Introduction of micro channel heat exchanger

A micro channel heat exchanger is a device in which the process of energy (heat) exchange between media of different temperatures takes place. The specific parameters and characteristics of the equipment depend on its type.

All devices divide into two large groups. Also, in some environments they mix with each other, in others they are separated by a wall. Moreover, the latter are common more often. Similarly, there are regenerative and recuperative installations, depending on the direction of the coolant flow.

Micro channel heat exchanger by design and features

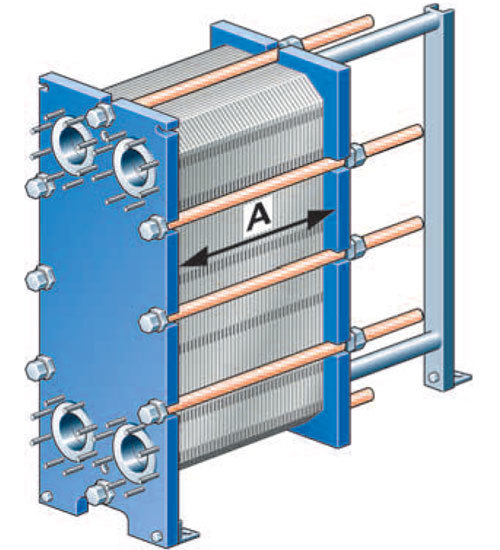

By design features, devices with a flat surface (lamellar, spiral) and tubular (shell-and-tube, serpentine, "pipe-in-pipe") are divided.

Also, when choosing Micro channel heat exchanger, you need to pay attention to several parameters. Let's start in order.

Basic characteristics

Regardless of the type of device, the main parameters must be considered:

Micro channel heat exchanger area:

This is the area of one surface of the product multiplied by the number of surfaces. Plus, it is influenced by other factors: pressure loss during operation, additional area resources in case of deposits, heat transfer coefficient and speed in the channels.

Heat exchanger power. The amount of heat generated by the device.

Dimensions and weight. It will depend on them whether the equipment will cope with the task at hand. They also affect the amount of materials required for the manufacture of the device.

Next, it is necessary to determine the technical conditions for using the equipment.

Also, when choosing a Micro channel heat exchanger, also, it is important to understand in what conditions it will work.

The type of environment. Steam, water, oil, and gas are usually common as heat carriers. The structure of the device will affect the calculations and further selection, since aggressive substances require increased strength properties of the device.

Micro channel heat exchanger Technical operating conditions

When using non-standard media, the values of heat capacity, viscosity and thermal conductivity of the heat carrier may be required.

Working medium consumption. Also, you need to know what mass of the working medium passes through the Micro channel heat exchanger unit in a certain period.

Temperatures of media at the outlets and inlets of the heat exchanger is important. Also, The greater this difference, the cheaper and smaller the device.

Micro channel heat exchanger Allowable pressure

Allowable pressure losses of the heated and cooled sides. When the heat carrier and heat consumer pass through the heat exchanger, the pressure of the working medium drops.

Also, it is important to take this into account when choosing, because too much pressure drop of the liquid will not allow, for example, lifting it to the upper floors of the building.

Maximum operating temperature:

Moreover, the higher the temperature inside the equipment, the more stringent the requirements for the design of the heat exchanger and the materials of its manufacture will be.

Micro channel heat exchanger Maximum working pressure

Maximum working pressure. Like the previous point, the higher the pressure inside the Micro channel heat exchanger, the more serious the requirements for its design features and materials common in the design.

Heat load. The ability of a heat exchanger to transfer an amount of energy from one medium to another. Equipment with high heat load rates is usually large and operates under high pressure.

Also, based on the technical operating conditions, the heat exchanger calculates.

Micro channel heat exchanger Calculation options

There are eight ways to calculate equipment, each is needed for its own purposes and tasks.

Thermal calculation. They are common in the design of heat exchangers of known power and in the installation of finished installations under specified conditions. Also, the main task of this calculation is to determine the optimal type of device and the shape of the heat exchange surface.

Additionally, it allows you to determine the efficiency of heat transfer, the area of the heat exchange surface, the mass flow rate of the coolant and its outlet temperature.

Micro channel heat exchanger the basis for the calculation

The Micro channel heat exchanger equation is:

Q = F‧k‧Δt, where:

Q is the size of the heat flux, W.

F is the area of the working surface, m2.

k is the heat transfer coefficient.

Δt is the difference between the temperatures of the carriers at the exit to the apparatus and at the exit from it. Also called the temperature head.

Composite calculation. Allows you to determine the optimal mutual arrangement of the heat exchanger channels for different heat transfer fluids.

Derives from the thermal calculation and uses its results.

The specific calculation formula is determined by the type of Micro channel heat exchanger and its design features.

Verification calculation. It carries out built on a thermal calculation and is future to test the ability of the installation to cope with the task at hand in specific conditions. Also, to perform it, you need to know the thermal performance and the parameters of the thermal environment.

Hydraulic calculation. Allows you to calculate the hydraulic parameters of the coolant necessary for operation, for example, the speed of its movement.

Micro channel heat exchanger Constructive calculation

It carries out at the design stage of a heat exchange device to determine the type of product itself. With its help, the required number of plates of the plate heat exchanger, the number of pipes and their length, the diameter and height of the device in the shell-and-tube device calculate.

Moreover, the initial data are the results of thermal and hydraulic calculations.

Mechanical calculation:

It determines the ability of the structure of the Micro channel heat exchanger to withstand the factors of internal and external mechanical stress: bending, compression, tension, and the like.

In short, the calculation comes like this:

Choose a material for the manufacture of structural elements.

The thickness of the body wall calculate considering the voltage, the diameter of the heat exchanger and the design pressure.

Also, the thickness of the bottom calculate takes into account its shape.

Calculation of the device supports is performing, taking into account the type of support, the number of supports and their design.

Calculate the maximum weight of the apparatus.

Check the strength of the foundation. Furthermore, the stress of the foundation material must be greater than the stress of the supporting surface.

Calculation of temperature stresses. However, they are common to determine the change in the geometric shape of the Micro channel heat exchanger and its individual elements under heat exposure and to identify stress points arising from thermal expansion. This allows you to correctly select the materials from which the elements of the equipment make.

Conclusion

Strength calculation. It combines the three types listed above - mechanical, hydraulic and calculation of temperature stresses. Checks how the installation can withstand all types of stress arising under the influence of any possible factors.