cost and have compactness

- Thus, it results in saving useful space

- Moreover, this factor is especially important in view of the scope of use

Disadvantages of parallel single stage

- Among the disadvantages is the lack of the ability to heat cold water

- Also, it is characterized by an increased flow rate of the coolant

- Hence, it requires the installation of pipes of a larger diameter than in standard solutions.

2-Mixed two-stage

Here, heat exchanger plate is an excellent solution for almost any kind of heating systems. It is including autonomous type. Moreover, it is suitable for public buildings, including office, shopping centers, educational, social. Given ahead are the advantages and disadvantages of this stage.

Advantages of mixed two-stage

- Inlet stream heats by heat from the return stroke

- Thus, the savings in the coolant in this system is about 40%.

Disadvantages of mixed two-stage

- High financial costs, since at least two heat exchangers install

- Also, the requirements - in this case, they apply very high

- Both to the accuracy of the installation

- The previous calculations

3-Sequential two-stage

Most often this heat exchanger plate is common in large-scale systems with several heat exchangers and many plumbing and radiators. This works best for working on larger scale. Given ahead are some of the advantages and disadvantages of sequential two stage.

Advantages of Sequential two-stage

- This is a rather obvious savings in comparison with a parallel and mixed two-stage scheme

- Also, their percentages are 60% and 25%, respectively.

Disadvantages of Sequential two-stage

- The system install on technological lines, but at the same time it is rarely common today

- Since there is a risk of overheating of all integrated equipment

- Additionally, it is almost impossible to fully automate the management of such a system

- And installation is more than laborious.

How to install a plate heat exchanger correctly

6 basic conditions for success in heat exchanger plate are:

- Consideration of the format of use

- Correct technical design

- Installation for further maintenance

- Choosing the optimal and most economical scheme

- Using the services of professionals specifically in heat exchange equipment

- Mandatory commissioning works

Heat exchanger water-water: design differences and purpose

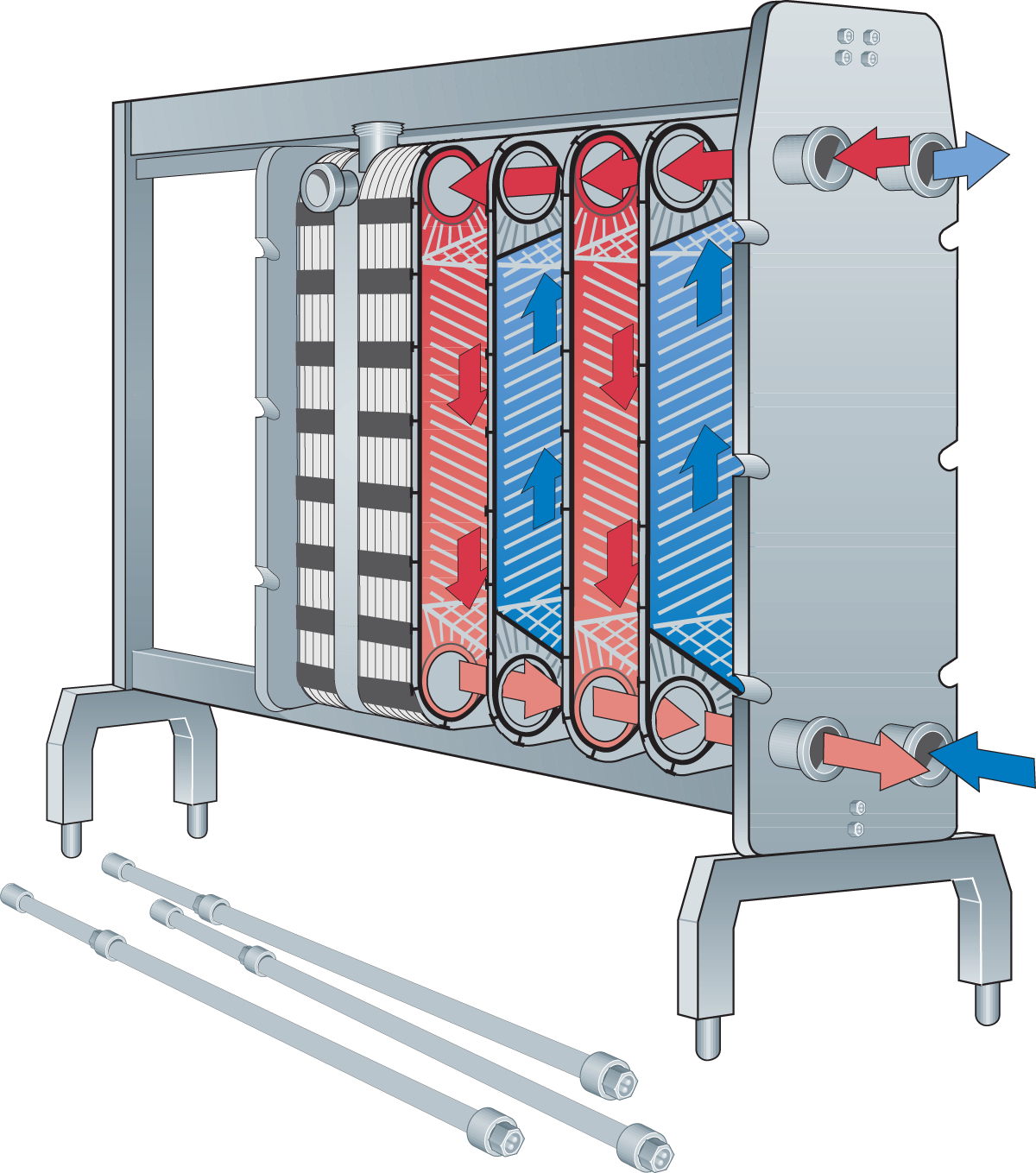

Water supply, heating, as well as several production processes involve the installation of water-to-water heat exchanger plate - plate or shell-and-tube type. What is the difference between this design of the device? Water-water in this case is a characteristic of the media.

This is the basis for choosing a device of one type or another. And this variety is one of the most popular and versatile. Such a heat exchanger can be common in the pharmaceutical industry, in the oil and gas industry, in the chemical and mining and processing industries, as well as in air conditioning, water supply and heating.

Moreover, such a heat exchanger can be common both for cooling and heating the working fluid. Suppose that in the production of food products, either hot water (industrial) or steam is more often the medium that transmits the temperature, and the food product itself, which requires heating, goes through the second circuit.

Classification and varieties of exchanger plate

The materials for heat exchanger plate are copper, titanium, stainless and ordinary steel. By the type of assembly, they are collapsible and non-collapsible.

The key difference in classification is the construction:

- Submersible

- Pipe in pipe

- Lamellar

- Irrigation

- Shell and tube

How water is heated in a heat exchanger depends on the design features of the equipment. In general, it is quite the same type: a high-temperature working fluid passes through one of the circuits, a cold fluid passes through the second, which serves as a cooler or must be cooled.

Heat transfer carries out through the walls of the pipes or through the plates (high, due to the good thermal conductivity of materials). Also, this parameter for heat exchanger plate depends on the speed with which the functional medium moves, on the temperature difference between the flows.

Purpose of the water-water heat exchanger

The main tasks that the installation of such a device solves are three:

- Increasing the temperature of the water of pool

we are talking about both large-scale and small private formats, in which water-water is considered the most practical and profitable solution.

- Heating of sanitary water

High-power devices are common either in boilers with two circuits, or for heating water in the conditions of the main unit in multi-story buildings.

- Use in heating systems.

Heat exchanger plate is easy to install both in systems with solid fuel boilers and a buffer tank, as well as operate from other sources (for example, a solar collector or a heat pump).

What are the advantages of a water-to-water heat exchanger?

First, this is long-term operation, reliability, and performance since such devices operate in rather mild conditions and do not encounter aggressive media. For industrial enterprises, communal services, the most convenient are plate-type heat exchangers of a collapsible type.

They involve simple maintenance, are easy to clean, and in case of damage to any of the plates, it, as an element, can be replaced, as well as the gasket (which wears out over time). When it comes to small systems, it is rational to use brazed types of heat exchanger plate

Summary

Fast and hassle-free installation in any system, affordable cost is the main advantages. But the high flow capacity and low hydraulic resistance of shell-and-tube types make them an excellent solution for swimming pools.