Understanding of build craft heat exchanger

The main parts of the device build craft heat exchanger are rectangular panels with very thin thickness and made of stainless steel. Furthermore, each panel will have four holes at the four corners and a system of grooves throughout the surface to create turbulence and increase heat transfer area.

Thin plate construction of the device

When the thin panels are put together on the chassis of the device, it forms the inlet and outlet systems for the sample and the heat carrier. Moreover, depending on the specific situation, JIMEI will assign the system appropriate paths.

- Firstly, according to the heat exchanger surface shape and material

- Secondly, according to the purpose of using the working medium

- Lastly,build craft heat exchanger is in the direction of motion of the medium

The basic type of plate heat exchanger

The main characteristics of the plate heat exchanger are structure, shape, channel, for working medium; The channel is located between adjacent plates, often having a narrow-slit shape

Foldable plate heat exchanger

Used for heating corrosive, deposit-prone media, which easily form deposits with sub-thermic resistance. Moreover, this increases hydraulic resistance if they are too thick, reducing heat exchange efficiency between the media

Semi-assembled plate build craft heat exchanger

Moreover, thanks to the rubber seal, we can create separate heat exchange surfaces, after a period of work, due to dirt; we must remove them to clean. And use build craft heat exchanger and avail maximum benefits from it.

Block plate build craft heat exchanger

Used to heat or cool fluids, as well as to condense clean steam. Furthermore, the basic elements of this type of equipment are standardized blocks, which are also fabricated from pre-stamped sheets welded together.

Rigid welded plate type heat exchanger

The problem of increasing the efficiency of the heat transfer process of heat exchangers to meet the actual technical requirements, reducing investment costs, operating costs. And having a compact size is one of the research directions.

It is of interest to researchers and manufacturers. In recent years, heat exchangers with high-density heat exchanger surfaces (compact heat exchangers). Build craft heat exchanger; with many different structures have been widely used to replace traditional heat exchangers. Lastly, beam-tube heat exchanger is promoting its efficiency thanks to its outstanding advantages.

Types of build craft heat exchanger

Heat exchangers with high heat exchanger surface density are typically of the following types:

- Plate Heat Exchanger

- Spiral Heat Exchanger

- Spiral Heat Exchanger

Furthermore, plate and Shell heat exchangers, Pack inox heat exchangers and other special types of equipment.

These types of devices will be presented in the following sections. Types of build heat exchanger with high heat exchanger surface density. In addition, heat exchangers with high heat exchange surface density are divided into many forms. Above all, it is with different operating principal structures. Below are the basic types that are commonly used today.

Plate-frame build craft heat exchanger

Plate heat exchangers are now widely used in industries and are second in terms of overall heat exchanger market share. However, in the oil and gas processing industry, this type of equipment is also used relatively modestly due to some structural characteristics.

The plate-frame heat exchanger, from the outside, is structured like a plate-frame press, consisting of many embossed thin plates pressed together. It comes between the plates forming a space for the heat exchangers fluid flows through.

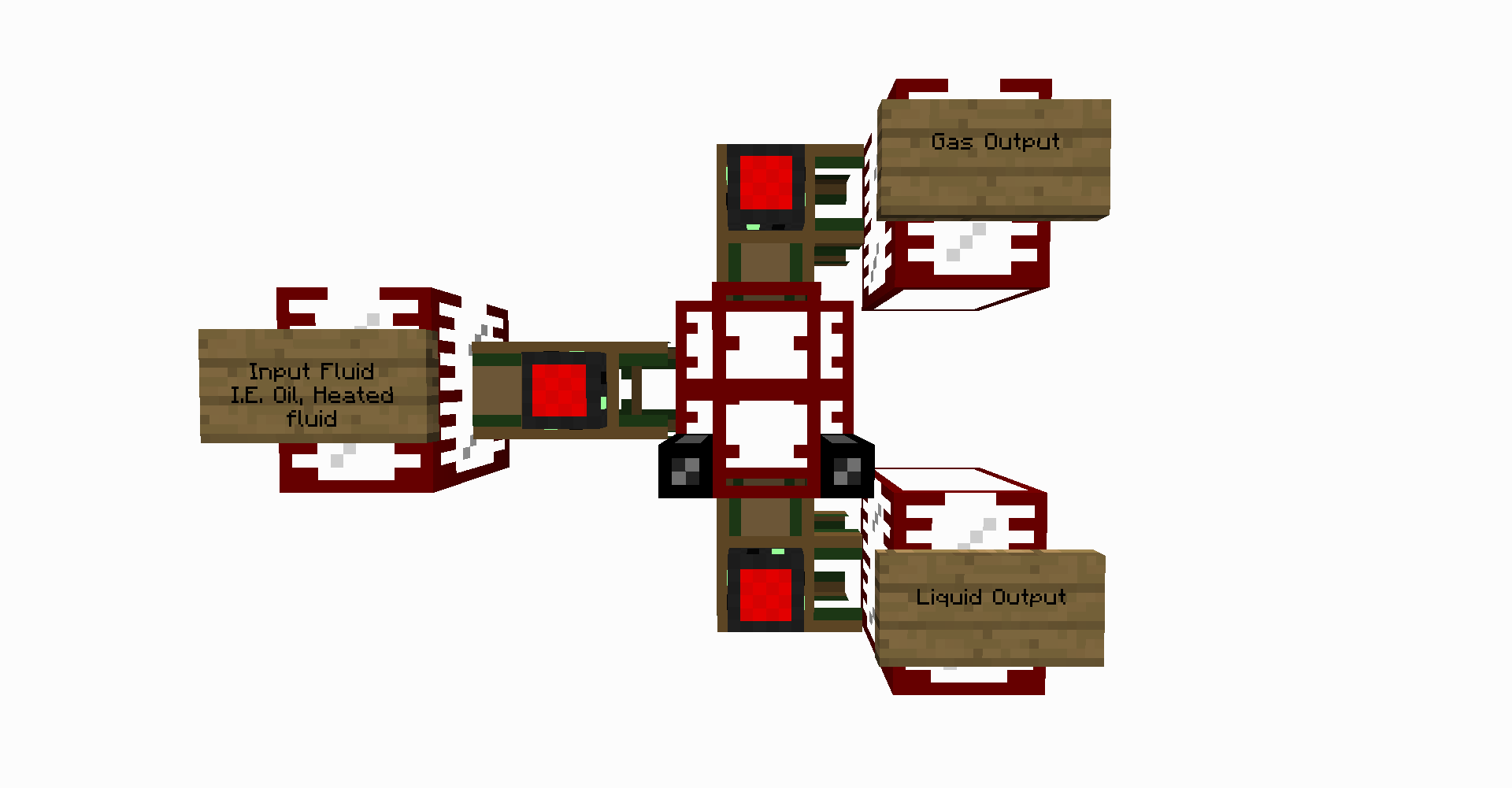

Fluids of heat exchanger

The fluids are usually arranged to flow in opposite directions to increase the efficiency of the heat transfer process. Furthermore, in build craft heat. Moreover, thanks to this structure, the device has a relatively large heat exchanger surface when it is the same size as a traditional heat exchanger.

Structure and working principle of build craft heat exchanger

Plate-frame heat exchangers can basically be divided into two main parts:

- First, frame part

- Second, heat exchanger surface

Frame part; build craft heat exchanger

The equipment frame is responsible for supporting all the heat exchanger plates, the amount of liquid contained in the device, creating a structure to position and squeeze the heat exchanger plates together into a block of heat exchanger plates.

Make sure not to let the fluids leak to the outside. The equipment frame consists of the following main details:

- First, fixed head

- Second, movable head in craft heat exchanger

- Moreover, support frame

- Also, lower, and upper plate heat exchanger support

- Additionally, and locating rods,

- Above all, bolt bars to tighten the heat exchanger plates. Close together.

Heat exchanger surface part; build heat exchanger

The heat exchanger surface consists of many thin metal plates that are embossed with ribs. Direction of stamping ribs on non-directional heat exchanger plates. Moreover, it is to avoid creating dead zones and minimizing deposit formation. These ribbed metal plates form a plate heat exchanger.

The heat exchanger plates are joined together to form a hollow space between the two plates. And fluid flows through these narrow slits and heat transfer occurs across the surface of these heat exchangers. To prevent fluids from mixing in build craft heat exchanger.

Sealing ring and build heat exchanger

Apart from this, the heat exchanger plates are clamped together into a unit by a movable plate (moving head), fixed plate (fixed end) and bolts.

Working principle of build craft heat exchanger

The operating principle of the plate-frame heat exchanger is to create the flow of fluids in opposite directions on the surface of the heat exchanger plates to enhance the heat transfer process. The heat exchanger plates, when pressed together, form narrow slots to allow the fluids to alternate between each other.

In a heat exchanger it is possible to arrange a single flow or a dual flow (flow of the fluid in the device can be divided into several directions. And there are many parallel streams i craft heat exchanger.

Scope of application of build craft heat exchanger

There is a wide application area for build craft heat exchanger. Besides, plate heat exchangers have a wide range of applications. More importantly, these are especially for heating and cooling processes such as:

- First, condensation process

- Second, evaporation process