Everything You Need to Know About Application of Heat Exchanger Technology

Want to know the application of heat exchanger technology? Well, you have landed at the right place. In this guide, we will tell you everything you need to know about heat exchanger technology and its benefits. So, make sure you stick right to the end!

Heat Exchanger Technology – Introduction

Simply put, the heat exchanger technology comprises a device that moves heat starting with one source then onto the next. An incredible illustration of a warmth exchanger is a pressure-driven oil cooler. It works by eliminating heat from oil with the assistance of cold water or air.

Other than that, there are pool heat exchangers accessible in the market too. It utilizes high temp water from a sunlight-based warmed water circuit or heated water from the kettle to warm the water in the pool. Warmth is moved to the water with the assistance of conduction and the exchanger materials. These exchanger materials separate the medium that you use in warming up the fluid.

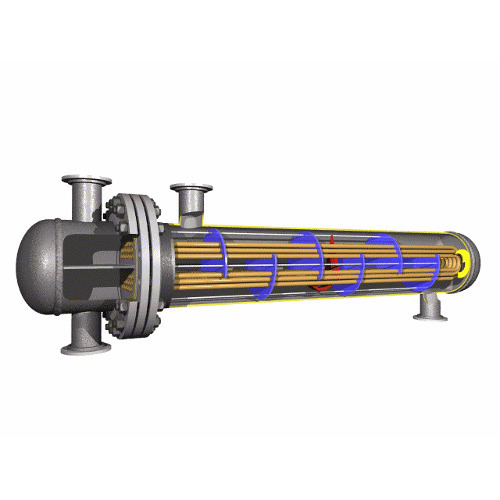

Another normal kind of warmth exchanger is the shell and cylinder heat exchanger. These gadgets go the liquids through the cylinder where the air-cooled heat exchanger passes the cool air through the center of blades to chill off the fluid.

Working Of The Heat Exchanger Technology

The working of the heat exchanger technology is quite simple once you get hold of it. The technology comprises a few basic steps. Let’s check out these steps below.

- The first thing that the originators do is assemble the casings. What you can be sure of is that the edge comprises pressing factor plates also. Both the top and the lower part of the casing comprise associations and bars. In addition, the fashioners balance the last plate in the bar first.

- The second step includes situating the plates on an edge. In any case, you additionally need to comprehend that you need to compare the plates precisely to their detail.

- In the third step, the makers fix the bolts and fit them in a plate pack. Moreover, they likewise fix the screws with a spanner or whatever other appropriate instruments that you like.

- It then, at that point stacked with bolts between the plates. The upper passing on the bar keeps up with the channel and pressing element plate. They are then fixed in a situation by a lower regulating bar on the help divide. This course of action is not at all difficult to edit or change (by killing or adding plates).

Usage Of Heat Exchanger Technology

Different manufacturing companies use heat exchanger technology in their business to avail the many benefits that they offer. Let’s check out some of the applications below.

- Food and Drink Industry

- Oil and Gas Processing

- Chemical and Petrochemicals

- Paper and Board

- Prime Movers

- Textiles and Fabric Care

- District Heating/Cooling

- Air Compressors

- Refrigeration

- Mechanical Vapor Recompression

- Cryogenics

Advantages

The heat exchanger technology offers many benefits to both the companies and the users these days. That’s why more and more companies are adopting this technology. Let’s check out some of its benefits below.

1. Low Impact on Environment

The heat exchanger technology offers a low environmental impact during the process. That is on the grounds that these machines run consistently to guarantee that control boards that are of incredibly high force don't warm up. This is because of the way that these machines don't need confounded outer hardware to run appropriately. Since they use fundamentally less energy and produce no contamination when contrasted with the other regular cooling strategies, they leave a lower sway on the climate also.

2. Saves Energy

Sterilization relies upon the warmth exchanger's ability to recover heat from milk. For decontamination, milk should be taken care of at 4°C to hinder microbial turn of events. During decontamination, milk is warmed to a temperature of 72 °C for no under 15 seconds to kill microorganisms and a while later chilled back to 4 °C to stop the cycle and secure the milk. The warmth of the cleaned milk is used to warm the infection milk. The moving toward infection milk is preheated by the dynamic hot milk, which is meanwhile pre-cooled. This trade efficiency saves warming and refrigeration energy.

3. Fewer Footprints

The heat exchanger technology offers a smaller footprint as compared to other technologies that the companies use. The advancement of modern technology makes these devices more powerful but smaller and versatile as well. As a result of the shrinking space, the footprint becomes smaller. This is what makes these devices extremely efficient to use.

4. Less Operating Cost

Another incredible advantage of the heat exchanger technology is that it needs the least working expense to run. That is on the grounds that they don't utilize any muddled outer hardware. Also, the machines take out most of the tainting. These gadgets additionally don't separate effectively and can keep going for a more extended time frame when contrasted with the other cooling units. That is the reason the need to supplant them lessens.

5. Offers Consistent Temperature

Heat exchangers play an important part in making predictable temperatures for the food and drink industry too. What's more, they help in cleaning the liquids from the framework parts too. This is the thing that settles on it the top decision of individuals.

Final Words

We hope this guide answered all your queries related to heat exchanger technology. It is an extremely effective technique that companies use nowadays for transferring heat from one place to another. The hydraulic cooler is a great example of this technology that works by removing heat with the help of the air or cold water from the oil. In addition to this, there are many types of heat exchangers out there as well. You can choose the one that best fits your needs.

Want more information? Contact us now!