Advantages of water cooling method using Plate Heat Exchanger:

In the current production conditions, especially in the industries of food, food processing, seafood, paper, textiles, tobacco, beverage, etc. Plate heat exchangers have an important role in manufacturing plants.

Plate heat exchangers are is considered productive and efficient workers. So what is a heat exchanger? How are they applied and classified? Along with us to find answers in the article you!

What is a plate heat exchanger?

A plate heat exchanger is a device is common to exchange heat between one or more heat carriers. Heat carriers can be separated by tubes or plates to prevent mixing or direct contact between the heat carriers.

You can understand simply, a heat exchanger is a manufactured device common to efficiently transfer heat from one part to another. And the heat transfer media can be separated by a solid wall so that they do not mix.

Application of heat exchanger

It is an important device, widely common in many different fields. Here are some basic applications of plate heat exchangers :

- Firstly, ship Technology

- Secondly, steam heating

- Also, vacuum condensing

- Moreover, camshaft oil cooling

- seawater central cooling

- Finally, oil cooling.

- Chemical technology:

The plate heat exchanger is common to make EO/EG heat exchanger, VOC condenser. High pressure and high-temperature waste heat recovery system. The ethanol condensing system, heats, cools, and condenses a variety of liquids such as sulfuric acid, acrylic acid, and fatty acids.

Heat exchangers are the fundamental heat move gear utilized in Chemical Process ventures for a wide scope of utilizations. And changing temperature necessities of streams in a compound interaction works with the utilization of a warmth exchanger

2. Other applications of plate heat exchanger

- Firstly, industrial refrigeration system: Evaporating or condensing

- Central water heating system, equipment to create hot water quickly using steam.

- The Inter concepter building depressurize uses a plate heat exchanger.

- Moreover, chiller Heat Recovery System.

- Solar system heat exchanger, heat pump.

- Paper technology: Waste heat recovery, paper coloring, etc.

- Plate heat exchangersare commonly common in food and beverage technology.

- Also, be common for pasteurization, sterilization, preservation of food and beverages.

- Textile technology: Heat recovery in the washing and washing process.

- Cooling of ammonia, benzene, heating, or heat recovery of CO2 evaporation.

- Power industry: Heat exchanger common to cool turbine oil using lake water, spring water.

- Moreover, a plate heat exchangersin the solar system.

- Use available water from the cooling tower in the production system.

- Easy to replace accessories due to detachable construction

- Pumps and pipes available in the system can be common

- Easy to disassemble and clean the plate heat exchanger due to its structure.

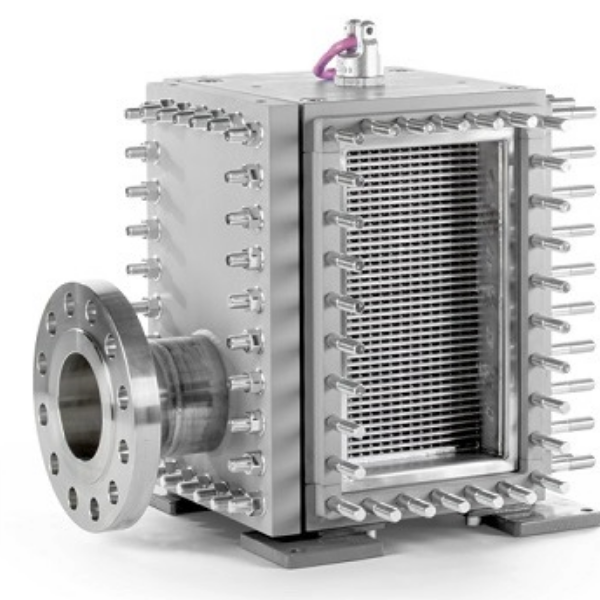

Different types of welded plates

PHE plate heat exchanger, BHE welded plate has many outstanding advantages. When integrating the system, will eliminate the disadvantages of the most beam and spiral condensers.

However is necessary to supply cold liquid heat sources, not use the wind to cool down. Maximum exchange temperature range (max: 50-60 degrees Celsius).Maximum temperature tolerable: 180 degrees Celsius. The highest pressure withstand is about 40 bar (kg/cm2).

Heating using a steam boiler

Gas and oil are supplied to the combustion chamber. When burning to cool down, the temperature of the combustion chamber can be up to 350 degrees Celsius. The heat is spread through the beam tube system in the boiler, transferring heat to the water outside the tube.

The water is heated up to 150 degrees Celsius, in the plate heat exchanger. There is a pressure regulating valve so that hot steam moves through the pipeline system.

Disadvantages of plate heat exchanger systems:

Consume a lot of electricity and fuel: The steam loop is an open loop, always needs to supply water to the boiler, the input water has the same temperature as the environment. Hence the amount of heat required is very large to heat water from 32 degrees -150 degrees Celsius.

Must treat the input water or ensure minimum cleanliness of plate heat exchanger. The steam generated does not corrode the pipeline system May have to pre-program your evaporator assuming you need high temp water at a particular time.

Example of solution tank heating by boiler

A heating system using a boiler without an integrated plate condenser. Also, a heating system using a boiler without an integrated plate heat exchanger. Also, the heating system using boiler without integrated plate heat exchanger

A heating system using boiler without integrated plate heat exchanger Hot steam from the boiler passes through the pipeline system.

Disadvantages of heating systems using boilers without integrated plate heat exchangers:

Causing pollution, adversely affecting the health of operators. In a plate heat exchanger, the hot steam is an open loop, after purging through the tank of solutions and chemicals, it will evaporate in the factory. Increased costs for fuel and water to compensate.

While the hot steam after surging through the tank is not recommon. Also, the solution tank has an uneven temperature, the flexibility of the molecules in the tank is not high. Increases precipitation and sedimentation for the solution tank if the water supply is not clean

a. Classification of heat exchangers based on the structure

As one of the most widely common forms of heat exchanger in all industries, an estimated 60% of the world's heat exchangers today are tubular plate heat exchangers.

- The device consists of a bundle of tubes inside through which a liquid needs to heat or cooled.

- Beam tube heat exchangers are commonly common for applications requiring high working pressures and temperatures.

- The heat exchange medium can be liquid, gas, gas, or vapor.

Factors on which beam depends

The flow in a beam tube heat exchanger can be unidirectional, horizontal, or helical. Also, the beam tube plate heat exchanger depends on several factors:

- Tube size: Using small tubes will reduce costs, compact equipment

- Conversely, it will be difficult to clean and dirty small tubes.

- Pipe thickness decided on heat transfer coefficient, abrasion, equipment weight, availability of spare parts.

- Pipe length, the distance between pipes, baffles