There are two main types of heat exchangers heated by steam, micro channel printed circuit heat exchanger has most uses solutions in the sector, precisely because of its sterility and ease of adjustment, in addition to its high calorific value.

These two types of heat exchangers use for heating applications and processes that use steam are:

What is Tube heat exchanger?

Traditionally, the tube heat exchanger has been uses for many heating and processing applications using steam across a wide spectrum of industries. It rugs and often "over-design" for the job.

It tends to have an inherently high mass and high thermal hysteresis, which can make handling some critical applications difficult.

Tube heat exchangers are often very large at initial installation, mainly due to the large fouling factors apply during the calculation. In micro channel printed circuit heat exchanger in which steam passes through tubes, the tubes tend to have a low transfer rate.

Fatigue of metals in the tube walls

This low speed also tends not to clean the tube surfaces. Therefore, generally high fouling factors apply at the design stage, which will result in oversizing.

Due to this oversizing, the actual steam pressure after installation is often lower than expected. If does not anticipate, the steam trap may not be the correct size and the steam tubes may flood with condensate. It causes erratic control and poor performance.

Plate heat exchangers: a useful alternative

Micro channel printed circuit heat exchanger is relatively small and light. They are extremely quick to respond to changing heat loads. When they well design, they tend not to get dirty. But if they do, they can easily dismantle, clean, and put back into service.

Compared to tube heat exchangers, they can operate at lower pressures for the same service. Due to their high heat transfer characteristics and less need for oversizing. They are even smaller and cheaper than a heat exchanger of comparable tubes.

Economically suited micro channel printed circuit heat exchanger

Therefore, plate heat exchangers (when properly designed to work with steam) are more economically suited to high pressure drops through control valves than their tube counterparts. This can give us the advantage of using smaller and less expensive control valves. It minimizes the cost of the heat exchanger itself.

In general, it is best to design the system. The plate heat exchanger operates at a critical pressure drop (or at the highest possible pressure drop) across the control valve at full load.

Doubts about printed circuit heat exchanger

It should note that not all plate micro channel printed circuit heat exchanger is suitable for working with steam. It's all too easy to buy a heat exchanger design to work with liquids and mistakenly assume. It will work perfectly when heated with steam.

Periodic maintenance of heat exchangers

The importance of heat exchangers in various industrial processes is already popular. However, even with all the benefits of this equipment. It is difficult for some to recognize the need for periodic maintenance of heat exchangers.

After all, considering all the complexity of an industrial machine, sometimes it doesn't even cross our minds that only one component of micro channel printed circuit heat exchanger. It needs so much attention.

With that in mind, which is always your partner for your equipment to work with maximum efficiency. We have prepared a guide with the benefits of maintaining heat exchangers.

Save money on the maintenance of heat exchangers

The first benefit of this type of maintenance is cost savings. To understand how this happens, it's as if we were doing the overhaul on a car. Changing the oil is cheaper than rebuilding the engine. Likewise, checking the quality of the equipment's heat exchanger plates helps keep production efficient, and is much cheaper than a total equipment breakdown.

Nothing is more expensive than a stopped machine

Preventive maintenance is plan maintenance. Therefore, micro channel printed circuit heat exchanger is made at the best time for the industry. Thus, avoiding a production line stopped due to urgency in a period of great demand.

Extend the life of heat exchangers

The best way to extend the time of use of an equipment is through its good use and periodic maintenance. And in this context, when we maintain heat exchangers, we are able to maintain their useful life longer, reducing costs and increasing the industry's productive efficiency.

The maintenance of micro channel printed circuit heat exchanger.

When maintaining the heat exchangers, the entire equipment system also analyzes. In this context, it is important to have a partner who knows the entire machine system, to be sure how to identify these problems. This is an excellent way to ensure that the equipment does not stop.

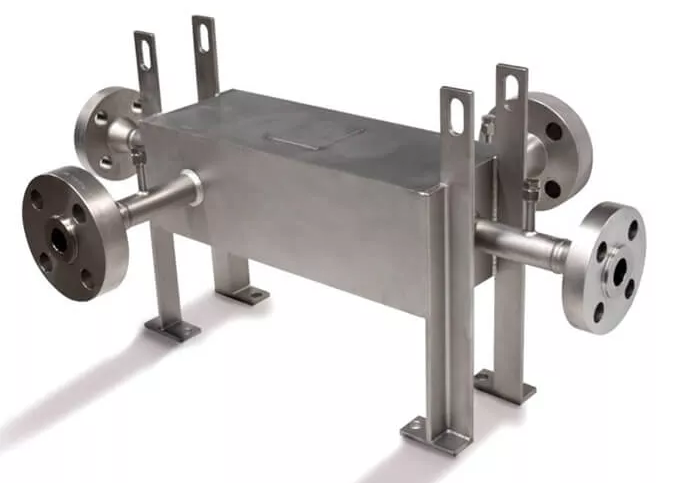

Plate heat exchangers have uses in many fields of industry. The plate heat exchanger consists of a series of plates place parallel to each other. It allows a series of channels to form to allow fluid to flow between them.

Inlet and outlet holes allow hot and cold fluids

The space between two adjacent plates of micro channel printed circuit heat exchanger forms a channel through which fluid flows. Inlet and outlet holes in the corners of the plate allow hot and cold fluids to pass through alternate channels in the exchanger. The plate is always in contact with hot fluid on one side and cold fluid on the other.

The size of the boards can vary from a few square centimeters (100 mm x 300 mm side) to 2 or 3 square meters (1000 mm x 2500 mm side). The number of plates in a single exchanger varies from ten to several hundred and can reach a surface exchange area of up to thousands of square meters.

The heat exchange provides mechanical rigidity to the exchanger

Generally, these plates of micro channel printed circuit heat exchanger are corrugated in order to increase the turbulence. The heat exchange surface and provide mechanical rigidity to the exchanger. Corrugation obtains by cold forging metal sheets with thicknesses from 0.3 mm to 1 mm.

The most commonly uses materials for the plates are stainless steel (AISI 304, 316), titanium and aluminum. Corrugation in the plates forces the fluid in a tortuous path, establishing a gap between two adjacent plates b, from 1 to 5 millimeters.

Fluids can cross the channels in series (a less common solution) or in parallel in countercurrent or current configurations.

The serial configuration and the parallel configuration

The serial configuration of micro channel printed circuit heat exchanger is uses when there is a small flow rate for each fluid but high heat jump. The biggest problem is with a high pressure drop and an imperfect countercurrent.

The parallel configuration with countercurrent channels is uses for high flow rates with moderate temperature drops and is the most widely uses.