Flow plate or plate: which is the best cooling?

When looking for a refrigerated water purifier, it is natural to doubt between micro channel porous flow plate or electronic board. After all, these are the two existing refrigeration systems on the market, with different technologies.

Currently, the offer of chilled water purifiers is vast, and it difficult to know which is the best option. So, to evaluate with good criteria, it is important that the consumer understands about some matters.

Differences between filtration technologies

Differences between filtration technologies, lifetime and refrigeration systems are key. Likewise, it is necessary to know which certifications the product must have and to understand more about its efficiency.

If cold water is essential for you, follow the text! Next, we'll explain the differences between the systems and buy which one is better: flow plate or board?

Water purifier with micro channel porous flow plate

This is a very familiar system to all of us. Do you know why? Because the micro channel porous flow plate refrigeration is the same system that works in your refrigerator. As the name already indicates, inside the two devices, there are several compressed gases.

First, don't worry about gases: they don't harm your health or the environment. The models currently sold are ecological as they no longer use CFC as a refrigerant gas. Flow plate or electronic board systems also require electrical energy. Once plugged in, the flow plate starts to work.

In short, the water-cooling process takes place with the compression of gases and without heat exchange. If you want to understand more details about this process, find out how it works.

Electronic board cooled micro channel porous flow plate

This system, in turn, is often found in electronic equipment. It operates through a board, which controls a set of thermal chips.

The so-called thermoelectric chips are the conductors of this system that operates with micro channel porous flow plate. When subjected to an electrical voltage, they heat up.

In this way, the internal part cools and the external surface heats up, later dissipating this heat through an adequate system.

Now the difference in operation is clear. But, how to choose between micro channel porous flow plate or electronic board?

Flow plate or electronic board? Advantages and disadvantages

Do you want to know which system is right for you or your company? Discover the main differences between the two systems, as well as the strengths and weaknesses of each.

Water volume, cooling speed and electricity consumption are the main criteria. Check out:

Choosing between a flow plate or an electronic board

Depending on the flow of people in your environment, choosing between a flow micro channel porous flow plate or an electronic board decisive. Due to the difference in cooling capacity, one is more suitable for large flows than the other.

The flow plate purifier, like the Summer HF, freezes more water and faster. So, for businesses, offices, schools, companies, etc., it is the best option.

More resistant to voltage fluctuations, lasts longer and leaves the water cooler. On the other hand, the electronic board consumes less energy and can serve a small family or single people well.

After all, which is better: flow plate or plate?

There is no right answer to this question. This will vary depending on your need, your finances, and the way you want to drink water.

To have colder water and in greater quantities, it is certainly worth investing in a purifier with a flow micro channel porous flow plate. It is even more advantageous when we think about commercial environments or families with more than 3 people. Despite costing more, it is also more resistant and robust.

Prefer a purifier with a flow plate

If you consume little chilled water and have up to 2 people in your home, a purifier with a board can do the trick. And now, do you know if you prefer a purifier with a flow plate or an electronic board? Discover our refrigerated line and find the ideal model for

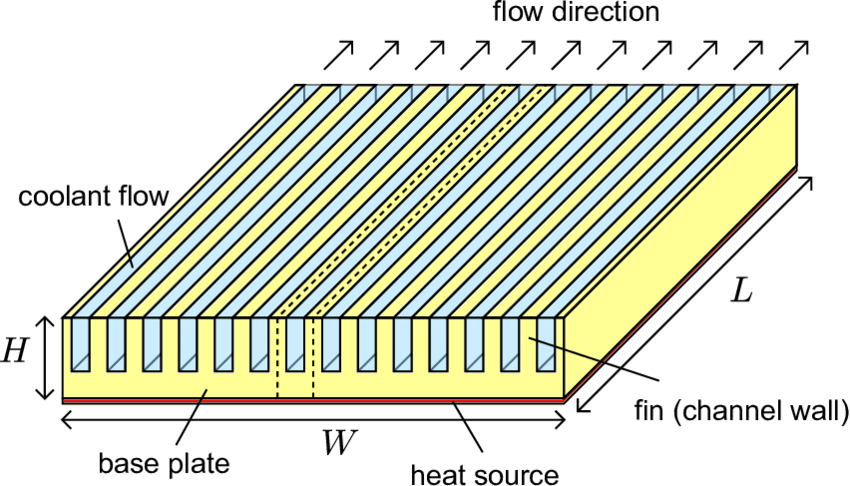

These elements are connected to each other. In this case, their fastening is carried out with a rotation of 180 degrees relative to each other. In addition to the plate package.

Types of heat exchanger also includes:

- movable plate;

- a fixed plate on which the branch pipes for connecting pipelines are located;

- fastening elements, due to which the contraction of 2 micro channel porous flow platetakes place and a frame is created;

- two guides (upper and lower) in the form of a round bar.

Such a well-thought-out arrangement of the device makes it possible to create devices with compact dimensions.

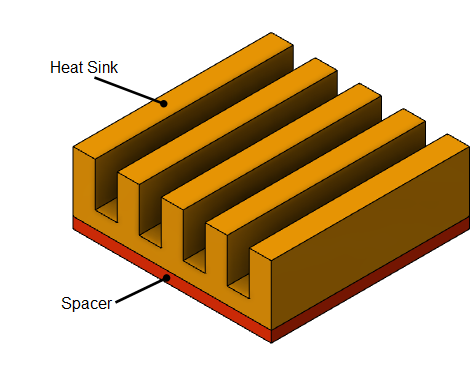

micro channel porous flow plate made with copper and stainless steel

The frame of the plate heat exchanger serves to fix the plates, which are made not only of stainless steel, but also of copper or graphite. Because the surface of the device is peculiar, it creates a rather strong turbulence for media common for heat transfer and moving through pipes.

After installing the corrugated plates in their places, two sealed systems are formed, completely isolated from each other. It is along them that the cold and hot environment moves. Thanks to this design, heat exchange takes place.

very important elements micro channel porous flow plate

A package is assembled from the corrugated plates. Moreover, they are located crosswise. Their placement allows you to create a rigid structure. All corrugated micro channel porous flow plate is fitted with gaskets to seal the joints. These are very important elements that ensure a good tightness of the device, especially in working order.

The gaskets allow the coolants to flow smoothly in opposite directions through the pipes. They have a special configuration. Due to this design feature of the sealing elements, mixing of cold and hot media is not allowed.

High heat required for micro channel porous flow plate

A high require heat transfer coefficient is easy to achieve if the heat exchanger is size correctly in accordance with the given volume of flowing medium. Moreover, in such a device there is an increased turbulence of the heat carrier.

The corrugated micro channel porous flow plate is a surface type device. A heated and heating medium moves along it. Between them, heat is transfer through the metal wall. It was she who received the name - the heat exchange surface. The main elements of such a heat exchanger are wavy plates.

Conclusion

Plate heat exchangers are common as heating or cooling devices. They are common in various technological processes, as well as in the oil, gas industry and many other industries. The photo below shows a micro channel porous flow plate heat exchanger in an individual heating station of an apartment building.