Micro channel perforated plate types

Micro channel perforated plate for transferring heat between a heated and cold environment divide into the following types, depending on the pattern of movement of heat carriers:

Single-pass lamellar apparatuses, in which the medium moves constantly along the same trajectory. In this case, the coolant passes along the entire length of the device. Even in such devices, the media always move in opposite directions. This is their main distinguishing feature.

Multi-way channel perforated plate

Multi-way micro channel perforated plate devices, important for use on those objects where it requires achieving a slight temperature difference between heating and heated liquid. In these devices, the branch pipes locate not only at the front on the fixed part, but also at the end on the pressure plate.

In devices of this type, the flows of media can change the direction of movement. This can happen in several or exclusively in one turn. Multi-pass heat transfer devices come with one inlet and one outlet.

Multi-circuit micro channel perforated plate

Multi-circuit lamellar devices with independent circuits in the amount of 2 pieces. They locate on one side. Such devices are common in cases where it is necessary to create two-stage conditions for cooling or heating the coolant. Also, these heat exchangers allow you to effectively control the heat output.

However, the classification of micro channel perforated plate heat exchangers does not end there. They further subdivide depending on the ease of access to the devices, since their surfaces must not only fair mechanically, but also simply inspected.

Manufacturers create three types of plate-type heat exchangers:

Collapsible devices with the smallest possible dimensions. These devices are very easy to maintain. Their corrugated plates and all channels easy to clean without difficulty if necessary. Moreover, the design of such heat exchangers allows you to change the number and even the type of corrugated plates.

As a result, it becomes possible to reduce or increase the power of a single device. If a coolant leak occurs, then in this case it is not difficult to fix the breakdown either, since you can quickly replace the sealing element or plate.

Semi-dismountable micro channel perforated plate

Semi-welded devices, which also include semi-dismountable devices. Such heat exchangers consist of several modules come by welding. Each of them includes two corrugated micro channel perforated plate. Laser machines are common to weld them together.

A single package assembles from these modules. For this, end plates and bolts are common with which they are pulled together. These heat exchangers are common in cases where a heat transfer medium has an increased pressure or temperature. Still devices of this type are common for heating or cooling hazardous environments.

Non-dismountable micro channel perforated plate

Non-dismountable devices, which are heat exchangers, come by soldering. They consist of a certain number of corrugated stainless steel plates. These elements connet to each other by soldering. This process is carried out in a vacuum.

In this case, nickel or copper solder is also common. Such micro channel perforated plate come by increased reliability, small dimensions and easy installation. Non-dismountable devices can independently clean their channels, since there is a high turbulence in the flow of the medium in them.

In addition, they provide good economic benefits. These devices are common in heat supply, where they are common to heat water.

Minimum number of plates in micro channel perforated plate

All the above plate-type heat exchangers come of sheet metal. The minimum number of micro channel perforated plate in one apparatus is usually 7 pieces. Their maximum number of the any, since there is practically no limit to anything. Moreover, the highest temperature of the heating medium does not exceed 150 degrees.

At the same time, the maximum pressure is 9.8 bar. The amount of coolant that passes through the heat exchanger is influenced by its dimensions.

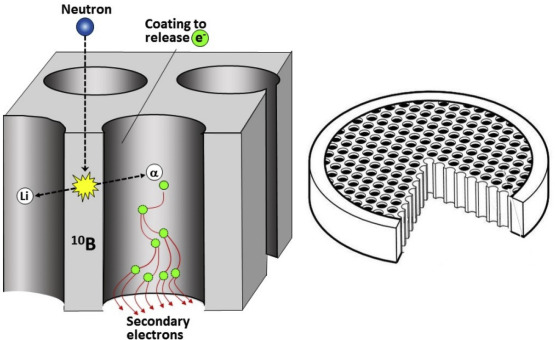

The principle of operation of the plate heat exchanger

On a fixed plate common to support the device, there is a branch pipe through which the medium enters the device. It will subsequently heat to the desired temperature. After that, the medium moves to the longitudinal collector. For this, the heat exchanger has a corner opening.

Due to the presence of a collector, the medium moves to the last micro channel perforated plate. At the same time, it evenly distribute absolutely along all the channels located between the corrugated plates. In addition, seals, which come in a special arrangement, facilitate the connection of the interplate channels and the corner manifold.

Elements of the heat exchanger

When the heated medium moves along the interplate channels, it passes along the corrugated surfaces of the flat elements of the heat exchanger. They, in turn, are heated from the reverse side by another coolant that has a certain temperature in each specific situation.

After that, the medium, which gets heat, enters the lower collector. Then it leaves the heat exchanger through the corresponding branch pipe.

Heating medium micro channel perforated plate

The heating medium of micro channel perforated plate enters the apparatus through a branch pipe intended for supplying a heated liquid.

Its movement is performed towards the medium to heat. Due to the presence of the lower collector, the heating coolant distribute, which then moves through the channels.

The channels intended for the heated and heating medium alternate. For this reason, the device, which has the simplest design, must consist of at least 3 micro channel perforated plate. It is this number of flat elements of the heat exchanger that forms two channels. One of them intends for a heating medium, and the second is for a heated medium.

Conclusion micro channel perforated plate

The fluid moving through the channels performs tortuous movements in three directions. Due to this, it’s tribalization forms. In this case, the hydraulic resistance not only at the outlet, but also at the inlet to the channel decreases when the coolant passes through the corner holes.

Due to this, absolutely the entire area of the micro channel perforated plate elements of the device is common efficiently.