In the midst of an emerging industry such as China, new demands for thermal energy arise every day. Energy, both for cooling and industrial heating, is very common in stainless-steel micro channel porous plate processes that we all consume in our day-to-day.

Micro channel porous plate in industries

Beverages, for example, cool and heat in their pasteurization process, not only alcoholic ones, but also milk, juices and other types of liquid consumer products. Another very common demand and better known by the population is that of thermal exchange for the use of water in air conditioning systems.

In a shopping mall, for example, a very large heat load requires to meet sufficient calorie demand. In this case, the air conditioning installation has heat exchangers and chillers.

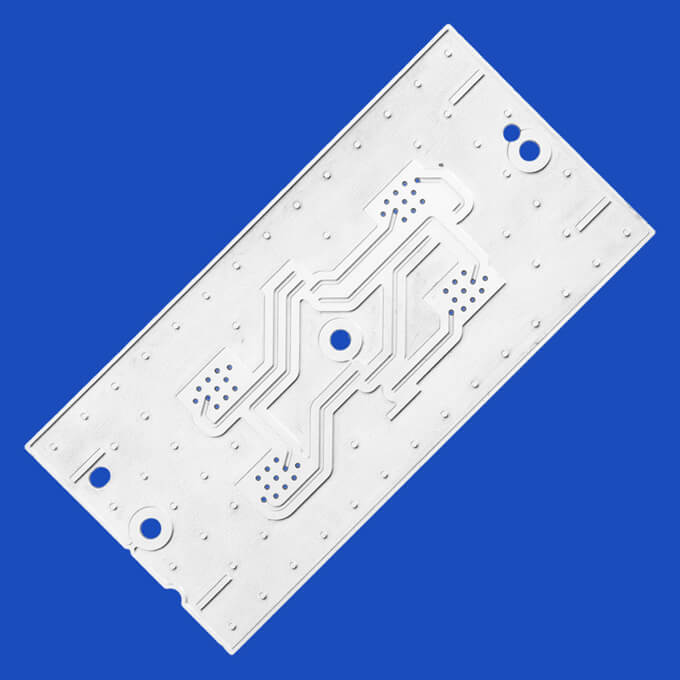

What is a stainless-steel micro channel porous plate?

The heat exchanger is an equipment good to exchange temperature between a primary and a secondary fluid. This reaches a certain temperature in one of these fluids. An example is the heating of water with the use of steam, regardless of the type of exchanger used.

Let's assume that we have water at an ambient temperature of 20 °C and we need to heat this water for pasteurization to 85 °C. For this process, in a heat exchanger, water at room temperature will enter on one side and steam on the other.

A sensor, solenoid valve and controller

Through the stainless-steel micro channel porous plate between the fluids, the cold water gets heat to the desired temperature. It comes with the help of automation with a sensor, solenoid valve and controller) and the steam. Losing calories will become condensed and will be automatically eliminated by a mechanical float trap.

Below we will talk a little more about some of the most common types of heat exchangers and their use in the industry.

Brazed plate heat exchangers

Brazed plate heat exchanger is the most common in the industry. As it is a heat exchanger of high thermal efficiency, in a small physical space, it promotes a large thermal exchange. And stainless-steel micro channel porous plate can also be good for high flow rates of fluids in systems with several exchangers in parallel. It can be in heat exchanger applications for pool or heat exchanger for chiller.

Brazed plate heat exchangers are widely common in equipment

They are also common in commercial refrigeration applications. They have the function of cooling water or other liquid for circulation, as part of a chiller.

Stainless-steel micro channel porous plate heat exchangers are the best on the market. They are good both in construction, strength and efficiency. The unique Micro plate technology offers higher flow in parallel with higher thermal efficiency.

Thus, with less energy expenditure, a greater delivery of the final product is important. Below is the code table of the most common Micro models of brazed plate heat exchangers. Here the number in bold refers to the number of plates.

Dismountable plate heat exchangers / porous heat exchanger

The stainless-steel micro channel porous plate, sanitary or not, can be small, medium or large. It can also have threaded, flanged or weldable connections. In addition to these characteristics, thousands of variables are easy to change and adapt to each process.

Common in different formats and quantities

It makes them great allies in the industrial market. In water heating systems with steam, industrial pasteurizer systems, systems for generating chilled water through ammonia and many others are good. They are common in different formats and quantities.

Advantage of this type of equipment

The great advantage of this type of equipment is the process flexibility. At any time you can increase or decrease the heat exchanger capacity by adding plates. Stainless-steel micro channel porous plate can improve its seal by adapting gasket materials and can change its basic characteristics. It is to suit the entry of new equipment or other new process conditions.

The plates and seals for heat exchangers are sold separately and here you will find a wide variety of gasket plates. These come of different materials and for the most varied applications on the market.

Shell-to-tube heat exchangers

Shell-in-tube heat exchangers are basically metallic containers with an internal coil that exchanges heat between the primary and secondary fluid. The great advantage of this stainless-steel micro channel porous plate is its robustness. On the other hand, the disadvantages are great when we talk about physical space and thermal efficiency.

For a large thermal exchange this equipment needs a large physical space to allocate. Shell-and-tube heat exchangers are increasingly in disuse and losing ground in the face of new technologies on the market.

What is the best type of heat exchanger?

This question is difficult and certainly does not have a conclusive answer. The best heat exchanger is the one that best suits your process. Moreover, it consumes less energy and generating greater efficiency with the given stainless-steel micro channel porous plate flow.

The brazed heat exchanger has great thermal efficiency, but does not allow maintenance and plate replacement. In turn, the detachable heat exchanger allows, in addition to maintenance, the expansion of capacity and adaptation to the current project due to its flexibility.

While for corrosive and high-pressure processes, the shell-in-tube heat exchanger may be the best option due to its robustness and wide range of industrial application.

Two important variables of the stainless-steel micro channel porous plate

Regardless of the heat exchanger model installed, it is important to take into account two very important variables related to this equipment:

- Ensuring periodic preventive maintenance of the equipment, cleaning, changing seals, plates, tests and respecting the useful life of the equipment.

- Ensuring that the fluids that enter the equipment are in the proper filtering, temperature and pressure conditions for the project. The operation and dimensioning of the equipment is in accordance with reality, working safely and with high efficiency.

Periodic revisions are necessary

The cleanliness of heat exchangers is essential for the food, chemical, steel and petrochemical industries to function perfectly. This is because the function of this stainless-steel micro channel porous plate is precisely to transfer heat from one fluid to another. Therefore, through this important function, some periodic revisions are necessary and this is what we will talk about here.

Chemical cleaning and mechanical cleaning: what's the difference?

Industrial cleaning methods differ according to the result to be achieved; in some cases, the combination of procedures is the best alternative for better maintenance. There are two recommended techniques for cleaning heat exchangers in plants, namely chemical cleaning and mechanical cleaning.

The time saving technique

With regard to chemical cleaning, the great positive point of this technique is the time saving. The use of acidic compounds makes the whole process more agile. It is also worth remembering that the indication of this method is relevant in stainless-steel micro channel porous plate.

It works with the handling of gases, water treatment, refrigeration systems, heating, among other utilities. In this way, problems such as erosion, cross contamination of fluids, obstructions, blockages and leaks are avoided.