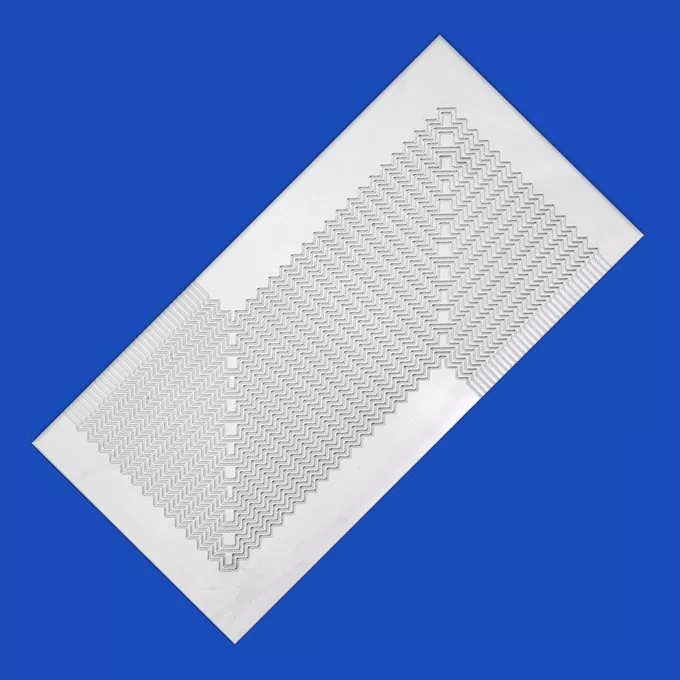

Plate heat exchanger components

The term Plate Heat Exchanger is commonly common to refer to one of the most common plate-type exchangers, the micro channel plate. A titanium micro channel plate consists of a series of thin corrugated or corrugated plates that separate the fluids.

In this type of heat exchanger, the plates have seals and come of any metal or metal alloy that is capable of being molded.

Importance of Maintenance of Plate Heat Exchangers

Plate heat exchanger maintenance is easy to carry out in two ways: the first is correction, which is required when the titanium micro channel plate has a problem and needs to be repaired.

The second is preventive, which is carried out through periodic inspections of the equipment, where qualified technicians seek to determine the failures that may occur and cause damage to the equipment.

The main advantages of maintaining Heat Exchangers are:

- Good functioning of the circuits;

- Increase in heat exchange efficiency;

- Greater safety and quality;

- Contamination prevention

- Prevention of possible failures;

- Prevents equipment breaks;

It improves the production process and introduces regular inspection.

Plate Heat Exchanger opening procedure

Firstly, the titanium micro channel plate must not open unnecessarily, as it has elastomers that are easy to damage during the opening procedure. Secondly, it is that that the gaskets be evaluated to verify their condition after opening, as they may present damage invisible to the naked eye, causing leakage after the exchanger closes.

The disassembly and assembly procedure

Disassembly steps:

- Loosening of the “X” risers.

- Clearance of all nuts to the end of the tie rods.

- Removal of straps.

- Moving plate away.

- Removal of plates.

Assembly steps:

- Checking and lubricating the lower and upper busbarsof titanium micro channel plate

- Brushing the clamping rods.

- Lubrication of the tie rods

- Placing the plates in the order of the project and later the risers.

- Tightening of the tie rods in “X”, always limited to 10[mm] per tightening

Cleaning and sanitizing heat exchangers

Thirdly, and most importantly, to ensure the normal operation of the heat exchanger, chemical cleaning recommends, in order to remove residues from the inside of the equipment that could impair its proper functioning.

Cleaning carry out with a chemical solution specially designed for this purpose, so as not to impair the operation of the titanium micro channel plate and to avoid the appearance of corrosion.

Advantages of cleaning in plate heat exchangers:

- Eliminates maintenance downtime

- Reduction of energy consumption

- Increase in service life

- Preservation of quality;

- Preventive cleaning;

- Prevents foreign bodies from getting lodged;

- Prevents deterioration and contamination

- Reduces fouling

- Increases performance

- Stability of heat exchange efficiency

- Avoids corrosion on the plates and contamination of the products;

General Manual of titanium micro channel plate

We provide a complete heat exchanger operation and maintenance manual to guide customers regarding equipment maintenance. Moreover, it recommends to comply with local safety rules to avoid injury and damage and of course to take the necessary protective measures according to the nature of your process and even the situation related to the factory.

Our plate heat exchangers specially design and manufacture to operate in different conditions, such as pressure, temperature, flow and type of fluid supplied by the customer.

Precautions must be observed

Some care is necessary, such as being careful that the temperature and pressure do not suddenly exceed the specified values, which may occur during system startup or shutdown. These precautions must observe so as not to cause serious damage to the titanium micro channel plate.

Assembly and Maintenance Course in Heat Exchangers

Check out in this course the most suitable tips and practices for the assembly and maintenance of plate heat exchangers, to ensure the best performance, economy and longer useful life of the equipment components:

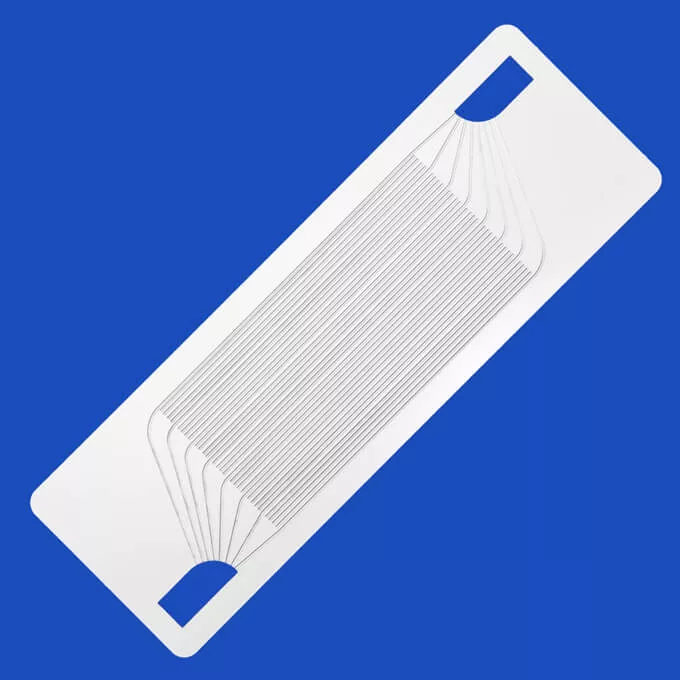

Generally, to improve heat exchange, fins place throughout the piping area. These fins cause the fluid to disperse into smaller areas, thus facilitating heat exchange. Fins, consist of cells interconnected with each other, where fluid circulates. They are made of materials with excellent thermal conductivity.

Major disadvantage in a thermodynamic system

Its use has a major disadvantage in a thermodynamic system, as it drastically reduces the pressure in relation to inlet and outlet. Most titanium micro channel plate use tubes with geometries that favor the exchange of heat, where internally, there are fins in their area.

Heat exchangers can be:

- Shell and tube heat exchanger ;

- Plate heat exchanger ;

- Circular adiabatic heat exchanger ;

- Finned plate heat exchanger;

- fluid heat exchangers;

- Waste heat recovery units;

- Dynamic scraped surface heat exchanger;

- Phase change heat exchangers.

The optimal selection of a heat exchanger is challenging

Due to the many variables involved, the optimal selection of a heat exchanger is challenging. Hand calculations are possible, but many iterations typically require. Thus, titanium micro channel plate more often selects through computer programs than by system designers, who are typically engineers, or by equipment suppliers.

Other important selection criteria

In order to select an appropriate heat exchanger, system designers (or equipment suppliers) first consider the design limitations for each type of heat exchanger. While cost is often the first criterion assessed, there are several other important selection criteria that include:

- High and low pressure limit;

- Thermal performance;

- Temperature ranges;

- The set of products (liquid/liquid, liquids with particulates or high solids content);

- Pressure drop along the titanium micro channel plate;

- Fluid flow capacity;

- Cleaning, maintenance and repair features;

- Materials required for construction;

- Capacity and ease of future expansion.

Different types of heat exchangers

Choosing the right heat exchanger requires some knowledge of different types of heat exchangers, as well as the environment in which the unit will operate. Typically, in the manufacturing industry, several different types of heat exchangers are common for only one process or system to obtain the final product.

For example, a kettle heat exchanger for preheating, a twin tube heat exchanger for the carrier fluid, and a plate and frame heat exchanger for cooling.

In conclusion, with sufficient knowledge of titanium micro channel plate types and operating requirements, an appropriate selection comes to optimize the process.