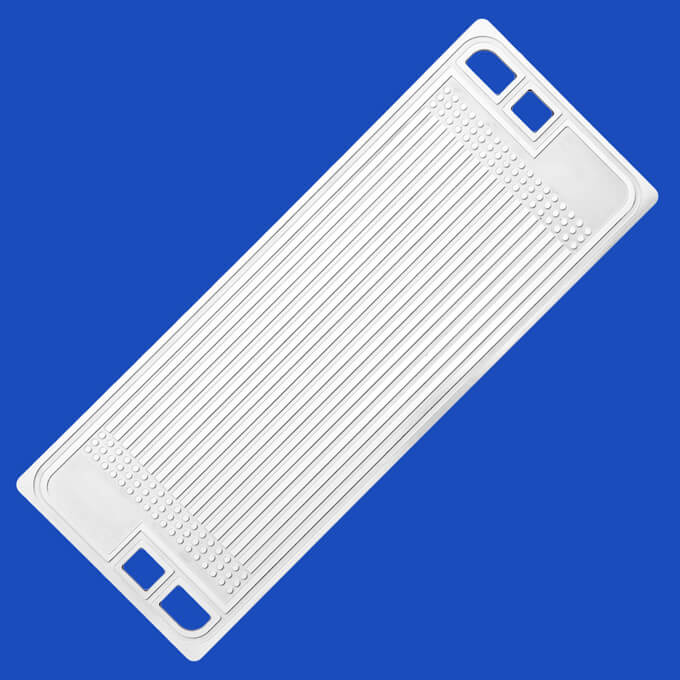

Introduction of Micro channel perforated flow plate

In human economic activity, it is almost always required to organize the process of heat exchange between Micro channel perforated flow plate, for example, to heat a liquid or, conversely, to cool it.

For such purposes, it is enough for a person to use micro channel perforated flow plate in their activities. These are technical devices that carry out the process of heat exchange between several media.

Although flow plates have a single primary purpose, they can still differ in their structure and in numerous other parameters. That is why the question arises: what equipment to choose for specific conditions?

The classification of devices with plates represent as follows:

Disassembled devices. These are, as a rule, devices with smaller dimensions, but high efficiency, which are already well established. It is this species that comes by a simple installation process and a fairly good efficiency in its work.

It is thanks to its features that the Micro channel perforated flow plate easy to clean, and the performance and efficiency easy to increase by installing an additional number of plates.

Apparatuses made using soldering technologies. Plates for this device are made of high strength steel. To increase the strength of the plates themselves, they solder during production, making it possible to use equipment in different pressure ranges and temperature conditions. But the environments should be non-aggressive and clean.

Equipment models with a semi-collapsible structure.

The design is represented by modules, which consist of several classic plates. In this case, maximum reliability and good wear resistance of the technical apparatus is important, since there are no gaskets and rubber seals.

Lamellar, with welded elements in the device. They have a long service life; they are common in cases when it is impossible to use devices of a collapsible design.

Among the variety of heat exchange equipment, one more type easy to separate - not Micro channel perforated flow plate. Shown here are shell and tube models and spiral models.

Micro channel perforated flow plate consists of several tubes

In a shell-and-tube apparatus, the heat exchange surface consists of several tubes that cover with a shell. Heat exchange carries out here due to the surface of these pipes.

The spiral Micro channel perforated flow plate represents by metal sheets that roll up in the form of spirals. Here, 2 thin metal sheets serve as the heat exchange surface. The advantages of this type of equipment are compactness and low hydraulic resistance.

However, it can only be common if the coolant pressure is low. In addition, this type comes by the complexity of the repair.

Most important criteria Micro channel perforated flow plate

Summing up a small summary, we can conclude that there are quite a few types of heat exchange equipment. The most important criteria when choosing heat exchange equipment are the conditions for its use. This is both the temperature regime and the magnitude of the pressure.

How to choose Micro channel perforated flow plate

A flow plate is a device that transfers heat energy from one medium to another without mixing them. Accordingly, the selection of a plate flow plate for hot water supply carries out depending on the purpose, the required temperature values, the type of medium, and the conditions of use.

After determining the listed criteria, an accurate calculation of the parameters of the flow plate carries out.

Medium type of Micro channel perforated flow plate

The flow plate can work with different substances: gas, oil, water, steam. Their physical and chemical properties will differ, so they need to determine in advance before choosing a Micro channel perforated flow plate.

Aggressive substances require high strength characteristics of the device. If a non-standard medium is common, the values of heat capacity, viscosity, thermal conductivity are required.

Temperature of Micro Channel Flow Plate

The main function of the flow plate is to change the temperature characteristics of the medium. Therefore, the values of the temperature of the heating medium at the inlet and outlet will differ.

ALLOWABLE PRESSURE LOSSES OF THE HEATED AND COOLED SIDES

The working medium, when passing through the flow plate, loses part of the pressure. This is due to design features. In most processors, pressure is an extremely important characteristic, which is why it is necessary to accurately calculate the allowable losses before choosing a device.

So, for example, when choosing a flow plate for a house, you need to take into account that insufficient pressure will not allow water to rise to the upper floors.

MAXIMUM OPERATING TEMPERATURE AND PRESSURE

The flow plate must be made of materials that are resistant to specific temperatures and pressures. Therefore, the selection of a flow plate for different conditions will differ.

HEAT LOAD

A flow plate transfers part of the energy from one medium to another. The transfer rate, the permissible volume of the medium, the desired temperature regime will affect the size of the Micro channel perforated flow plate.

CALCULATION OF CHARACTERISTICS OF FLOW PLATE

When all the technical operating conditions determine, they proceed to the calculation of characteristics that will help to select a flow plate for specific conditions. The following types of calculations carry out:

- Thermal;

- Mechanical;

- Calculation of temperature stresses;

- Composite;

- Hydraulic;

- Constructive calculation;

- Strength;

Thermal calculation is the main parameter that necessary calculated before choosing a flow plate for heating.

It is for the following purposes:

- Determination of heat transfer efficiency;

- Willpower of the area of heat exchange surfaces;

- Purpose of the final temperature;

- Mass calculation of the coolant;

- Calculation of other operating parameters of the installation.

Parts of the device easy to subject to various mechanical loads, including tension and compression, torsion, shear, bending, vibration.

Conclusion

Thermal stress is a parameter associated with linear and volumetric changes in the geometric dimensions of a structure, which come by thermal expansion. It considers the data obtained from the calculation of thermal characteristics.

Moreover, for a proper result, the need of professional flow plate manufacturer is compulsory.