Vacuum diffusion bonding technology with semi-automatic equipment with constant wire feed allows you to increase labor productivity, creating strong seams even on thin sheet work pieces. It can be common to weld significant amounts of metal onto body parts or join large metal structures.

The main consumable is the wire that forms the seam. On online stores, you can buy diffusion bonding wire for a semiautomatic device in various designs and diameters.

Advantages of semi-automatic diffusion

Among the advantages of semi-automatic diffusion bonding, there is one significant drawback - it is necessary to deliver a cylinder with an inert gas to the workplace. Its weight is 83 kg, which significantly reduces the operator's mobility.

Moreover, a vacuum diffusion bonding technology has been developed that uses flux cored wire for gas-free diffusion bonding. This significantly increases mobility and makes it possible to work in hard-to-reach places.

Material features of vacuum diffusion bonding technology

Firstly, to form a high-quality weld, the working area should be protected from oxygen until the metal cools down. The process is carried out in various ways - by combustion of a flux or by using an inert gas. It is sometimes difficult to transport a bulky cylinder to the job site, and diffusion bonding with coated electrodes does not provide high productivity.

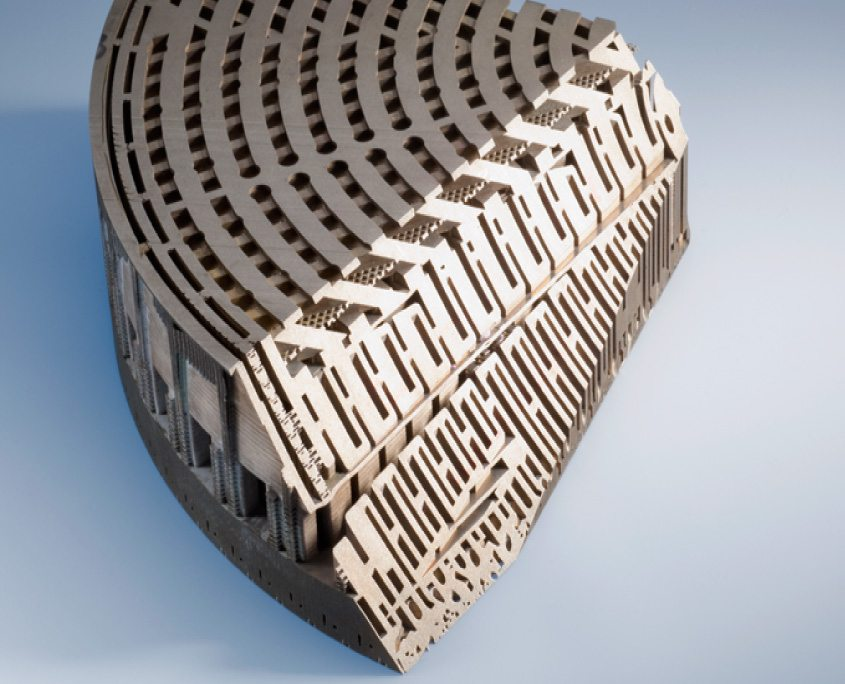

Then, flux-cored wire vacuum diffusion bonding technology solves both problems. This consumable comes in the form of a hollow thin-walled tube filled with a mixture of fluxes. As the current flows, the arc stops and the consumable begins to melt.

Moreover, flux cored wire is equipped with one or more stiffening ribs, which protect the material from accidental wrinkling.

Scope of vacuum diffusion bonding technology

Diffusion bonding with flux cored wire is very much in demand when working in inaccessible places (in tunnels, underground or at a height). In this way, metal structures quickly weld, but the material is not suitable for repairing pressure vessels.

Further, vacuum diffusion bonding technology without gas is in great demand due to the large selection of diameters (0.8 - 2.4 mm), which allows you to work with work pieces with a thickness of 1.2 to 10 mm. The method is applicable to carbon steel, galvanized steel and stainless steel

Advantages and disadvantages of vacuum diffusion bonding technology

As with any technology, diffusion bonding without shielding gas has its own characteristics.

Advantages:

- Firstly, no need to carry a gas cylinder with you

- Secondly, the ability to carry out work in hard-to-reach areas

- Thirdly, high performance compared to the use of coated electrodes

- Fourthly, the arc is not sensitive to wind gusts

Disadvantages:

- At first, Insufficiently high quality of the seam

- At second, high cost of consumables

Flux-cored wire vacuum diffusion bonding technology technique

This type of vacuum diffusion bonding technology has a number of features:

- It is necessary to set the polarity to the right

- Do not over tighten the pinch roller to avoid damaging the wire

- Remove the tip before pulling the wire

Further, the diffusion bonding current is one of the most important diffusion bonding parameters. In the previous article, I talked about the fact that in most cases, the real diffusion bonding current does not correspond to the values indicated on the diffusion bonding machine. And now I will tell you how to be in such a situation.

How to handle vacuum diffusion bonding?

Actually, this problem is easy to solve with the help of "hardware", and you can - at the expense of your own qualifications. To solve this problem with the help of "iron", you need to embed an ammeter into the vacuum diffusion bonding current circuit.

“On this topic, I can propose to include in the circuit: output“ + ”of the inverter - electrode holder – work piece to be welded - mass, additional digital or analog ammeter with a shunt of 200-300 A. It is desirable, of course that the shunt and the device fit into the welder's body.

However, some craftsmen make the meter a separate unit and use it as needed. The benefits are clear! You will see the real current in the circuit: holder-part-mass, any unreliable contact in this circuit will make this current noticeably less.

What will be the result of lack of voltage in vacuum diffusion bonding technology?

Lack of mains voltage will also show a decrease in vacuum diffusion bonding technology current in any machines, except for some professional expensive and reliable firms. The selection of the diffusion bonding current in this case will have to be carried out empirically, but not "blindly", but by looking at the ammeter of the real current.

That was the message, and I can only add that the only problem in this case is that during diffusion bonding you will need to monitor the progress of diffusion bonding.

Furthermore, to find out the values of the ammeter, you will need to come up with something - for example, contact an assistant. Otherwise, this method really allows you to find out the real diffusion bonding current.

How an experienced welder selects the current of vacuum diffusion bonding technology?

As I said earlier, the problem of false information about the current of vacuum diffusion bonding technology can also be solved through your qualifications in the field of electric diffusion bonding. This means that it is possible and necessary to learn how to determine and select the optimal diffusion bonding current.

Physical and chemical process of vacuum diffusion bonding technology

The fact is that the physical and chemical processes occurring during diffusion bonding look a certain way and generate certain sounds. You can observe and analyze the intensity of the arc, the area of melting, and the fluidity and solidification rate of the liquid metal.

What are the signs of an overestimated diffusion?

Signs of an overestimated diffusion bonding current are:

- Strong splashing of liquid metal

- Little convexity of the weld or its complete absence (up to the depression)

- Rapid combustion of the electrode

- Strong hiss and other signs

How to select correct diffusion bonding?

The correct and optimal diffusion bonding process looks and sounds in a certain way. And knowing this look and sound, you can experimentally select the correct current OF vacuum diffusion bonding technology without any indicators.

They say about the underestimated diffusion bonding current:

- Difficult ignition of the diffusion bonding arc

- Unstable arc burning

- Fast solidification of metal

- Small weld pool

- Excessive bulge of the weld other signs

Furthermore, the melting process of the electrode coating, the bulge of the resulting weld, the ease of initiation and stability of the diffusion bonding arc and other phenomena. The sound accompaniment of vacuum diffusion bonding technology, first of all, includes hiss and crackling.