What is water to the air heat exchanger?

Water to the air heat exchanger is a device common to perform heat exchange between heat carriers. These heat carriers can be separated from each other by plates (or plates) to prevent mixing or direct contact between the heat carriers.

In engineering, this equipment plays an important role in the process of steam generation, condensing, and evaporating devices. Example: In a car, a heat exchanger is common to convert the heat of the engine to the radiator to the outside air and cool the engine.

Applications of water to the air heat exchanger

Water to the air heat exchanger that transports heat from hot water to the air is known as a water-air heat exchanger. For domestic air conditioning, heating, and dehumidification, a heat to water exchanger is often common in condominiums and apartment buildings.

At present, water to the air heat exchangers is widely applied in our life such as space heating equipment, air conditioners, air conditioners, energy production plants, chemical plants, houses, etc.

Classification of heat exchanger

Heat exchangers today are very diverse in types and often depend on the technology of their manufacture. However, in terms of working principles, we can classify them into three main types as follows:

- Baffle type heat exchanger

- Heat exchanger type water to the air heat exchanger

- Mixed type heat exchanger.

Some basic points about heat exchanger

Each form of equipment has its advantages and disadvantages, so depending on the production technology; you will choose one type or another. According to Remen's observations, on the Vietnamese market today, baffle-type heat exchangers are most commonly common.

Inside this device, heat carriers are moving inside spaces separated from each other by partitions that are heat transfer surfaces. For example, a fluid moving inside the tube and a fluid outside the tube will transfer heat to each other through the surface of the pipe wall.

Flow arrangement in the heat exchanger

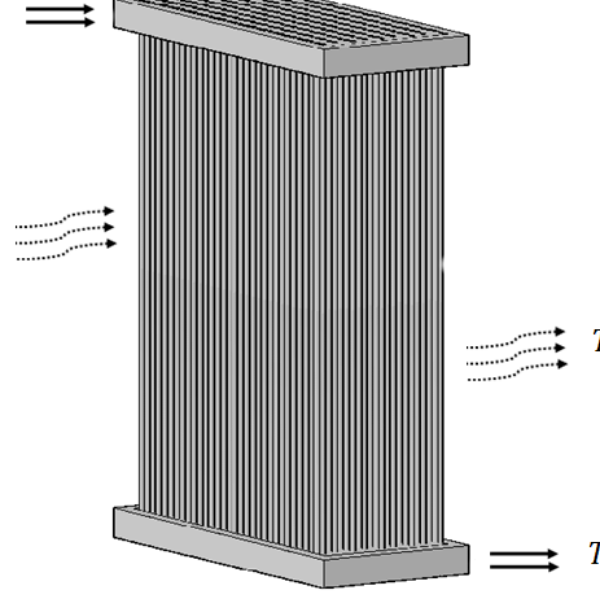

Based on the traffic arrangement, equipment is divided into two types, including Cross-flow water to the air heat exchangers: Here, the fluids will pass roughly perpendicular to each other through an exchange.

Reverse heat exchanger: that is, the liquid flow will enter the device from opposite ends. According to research and practical application, this type of device offers the highest efficiency; it can convert the maximum heat from the heat transfer fluid.

Enhancing the efficiency of heat exchanger

To ensure maximum efficiency, most waters to the air heat exchangers are designed to maximize the surface area of the plates between the two fluids. Besides, it also minimizes the liquid flow obstruction through the heat exchanger.

Today, the heat exchanger is an indispensable part of life; it appears in many everyday devices we see and use or in buildings, commercial centers, etc. Most of the device's water to the air heat exchangers is now imported from well-known brands in the world.

Usage of water to the air heat exchanger

Heat exchangers are widely common in factories, factories, and workshops. Water to the air heat exchanger is essentially a device that performs heat exchange between heat carriers as its name implies.

For example, you have a substance in liquid form, commonly common in water, chemicals, solutions, or vapor (gas) form, needs to be heated or reduced in temperature to meet production requirements, the water to the air heat exchanger is an extremely good solution.

Types of heat exchanger

In principle, all heat exchangers usually have the same purpose, using either heat reduction or heating. But depending on the environment and production technology, the pyrolysis exchanger is divided into many different types, specifically common heat exchangers such as:

- Firstly, baffle heat exchanger.

- Secondly, heat exchanger heat exchanger.

- Finally, mixed heat exchanger.

What is a heat exchanger?

In terms of technical aspects of heat exchangers, each type has different strengths and weaknesses. Therefore, companies, and enterprises, depending on the production technology, choose one type or another.

The baffle-type heat exchanger is very popular and widely common today. In this type of water to the air heat exchanger, the heat carriers move continuously in spaces separated by a baffle which is the heat transfer surface of the heat exchanger.

Plate heat exchanger

Plate heat exchanger (PHE for short) is one of the cooling equipment in the industry. Water to gas heat exchangers composes of many thin metal plates sealed by rubber gaskets to create a barrier between hot and cold fluids.

These two hot and cold fluids will flow alternately between the plates, called plate heat exchangers.

Plate heat exchangers

Because water to the gas heat exchanger plate has a large surface area, it creates a large heat exchange surface between the media. Comparing beam-tube with any heat exchanger it has a better heat efficiency, and its cleaning and maintenance are also easy.

A heat exchanger is a device common to transfer heat between two or more heat carriers. In applications, heat exchangers can be common for heating, cooling, evaporating, and condensing. The heat exchanger is common for heat recovery, pasteurization, sterilization, and control.

Types of water to the gas heat exchanger

Currently, plate water to the gas heat exchangers has the following basic types:

- Firstly,gasket type

- Secondly, sealed plate type

- Also, semi-welded plate type

- Wide gap plate type

- Finally, type of tubular plate.

Diversity in the water to the gas heat exchanger

Due to the above diversity, water to the air heat exchangers can be classified based on application, the quantity of heat carrier, heat exchanger surface shape, device structure, flow structure.

- Shell & tube heat exchanger

The device consists of a bundle of tubes inside through which a liquid needs to be heated or cooled. This device is commonly common for applications requiring high working pressure and temperature. The design of this type of heat exchanger depends on several factors:

- Pipe size: Using small pipes will reduce costs, compact equipment,

- Conversely, small pipes will be difficult to clean, dirty (fouling factor)

- Pipe thickness: Deciding on heat transfer coefficient, abrasion, spare parts availability

- Pipe length, the distance between pipes, baffles

Classification of shell and tube heat exchanger

This device can be classified as below:

- Double pipe type water to the air heat exchanger

- Moreover parallel flow to the tube heat exchanger

- Cross flow to the tube heat exchanger

- Also, spiral tube heat exchanger

- Plate type heat exchanger

The device composes of many thin plate water to the gas heat exchangers, with a very large heat exchange area. The device offers large heat exchanger efficiency and small size compared to the beam tube type heat exchanger.

Rubber gasket materials and welding techniques today make plate heat exchangers widely common.

Classification of plate type heat exchanger

- Firstly, plate heat exchangers use gaskets to seal heat transfer plates.

- Secondly, welded plate water to the gas heat exchanger

- Brazed heat exchanger

- Moreover, spiral heat exchanger

- Finally, plate coil heat exchanger

- Gas-air heat exchanger

The gas flows through parallel plate water to the gas heat exchangers. The equipment is mainly common in the furnace system. Its functions are given below,

- Firstly, air Preheater

- Secondly, waste Heat Recovery

- Moreover, air Heater

- Hot Air Generator

- Acts as a recuperate

- Also the temperature the maximum design achieves 1000 ℃.