What is multifluid heat exchanger?

A Multifluid heat exchanger is a device that allows the transfer of thermal energy from a fluid at a higher temperature to one at a lower temperature. Trying to be more specific we can say that it fulfills a double function:

- Modifies the thermodynamic state of a fluid current by thermal interaction with another

- It allows the transfer of a thermal power between a solid surface and a fluid current.

It is among the most widespread and common thermodynamic components and has a wide range of applications.

Types of heat exchangers

The multifluid heat exchanger process between two fluids is easy to carry out in various ways and there are just as many types of SDC that is easy to define on the basis of various factors:

- construction materials;

- type of fluids that evolve there;

- Thermo-fluid dynamic design.

A certainly simple way to achieve the transmission of heat between the two fluids obtains by making one fluid flow in the inner tube and the other fluid in the annular area which locates between the inner and outer tube of two coaxial pipes of multifluid heat exchanger.

This system leads to highlighting two volumes of control:

- one is characterized by the fluid evolving in the inner tube;

- The other is characterized by the fluid that evolves in the annular area between the inner and outer tube.

The Heat Exchange Process Is Simple

In essence, the heat exchange process is simple. Section by section there is always a temperature difference between the fluid at a higher temperature (hot fluid) and that at a lower temperature (cold fluid) which allows the transfer of thermal energy between the two.

A heat exchanger that operates in this way calls coaxial tubes or tube in tube

Two Possible Flow Conditions for multifluid heat exchanger

There are two possible flow conditions of this type:

- the two fluids flow in the same direction and towards ( co-current );

- The two fluids flow in the same direction but in the opposite direction (counter -current).

Although the operation is simple, as seen, this type of SDC has large dimensions and is therefore rarely common.

The shell and tube heat exchanger, on the other hand, is more common. In it, one fluid flows in the bundle of tubes and the other fluid evolves between the inner surface of the mantle and the outer surface of the tubes.

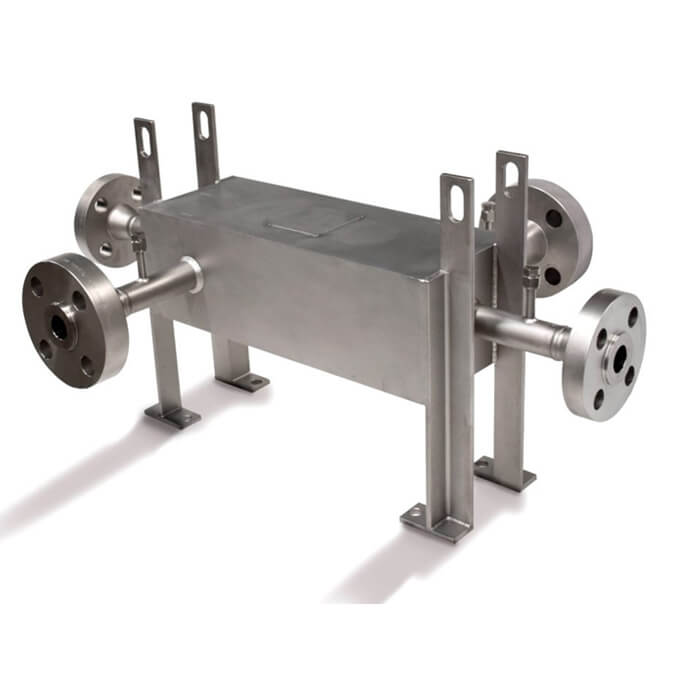

The main elements of multifluid heat exchanger

- inlet:Head not completely semicircular, but slightly elongated, which allows the fluid to be directed into the pipes, favoring a distribution as uniform as possible;

- Tubesheet: to which the head connects, and comes with holes in which the ends of the tubes of the tube bundleallocate;

- Shell:that contains the tube bundle and, often, also some diaphragms, which serve to increase the turbulence of the fluid flowing in the shell, making the transmission of heat more efficient.

It should note that the distance between the ages of two pipes call the pitch.

The most efficient utilization of shell and tube SDCs achieves when both fluids are in the liquid phase.

In fact, multifluid heat exchanger in which at least one of the two fluids are a gaseous would require high surface areas of heat exchange, as it is known that the convection coefficient of gaseous is lower (in orders of magnitude) than that of liquids.

SDC to the tube-and-shell SDC

A similar SDC to the tube-and-shell SDC is the cross-flow one. In it the two fluids evolve following directions perpendicular to each other. The fluid flowing through the pipes is unmixed.

The type of finned or compact plate heat exchangers is also different. In multifluid heat exchanger, very high values of the ratio between the heat exchange area and the volume are achieved. They form by a succession of finned plates, on whose surfaces the channels in which the hot and cold fluids evolve.

There are various configurations of finned plate SDCs. The following data shows an interchangeable plate heat exchanger:

Compact exchangers are frequently common when one or both fluids are in the gaseous state. The very high heat exchange areas per volume unit allow the transfer of acceptable thermal powers despite the modest convection coefficients of the gaseous ones.

Performance of Multifluid Heat Exchanger

In designing and evaluating the performance of an SDC, it is necessary to refer to some starting hypotheses:

- steady state conditions;

- negligence of the thermal power dispersed towards the external environment (we will therefore understand that the thermal power entirely transferred to the cold fluid);

- specific heats of the two uniform fluids;

- Uniform overall unit conductance between the two fluids.

The efficiency can assume values between 0 and 1 (the latter is a purely theoretical limit).

Ratio between the minimum and maximum heat capacities

The ratio between the total thermal conductance of the multifluid heat exchanger and the minimum hourly thermal capacity can assume values ranging from 0 to ∞, both theoretical limits. The ratio between the minimum and maximum hourly heat capacities is less than or equal to 1 and greater than or equal to 0.

If the value is zero, one of the two fluids is in phase transition. We would face with an SDC called condenser or evaporator.

Finally, we specify that the efficiency of an SDC depends on the two ratios mentioned above but also on the geometry of the exchanger itself.

A component of a thermodynamic system

In the following article we have therefore seen an overview of what a multifluid heat exchanger is, starting from its most practical definition, that is, a component of a thermodynamic system. This allows the transfer of energy in heat mode from one fluid to another.

A brief review of some types of SDC comes, trying to highlight the advantages and disadvantages of using one or the other model. Coaxial tube, tube and shell, cross flow and finned plate heat exchangers were seen.

Conclusion multifluid heat exchanger

Finally, the efficiency method exposes, which is the simplest one to evaluate the performance of an exchanger. It appeared that the efficiency of a multifluid heat exchanger depends on various specific parameters. This comes to the more usual factors such as the geometry of the exchanger.