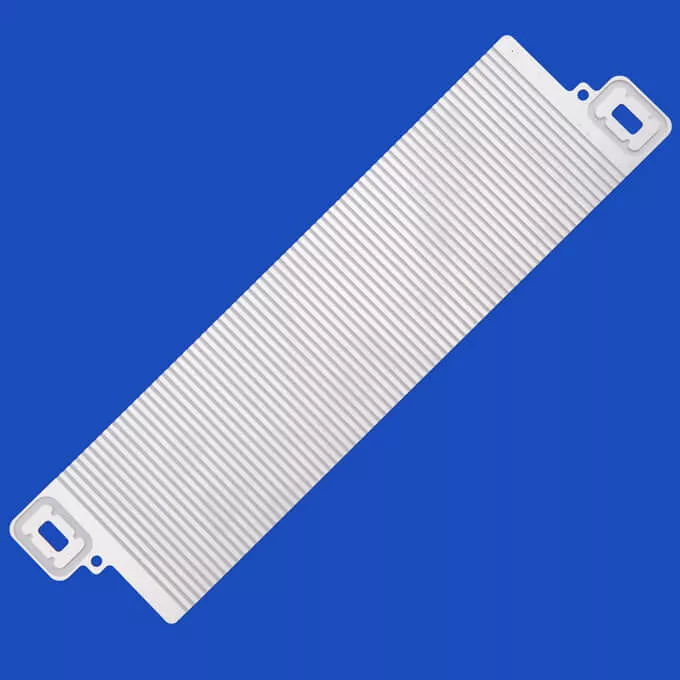

The stainless-steel micro channel perforated plate is a device that allows the temperature crossing through thermal energy from a fluid at a higher temperature to one at a lower temperature.

Stainless steel micro channel plate Performs a double function

- Changes the thermodynamic state of a fluid current by thermal interaction with another.

- It allows the transfer of a thermal power between a solid surface and a fluid current.

The three types of stainless-steel micro channel perforated plate process

Moreover, the heat exchange process between two fluids can carry out in various ways. There are three types of exchange that can define on the basis of various factors:

- Construction materials;

- Type of fluids that evolve there;

- Thermo-fluid dynamic design.

In practice, the stainless-steel micro channel perforated plate process is simple. In fact, section by section there is always a temperature difference between the fluid at a higher temperature (hot fluid). Moreover, that at a lower temperature (cold fluid) which allows the transfer of energy between the two.

The temperature crossing of a heat exchanger

The term “temperature crossing” describes the scenario in which the outlet temperature of the cold fluid is higher than the outlet temperature of the hot fluid.

Moreover, to obtain a crossing of temperatures, the fluids must be in countercurrent, i.e. However, the inlet of one fluid must be in correspondence with the outlet of the other.

Furthermore, the number of passages through the exchanger must be one for both fluids only.

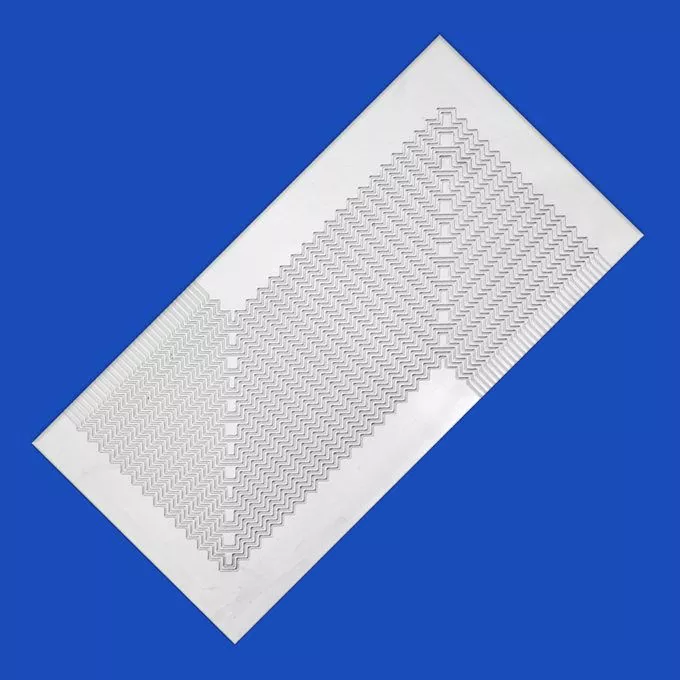

The internal passages of the fluids in stainless-steel micro channel perforated plate

In a heat exchanger, the fluid flowing on the side of the tubes can make only one passage to go from the inlet to the outlet. Moreover, it can make two or more, even reaching eight “back and forth” passages. However, the number of passages normally link to the temperatures of the fluids and their flow rate.

If the quantity of fluid is low, its velocity inside the exchanger is similarly low, drastically reducing the exchange capacity.

By passing the fluid inside the exchanger several times, the section available for each passage reduces. Therefore, the speed increases, favoring the heat exchange.

Stainless-steel micro channel perforated plate Maintenance

Maintenance and periodic cleaning of the exchanger are necessary to keep the machinery in perfect condition and ensure the best operating conditions of a heat exchanger.

However, not all maintenance is the same and takes the same time. Intervention times vary depending on:

- The type of fluid contained

- From the impurities or deposits present

- From the operating temperatures

We will answer the most common questions about Heat Exchanger Maintenance

In this arctic you will find:

- Heat Exchanger Maintenance

- Why Perform Heat Exchanger Maintenance?

- Who has to carry out the maintenance?

- How often should the Maintenance be done?

- Identify cracks or corrosion in the pipes

- Maintenance components of stainless-steel micro channel perforated plate

- Pipe maintenance

- Seals maintenance

- Upholstery maintenance

- Incrustations

The thickness of the encrustations increases, the difficulty of cleaning also increases.

The heat output of the exchanger that decreases or the pressure drops of the fluid that increase are symptoms that indicate that the heat exchanger needs cleaning.

Failure to clean the pipes can cause different thermal expansions

Moreover, the consequent deposit of encrustation can cause a different thermal output between the pipes, even adjacent ones, can cause different thermal expansions between pipes with a possible consequent breakage.

It's important:

- Never disassemble the covers of the casing or of the floating heads without first stopping the system, completely removing pressure from the appliance and emptying it.

- Moreover, always use adequate means of individual protection based on the fluids contained in the stainless-steel micro channel perforated plateand, if necessary, ventilate the room.

- To clean or inspect the inside of the pipes, remove only the necessary covers on the pipe side; to clean the outside of the tubes it is necessary to extract the tube bundle.

- Pay attention to the fact that not all heat exchangers are of the withdrawable type; however, in this case, a chemical wash usually carries out, by circulating a product that washes the surfaces inside the mantle. Read also: Components of the Heat Exchanger

Why Perform Heat Exchanger Maintenance?

A heat exchanger is a particular piece of equipment. It is often subject to the control of external bodies. Its duration calculates to reach at least ten years. However, it is subject to encrustations that can significantly reduce the exchange in stainless-steel micro channel perforated plate.

Therefore, we will have to proceed with a strict periodicity, which can go from six months to a year, to clean the internal and external pipes with simple operations that indicate in the booklet. instructions.

Who has to carry out the maintenance?

Moreover, all operations must carry out by specialized personnel given the danger of the equipment which operates at high temperatures, sometimes even with steam or diathermic oil. However, the specialized personnel will procure original spare parts in advance to correctly refurbish the equipment itself.

However, failure to clean the stainless-steel micro channel perforated plate can lead to deterioration and lower performance, but it can also cause breakages that can cause damage to people and property. Therefore, beyond having to keep the guarantee active, and to comply with the regulations in force, the maintenance of these equipment is very important.

How often should the Maintenance be done?

Let's see the cadences with which these maintenances must be done.

- Every six months a cleaning and a check of the tightening of the flanges and pipes must carry out.

- The internal and external cleaning of the stainless-steel micro channel perforated platemust be carried out every year or two years at the latest.

- Moreover, an integrity test must carry out every 10 years which will carry out in collaboration with an external body.

In any case, you will find all the details and operations to carry out in our maintenance booklets where there will be a special space for signing and the date of the maintenance.

Identify cracks or corrosion in the pipes

Moreover, to identify cracks or corrosion in the pipes of stainless-steel micro channel perforated plate or leaks in the fittings between pipes and tubes. It is recommended to use the following procedure:

- Remove the covers from the tube side;

- Pressurize the shell, without exceeding the maximum test pressure, using a cold liquid;

- Observe the expansion or welds of the tubes and adjacent areas, the inside of the tubes and the tube sheet.