Micro-channel plate systems for industrial premises

INTRODUCTION

Radiant porous micro-fluid channel plate provides a higher temperature of the inner surfaces of the enclosures in comparison with convective heating, which means that human comfort is easy to achieve at a lower temperature of the indoor air.

In China, the industrial industry is show through many industries, such as:

- Mechanical engineering;

- Also, Metallurgy;

- Moreover, Chemical industry;

- Furthermore, Extraction, and processing of hydrocarbons;

- In addition, Agricultural sector.

These industries include large complexes of manufacturing plants.

In turn, the enterprise consists of several interconnected buildings and structures.

Almost every building needs heating during the cold season.

Heating a complex of industrial buildings and structures is a difficult task.

To assess how to heat buildings, it is necessary to develop a feasibility study (FS) of various technical solutions, considering the regulatory documentation.

For example, if you build one common boiler room on the territory of the plant, then each building will receive the coolant through pipelines. But then there are more for the construction of heating networks, and the equipment in the boiler house of significant capacity.

In this article, we will consider the types of Porous micro-fluid channel plate systems that are common in production workshops.

WHAT TYPE OF HEATING OF THE PRODUCTION HALL TO CHOOSE

The internal air temperature and the ways of organizing the microchannel plate system in the production workshop will depend on the following points:

- The presence of permanent jobs.

A permanent workplace is a place where a worker spends most of his time (more than 50% or more than 2 hours continuously). Such a definition governs by GOST 12.1.005-88.

If there are no jobs, then there is no need to heat the workshop to 18-20 ° С, as a rule, it is possible to provide for "standby heating" at 5 ° С.

Technological requirements for the production process or product.

For example, if processes with a large release of heat occur in a workshop, this factor must be considered when calculating the power of the Porous micro-fluid channel plate system.

Otherwise, a situation may occur when the calculation is made for an internal air temperature of + 20 ° С, but in fact the air temperature in the workshop is 40 ° С or more.

Overall dimensions of the workshop.

Production buildings are often of great height, and, as a rule, there is no need to heat the entire volume of the workshop.

The heating of premises usually classifies according to the method of heat transfer into two groups:

- Convective;

- Also, Radiant.

With convective heating, the internal air of the room heats, and then the air heats the objects inside the room. Registers, heating and ventilation units, heat guns, heat curtains transfer heat to the air.

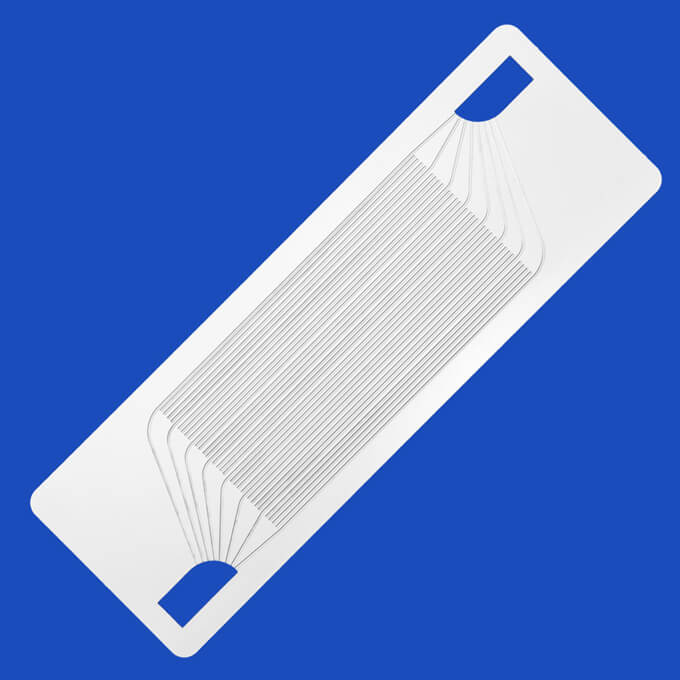

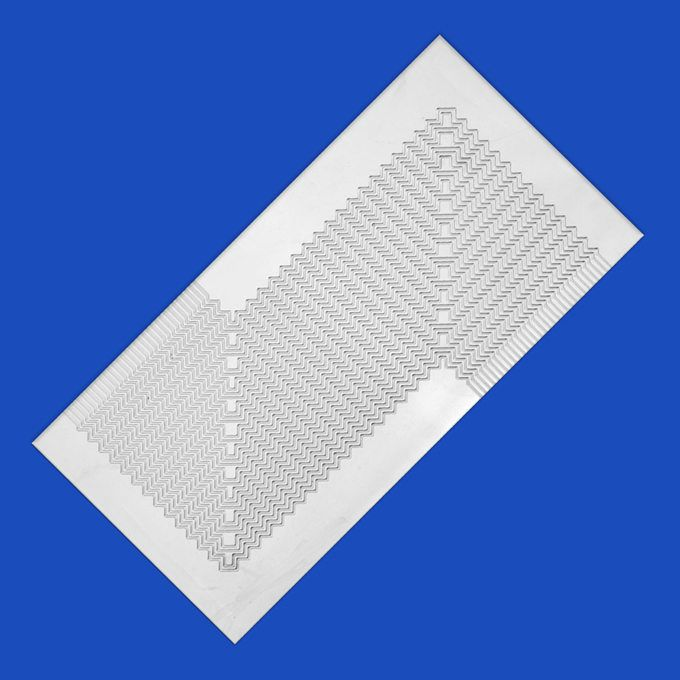

Method. 2. The principle of operation of Porous micro-fluid channel plate

With radiant heating, objects are first heated, and already air from them.

Method. 3. The principle of operation of radiant heating

Various fuels serve as a source for all types of heating:

- Gas;

- Also, Electricity;

- Moreover, Diesel fuel.

WATER HEATING

In production halls, as well as in other buildings, Porous micro-fluid channel plate systems are common, in which the heat carrier is water. But as heating devices, no radiators are common, but registers made of smooth pipes.

Method. 4. Heating of the workshop with registers

It is much easier to clean the registered surface from dust, oil, and other industrial substances than the radiator surface. In addition, there is a possibility of damage to the heater in the workshop, but if registers are installed, then the company always has a welder who can easily weld a section of the damaged register.

Pros of using registers:

- Ease of manufacture and installation.

- Also, Low cost.

- Moreover, Insensitive to pressure drops.

- Furthermore, Withstand pressure up to 1 MPa.

This type of heating is suitable for workshops in the following cases:

- There is a free zone of external fences, where heating devices are usually installed;

- The enterprise has a boiler room where the heat carrier is prepared.

AIR HEATING

Air microchannel Porous micro-fluid channel plate systems are called hot air systems. Such systems are also referred to as convective heating.

Distinguish between local and central air microchannel plate systems.

Local air Porous micro-fluid channel plate

Such systems are represented by various heating and ventilation units, heat guns, air curtains.

Method. 5. Heating of the workshop with heating and ventilation units

The principle of operation of heating and ventilation units

Method. 6. Operation of the heating and ventilation unit

Internal air from the workshop enters the unit with the help of a fan, then it is heated in a heater (heat exchanger), then it is fed back into the workshop space. Thus, these units operate on the recirculation principle. Heaters are usually water heaters.

Advantages of Porous micro-fluid channel plate and ventilation units:

- The heat spreads evenly throughout the room.

- The flow of warm air is easy to direct to the desired point in the workshop, the blinds change their direction.

Disadvantages of using heating and ventilation units:

- A heat carrier requires heating the air in the heater.

- For installation, competent personnel require since the system must be installed in strict accordance with the recommendations of the manufacturers, it is necessary to provide for the installation of air vents, drains in the right places of the system, otherwise this Porous micro-fluid channel platesystem will simply not work.

Heat guns

Heat guns also work on the principle of air recirculation. Heating elements in this case are heating elements. Also on the market are heat guns operating on diesel fuel or gas.

Pros of using heat guns:

- They do not require installation and are easy to direct move around the workshop.

- Rapid healing of internal air to the required temperature.

Disadvantages of using Porous micro-fluid channel plate:

- It is necessary to constantly monitor personnel, since the operation of such units cannot be automated.

- There is a risk of overheating of this unit and, as a result, a fire.

- In the case of using diesel heat guns, combustion products may enter the air of the room, as a result of personnel poisoning.

Summary

As a rule, registers come of electric-welded steel pipes in accordance with GOST 10704-91. But in the case when the internal environment of the room is aggressive, then registers and pipes must be common from stainless steel. This type of Porous micro-fluid channel plate system belongs to convection.