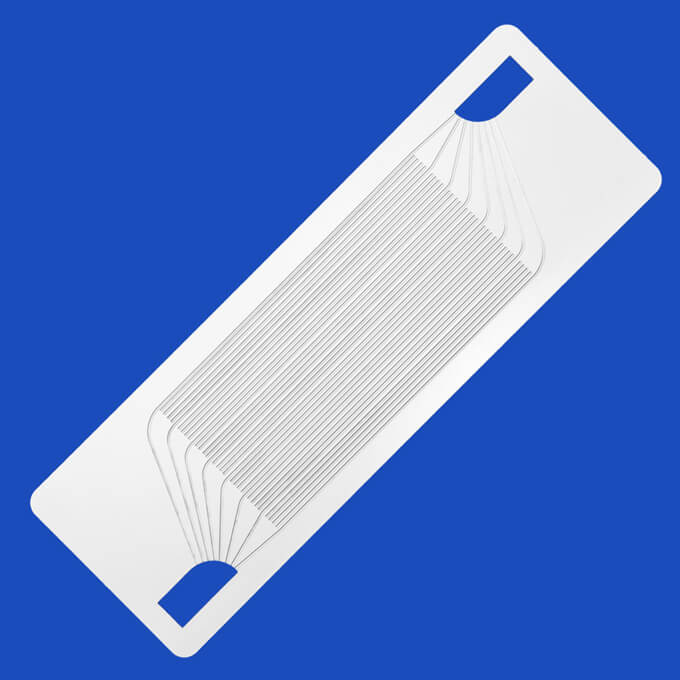

Introduction of Micro-fluid channel plate

The heat exchange process in shell and micro-fluid channel plate for the pool is carried out through the surface of the metal tubes. The hot liquid of the heating system enters the Micro-fluid channel plate side of the heat exchange tank and contacts the surface of the tubes, through the inner channels of which the heated liquid flows from the pool.

The hot coolant gives off thermal energy to the metal of the tubes, which transfers it to cool water. The more tubes are installed in the body of the channel plates, the higher its capacity.

Advantages of Micro-fluid channel plate:

- simplicity of design;

- Also, large heat exchange area;

- Moreover, resistance to water shocks;

- Furthermore, the ability to carry out high-quality heat exchange between the coolant and the heated liquid with a slight temperature difference;

- In addition, low demands on the quality of heated water purification.

Disadvantages of Micro-fluid channel plate:

- lower (than that of plate channel plates) efficiency;

- Also, lack of the ability to increase power;

- Moreover, lack of access to tubular channels when checking for cleanliness during maintenance;

- Furthermore, large dimensions and metal consumption of the structure, requiring the preparation of a special installation foundation;

- In addition, the need for thermal insulation of the Micro-fluid channel platebody;

- Also, the inability to detect fluid leakage from the heat exchange tubes without disassembling the heat exchange unit;

- Moreover, replacement of the failed channel plates tubes - only during the overhaul of the channel plates.

As easy to see from the above comparison, plate channel platess are easier to maintain, have higher efficiency and are small. However, pool owners are trying to purchase exactly shell and tube channel platess, since they:

- have a larger heat transfer area;

- Also, do not create hydraulic hindrances to the passage of the heated liquid;

- Moreover, less clogging during operation.

What materials we use in micro fluid channel plate?

For swimming pools full with fresh water, Micro-fluid channel plate are made of stainless steel. Stainless steel does not emit iron ions and therefore does not darken the pool water. It easily withstands thermal shocks, and, if necessary, is easy repair.

The chemical composition of the stainless material is quite inert, so a channel plates made of anti-corrosion steel will last at least ten years before overhaul. And the main advantage of the material is its relatively low cost compared to other (not subject to corrosive destruction) structural materials.

If the pool tank is full with seawater, the stainless-steel channel plates will not last long. For such operating conditions, titanium channel plates are factory-made. Structural titanium:

- chemically passive (practically does not oxidize and does not react with chlorine, fluorine, various salts);

- has a high temperature resistance;

- lightweight and durable.

The performance characteristics of titanium fully offset its significant cost.

Channel Micro-fluid channel plate

When choosing a Micro-fluid channel plate for a pool, you should pay attention to four indicators:

- Maximum operating temperature. Indicates with what maximum temperature of the heating medium the channel plates can work.

- Material of channel plates tubes and plates. For fresh water, stainless steel is chosen, for tanks with sea water - titanium.

- Channel plates capacity.Shows how long the entire volume of the pool pump through the channel plates. According to this parameter, the performance of the circulation pumps is.

- Thermal power. The most important indicator that you need to know when choosing heat exchange equipment. If a lower power is selected, then the water in the pool will not warm up to the set temperature parameters. If the buyer purchases a channel plates with an high price capacity, then he will pay extra money that he could spend on the purchase of other equipment for the pool.

SIMPLIFIED POWER CALCULATION

For the user to be able to choose the right Micro-fluid channel plate for the pool, there is a method for a simplified calculation of the desire capacity of the channel plates. To execute it, the following parameters must be known:

- V is the volume of the pool reservoir, l;

- S is the area of the pool mirror, m2;

- Ttreb is the compulsory water temperature in the pool, ° С;

- Тnabr is the temperature of the water just drawn into the pool reservoir from the water supply, ° С;

- t is the time of water heating from the initial to the final temperature (usually 2-3 days), h;

- С - specific heat of water, always 1.16 W / kg * K;

- q is the heat leakage from the pool due to surface evaporation of water, W / m2.

Swimming pool heat loss regulation (q):

- set outdoors - 1000 W / m2;

- located in the building - 520 W / m2;

- semi-shut tanks - 620 W / m2.

Knowing all of the above values, it is easy to determine the power of the channel plates by the formula:

P = V * C * (Treb - Tnabr) * 1 / t + q * S,

where P is the required Micro-fluid channel plate power, W.

Outdoor pool designed for sports swimming:

- depth 2 m;

- length 10 m;

- width 5 m.

It was filled with tap water, which has a temperature of 12 ° C, and now it takes three days to warm up the water in the pool bowl to 26 ° C.

Let's start calculating:

- Determine the volume of the pool in liters: V = 5 * 10 * 2 * 1000 = 100,000 liters.

- Determine the area of the pool in m2: S = 5 * 10 = 50 m2.

- Determine the heating time and select the heat loss coefficient: t = 3 * 24 = 72 hours (q = 1000 W / m2, since the pool is located outside).

- The required power: P = 100,000 * 1.16 * (26-12) * 1/72 + 1000 * 50 = 72,556 W.

Basic Rules to operate fluid channel plate

For pool Micro-fluid channel plate to serve for a long time, equipment manufacturers recommend:

Measure the level of hydrogen activity of the water in the pool tank daily. The pH should be in the range of 7.4-7.6 units. If the pH rises above 7.8 or falls below 7.2, the heat transfer tubes and plates begin to deteriorate. If necessary, the characteristics of the aquatic environment are change.

Must clean regular plate surface

Regularly clean the pool surface from leaves, grass and other rotting debris. The decay process raises the pH, which affects the durability of metal equipment.

When adding chlorine to the pool tank, do not allow the entire volume of the drug is add to the water in one place. With such an application, the chemical reagent evenly in the liquid, and therefore an area of high acidity will arise. When such water passes through the Micro-fluid channel plate, the metal tubes is damage.

Conclusion

The main malfunction of any channel plates (both shell and tube and plate) is the formation of scale on the surface of the heat exchange plates and tubes. Because of this, the performance of channel plates decreases, since the thermal conductivity of the water stone is ten times lower than the thermal conductivity of stainless steel.