Improving PCB with the Help of Thermal Heat Transfer Solutions

Also known as printed circuit boards, the PCB is the heart of any electronic device. They are extremely important in allowing the transmission of analog and electrical conditions between multiple electronic parts. That’s why you should use the best technology such as thermal heat transfer solutions during the development of PCB for electronic parts. Want to know what makes this technology one of the best technologies available out there. Keep reading then! We will tell you everything you need to know below.

Thermal Heat Transfer Solutions in PCB

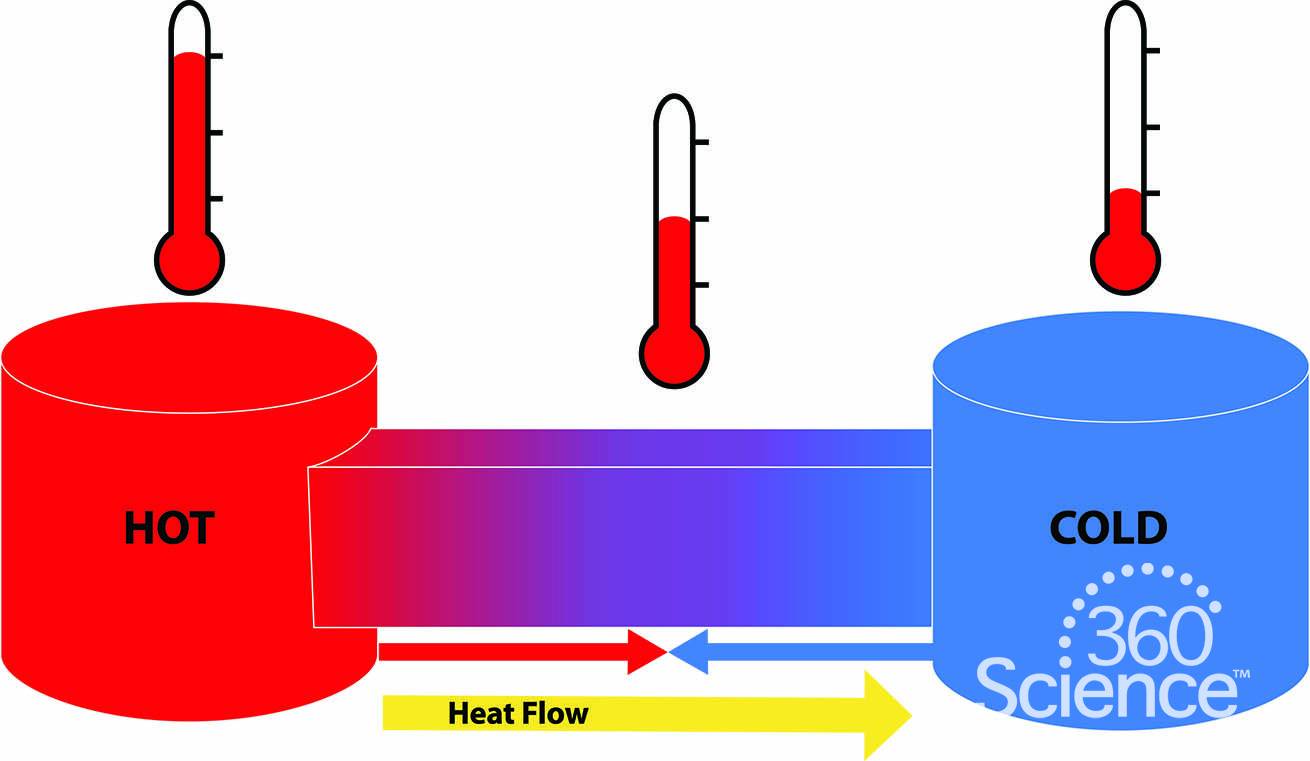

During its movement inside the PCB, power produces a pretty much high measure of warmth. This relies upon the measure of opposition it experiences. Notwithstanding follows, power parts, like MOSFETs, IGBTs, converters, and drivers, are essentially answerable for heat age.

The force supply voltages of exceptionally coordinated rationale gadgets. For example, DSPs, SoCs, and FPGAs are continuously diminishing. These gadgets additionally foster a non-unimportant measure of warmth. That's because of both high working frequencies and the escalated utilization of profoundly complex calculations.

Thermal heat transfer solutions are quite possibly the most basic and treacherous perspectives that fashioners face when planning a PCB. From one viewpoint, it is important to guarantee the right working and dependability of the circuit with each worth of voltage, current and allowable recurrence. On the other hand, it is important to regard the spending imperatives forced by the maker, restricting the utilization of bulky and costly cooling arrangements. An example of this is heat sinks, fans, or fluid cooling.

Importance of Thermal Heat Transfer Solutions in PCB

The thermal heat transfer solutions are quite important while developing the PCB. That’s because the current silicon-based segments have an intersection temperature between about 125°C and 200°C.

Notwithstanding, it is important to try not to arrive at this worth. However, the remaining existence of the part will fall apart quickly. Truth be told, it is assessed that an increment in working temperature of 20°C. That's because wasteful warm administration can lessen segment life by up to half.

High splendor LEDs, for example, convert more than 60% of the ingested power into warm and consequently require exceptional printed circuit sheets fit. This is important for taking care of high temperatures without harming the segments.

The developing prominence of wide band gap (WBG) semiconductors, like gallium arsenide (GaN) and silicon carbide (SiC), has permitted parts to arrive at higher working temperatures than silicon-based innovation.

This, notwithstanding, has not wiped out the requirement for precise warm administration. Not only this, but it also eliminates the ability to do equitably appropriate the created heat and keeping away from the development of hazardous warmth collection focuses.

Some Tips for Using Proper Thermal Heat Transfer Solutions

The initial step to accomplishing thermal heat transfer solutions within the sight of high-power loads is to recognize the parts. In light of the specialized attributes of every part, the semiconductor intersection temperature TJ and warm obstruction RT.

You can conclude the first from the part datasheet, while you can characterize the second is characterized as the temperature distinction that happens along the warm way.

Specifically, RT can be limited by lessening the length of the warm way, or by expanding the warm conductivity of the material and the space of the PCB cushions. Both of these components concern the PCB format, which accordingly will be planned from the start to meet these prerequisites.

The developing race towards the scaling down of force circuits places genuine cutoff points on the expansion in cushion regions. Along these lines, to work on warm administration, the fashioner can intercede on the accompanying two variables:

- The length of the warm way on the PCB will be just about as short as could be expected;

- The materials and substrates which make up the PCB, just as any warmth sink, will have the most elevated conceivable warm conductivity.

You can meet the primary necessity by embracing unique insurances during the plan of the printed circuit board, while the second requires a cautious selection of materials to be made during the fundamental phases of the venture, for instance, the attainability study.

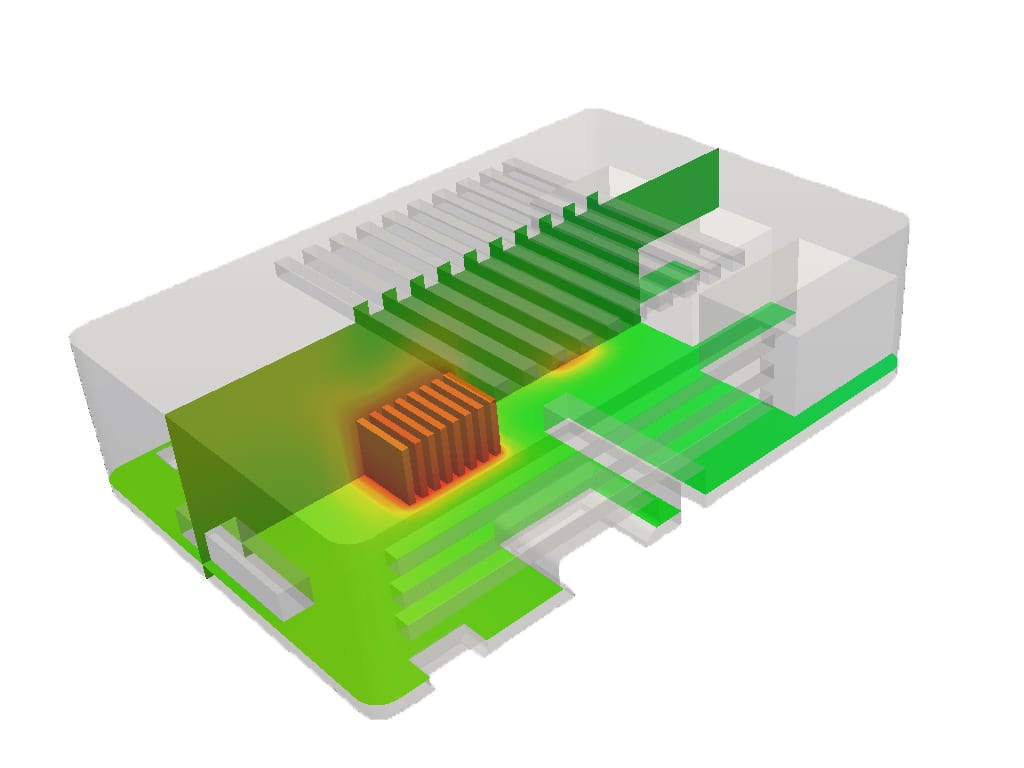

PCB Layout in Thermal Management System

The procedures accessible to the electronic planner to decrease the warm way length on the PCB are unique. Most importantly, it is prudent to expand the distance between the tracks, in this manner acquiring a more uniform dispersion of warmth on the layer, lessening the danger of making problem areas.

This arrangement, be that as it may, is frequently restricts the need (as on account of wearables) to acquire scaled-down PCB size. Notwithstanding distance, the math of the tracks is additionally a vital factor. Tracks interfacing power segments ought to be just about as short and wide as could really be expected, utilizing copper with thick statures for the tracks navigated by high flows.

The base suggested values for track width, a component of the power of the current moving through it very well may be acquired from the outlines contained in the IPC-2221 norm for PCB plan. On the off chance that you use a few tracks for a given current, there is the danger of getting debased execution or in any event, annihilating some electronic segments; if all else fails, it is consistently desirable overuse follows a more extensive width.

Another method is to embed warm vias along the warm way. Plated warm vias are more proficient, as the copper covering takes into consideration more warmth that it needs to collect.

Final Words

The thermal heat transfer solutions for PCB are undoubtedly great! That’s because they play a major role in improving the efficiency of printed circuit boards. As a result, electronic devices have become efficient too. However, do bear in mind to purchase heat transfer solutions only from reliable manufacturers and suppliers. After all, these solutions have a direct impact on the working of your products.

Need more information on this topic? Contact us now! We will gladly assist you in any way we can.