Free-Flow - this is the name given to heat exchange equipment with the so-called free flow. Main purpose of straight and zigzag channel flow plate is to cool and heat media that contain various inclusions (crystals, fibers, pulp).

Moreover, it also includes media with high viscosity. More recently, expensive spiral types of heat exchangers have been common to carry out such a process.

In what area is straight and zigzag channel flow plate common?

The main areas of application of straight and zigzag channel flow plate are in the production of paper and pulp. Also, the recuperative heat exchanger is widely common in industrial areas. Furthermore, these are the circulation of liquid media.

These are viscous media, liquids with crystal-like inclusions. The equipment is also common in the oil industry (for auxiliary and main technological processes, as well as oil heating), and in the food industry (for heating juice, mash, grain wort, cooling tomato and apple puree, juices with pulp, etc.).

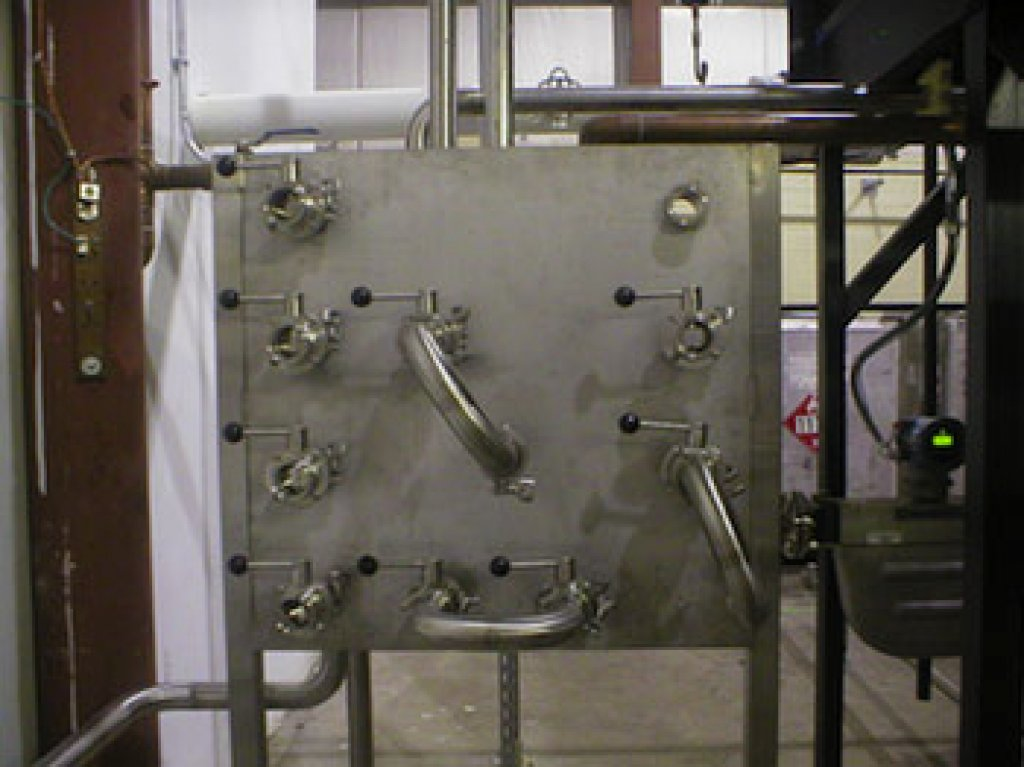

Characteristics of heat exchanger design

In this device - a recuperative heat exchanger with such characteristic plates - the design is notable for its open channels. What is the difference from traditional models? The fact that the corrugations are U-shaped here, and in the usual - "herringbone".

The seals of straight and zigzag channel flow plate with a wide bore are high and wide.

Significance and working of free flow

if one of the channel blocks becomes clogged, the heat exchanger does not stop its work.

In this case, the plates are fastened one after the other (sequential type of fastening), and given the presence of a corrugated surface. Even if the flow rate in straight and zigzag channel flow plate is minimal, a high head comes by 100%. Also, this kind of design reduces the pressure drops that can occur in the body of the heat exchanger.

Wide-channel plate heat exchanger

The wide-channel plate heat exchanger is good to manufacture considering the special design of the device. Similarly, it makes it possible to carry out preventive, and repair, and maintenance activities as needed, without stopping the operation of the equipment.

What technical features are typical for the equipment?

It is not a fundamentally different, but still a different type of device with characteristic parameters. Among them:

- First and foremost; lack of contact with other metals

- Second, No frozen (dead) zones in the plate

- Moreover, almost maximum (higher than in other types) heat transfer coefficient

- Straight and zigzag channel flow plateallows you to easily remove the device

- Furthermore, easy maintenance (no need to disassemble the device for cleaning)

- Lastly, compactness - They require several times less installation space than tubular and spiral

Installation of a heat meter

Let’s now discuss important points and principles on heat meter. Moreover, paying utilities for heating according to the norms has long been a losing option. With a frankly underestimated temperature (in the room it may not even reach 18-19 degrees), the cost is as per standard 22.

The way out of this situation will be a heat meter - a device that will allow residents to pay exactly that part of the energy and heat. Straight and zigzag channel flow plates assist this by graphing results for further improvements.

About the equipment and how it works

A heat meter is a multi-component unit that measures and counts the amount of energy common for heating.

Calculations of flow plate

Moreover, the calculation involves temperature sensors and a flow meter.

Important considerations for flow plate

The inaccuracy of indicators of straight and zigzag channel flow plates is easy to affect by sensor errors (no more than 3 degrees) comes with data rounding, as well as incorrect operation of the indicator that calculates the volume. Similarly, in the event of a malfunction, the device notifies about them on the display.

3 types of heat meters: description and technical differences

Despite a similar task performed, there are three types of equipment, each of which is fundamentally different from analogues in terms of the principle of operation:

1-Electromagnetic

The most popular and demanded format, it comes by stable and accurate readings.

Moreover, the heat meter also considers the temperature difference at the inlet and outlet, which is beneficial for the consumer. Similarly, it is most common type of heat meter

2-Ultrasonic

It measures several indicators: temperature and pressure of the coolant, flow part and volume. The calculation in this case is super accurate. It is common in open and closed systems. Furthermore, this include trunk and general buildings (practically without restrictions on the area).

The ultrasonic flow meter is the main component. Advantages - reliability and accurate data, disadvantages - sensitivity to impurities, debris and even air bubbles.

3-Mechanical

The budget option, in which the fluid flow is converted by rotating the measuring element. A mechanical flowmeter is the main component of such a device, modifications: vane and turbine (rotation parallel or perpendicular to the flow).

For reliability, the installation comes by a mesh filter that prevents equipment clogging. Common for locations with an area not exceeding 100 sq. M., is easy to mount in any position. Mechanical heat meters do not connect to the mains.

Important considerations for heat meters

Payments come in the case of an installed individual heat metering device involving straight and zigzag channel flow plates. If the equipment is in the apartment, it is enough to transfer the readings.

Directed to company supplying the services (or enter them into the payment document yourself).

5 Steps of installation for zigzag channel flow plates

- First, obtain technical specifications from the managing organization

- Second, technical specifications are to note before designing.

- Third; development of the design part and purchase of the device

- Moreover, coordination of the project context with the management service.

- Above all, installation of a heat meter and subsequent commissioning.

The final stage for straight and zigzag channel flow plates is drawing up an act of completed work and concluding an agreement with the management company. Please note for correct operation of the device, it is important to install a thermostat.

This is a device that analyzes the temperature indicators of the air outside and, according to them, adjusts the temperature in the heating system. Furthermore, you would hence get the desired results accurately.