When there is a large difference between the flow rates (or between the maximum allowable pressure drop) of the two fluids, the stainless-steel micro channel plate can run twice through the fluid with a lower flow (or higher losses) to balance the pressure drops values or specific flows in the channels.

The different configurations: in parallel, in series and mixed.

One of the most common problems with plate heat exchangers is the uneven supply of all channels in parallel. In fact, the fluid tends to distribute itself in greater amounts in the first channels than in the last ones, in order to balance the pressure, drop.

As the number of plates increases, the uniform distribution decreases, resulting in a decrease in the overall performance of the exchanger.

There are two basic types of plate heat exchangers: micro Plate Heat Exchangers and PHE-Plate Heat Exchangers.

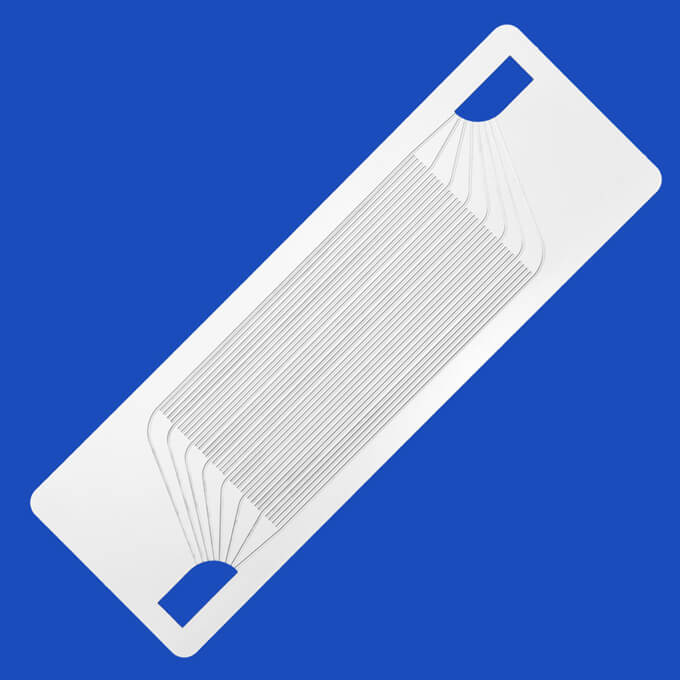

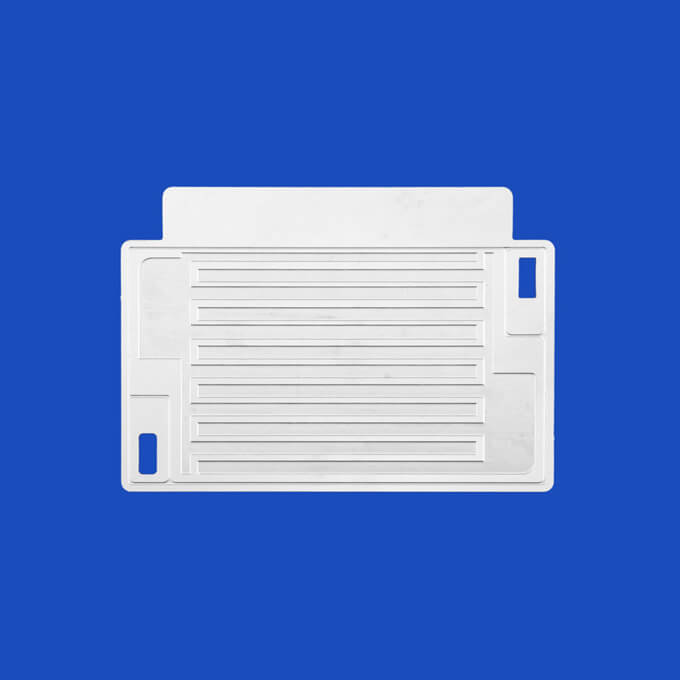

Frame stainless steel micro channel plate

In PHE the plates create a frame where the plates are pressed with heads and connecting bars, and sealing is guaranteed by gaskets. The gaskets, in addition to the sealing effect, serve to direct the flow of fluids and are placed along the grooves on the edges of the plates.

The maximum temperatures used for sealing the heat exchangers are between 80°C and 200°C, while the pressures can reach 25 bar.

Various types of butyl or silicone rubber

The main features of these types of stainless-steel micro channel plate are:

- Quick and easy disassembly for cleaning and control operations

- Adaptation to changing operating conditions by adding or removing heat plates to modify the installed heat flow

- Possible fluid leaks due to the non-perfect seal of the gaskets do not contaminate the other fluid, but are directed away

- Materials that are poorly suited for welding, such as titanium, can be used

- Gaskets limit the maximum pressure and temperature values

- Potentially high costs due to the design of molds, presses and the entire production process

- High cost of gaskets

Brazed heat exchangers

Brazed plate heat exchangers do not have heads, connecting bars or sealing gaskets because the plates are brazed in an oven at temperatures of 1100 °C.

During the assembly phase, a sheet of brazing material (usually copper, but also nickel) is placed between the plates, the package is pressed and then baked for a few hours.

Stainless steel micro channel plate exchanger is more compact, lighter and less bulky than one with gaskets.

The path taken by the hot and cold fluid in micro channel plate

The brazing material performs the function of both the joints and the structure. These exchangers are generally used with chevron corrugated plates, which are assembled by alternating corrugation directions to create a network contact.

The crossing points between the undulations of two coupled plates form a dense network of contact points that provide pressure tightness and induce swirl currents that improve heat exchange.

In this way, fluid turbulence is high even at low nominal inlet velocities and the flow changes from laminar to turbulent at low flow rates.

A cross section of an exchanger

cross section of stainless-steel micro channel plate with 8 plates in total (6 of which are useful for heat exchange) in which the 3 channels used for the passage of the refrigerant fluid (in light blue) and the 4 for water (in red) are seen.

It is immediately noticed that the path taken by the fluids is chaotic, in fact, the cross section varies continuously.

Main disadvantage of exchangers

The main disadvantage of these exchangers is that they are not removable and therefore maintenance and cleaning is not possible or at least difficult, and there is no flexibility because the number of plates cannot be changed in any way.

The surface of the stainless-steel micro channel plate is undulating to increase fluid turbulence during flow into the channels.

The main geometric parameters of the ripple

Ripple step p; ripple height b and chevron angle β compared to the main flow direction.

The slope of the plate undulations has a determining effect on heat exchange and pressure drops. In fact, a pair of plates with a high β angle (> 45°) gives a turbulence and therefore a high heat exchange with a larger pressure drop.

Lower heat exchange coefficients

A smaller angle (β < 45°) causes less turbulence flow and lower heat exchange coefficients in stainless steel micro channel plate, but also lower pressure drops. The search for a compromising angle β between high exchange coefficients and acceptable pressure drops is therefore essential.

The ripple height b has an important effect on the exchange coefficients because greater depth causes greater turbulence. The height and pitch of the ripples increase the exchange surface area of the plate: the surface widening factor φ is defined as:

Corrugated surface projection area of micro channel plate

The actual area is difficult to calculate, therefore, to compare different exchangers; reference is made to the projected area.

It should be borne in mind that stainless steel micro channel plate with the same projected area (ie plates of the same size) may have different effective areas depending on the value of the surface enlargement factor φ.

The ratio of plate length L to plate width W also affects performance, but to a lesser extent than other variables. In general, a high plate length-to-width ratio results in high exchange rates but higher pressure drops.

Conventional plates for diverse applications

Heat exchanger plates for the most diverse applications, with average channels that normally vary from 2.2-4.0[mm]. Due to the small spacing between the channels, it presents great turbulence and a high thermal efficiency. Between each stainless-steel micro channel plate, there is a gasket that is responsible for the tightness between fluids and the external environment. Used for the most diverse applications.

Semi-soldered plates

Specific plates for refrigeration, chemical processes and specific industrial processes, where they have a pair of welded plates, guaranteeing a more efficient sealing and safety to the fluid flowing in the channel (usually refrigerant gases).

Between these stainless-steel micro channel plate, called cassettes, gaskets and rings are used to seal the less aggressive secondary fluid. Average channels that typically range from 2.2-4.0[mm], having the same turbulent effect as conventional plates.