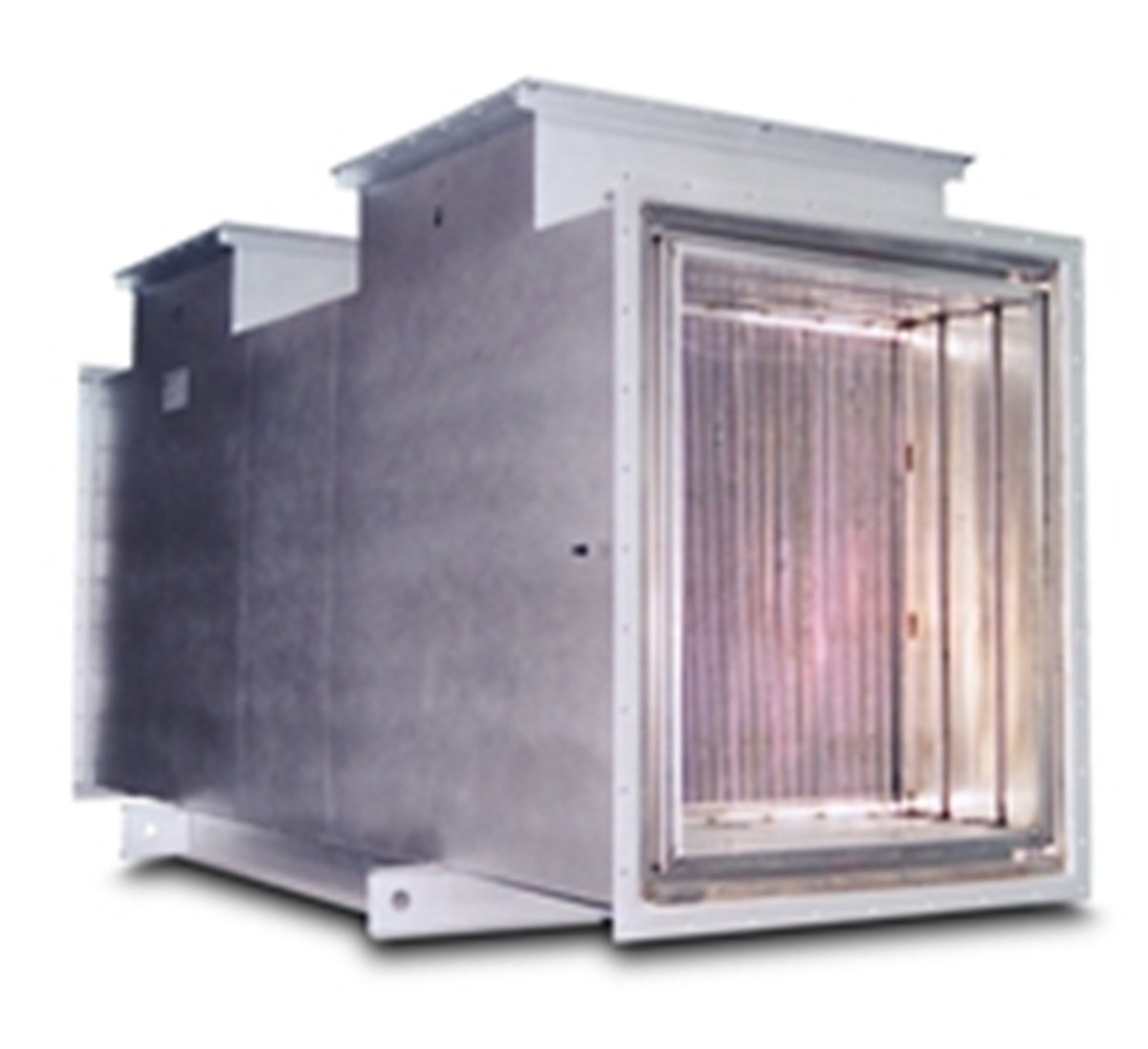

Depending on the task at hand, welded heat exchangers can perform one or several functions, respectively, be executed in the form of a mono block or a larger unit. A block heating station of a mobile type makes it possible to install equipment quickly.

Application areas of welded heat exchangers

The block heating point is not limited to one area of application. It ensures the efficient operation of various systems, including their options such as:

- Firstly, uninterrupted supply of energy carriers

- Secondly, hot water supply

- Apart from this; heat supply to ventilation, air conditioning and heating systems

- Additionally, various technological tasks in industrial conditions

- Moreover, heating of viscous substances

- Lastly, washing of technological containers

Varieties of block heating points

Equipment’s of welded heat exchangers are mass-produced and can include almost any combination of functional modules. There are several subtypes of BTP:

- Also, connection of the heating network to a common main (dependent type)

- Finally, using plate heat exchanger for independent connection of heating network to common main

Areas of use of block heat points

- First, it’s common in renovation of units and modernization of technically outdated heat points

- Second, thermal carriers are being modernized for uninterrupted functioning

- The need to provide hot water in commercial, administrative, and residential buildings

- Finally, in design and installation of heating systems in separate boilers and boiler rooms

How does an individual heating station work?

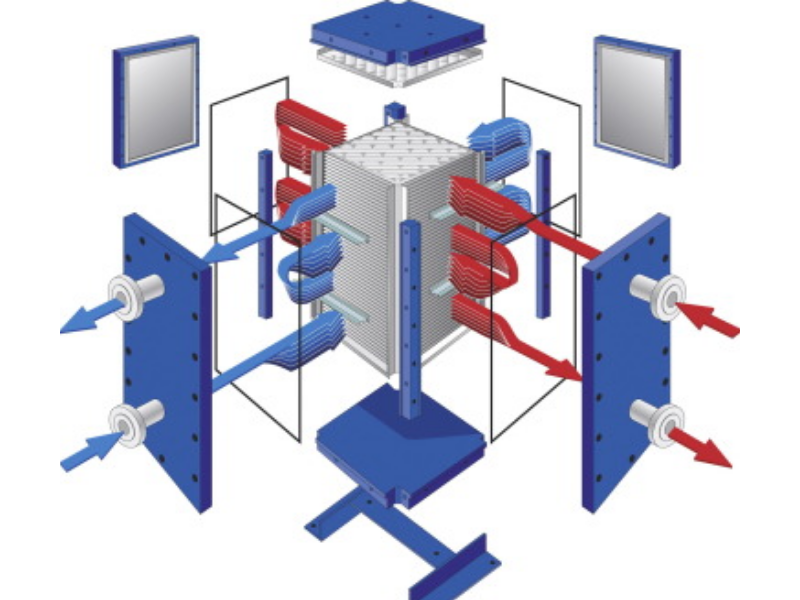

ITP is a rather complex system for welded heat exchangers that consists of several types of technological equipment. The task of an autonomous heating point is to transfer the thermal energy necessary for heating the premises to consumers, supplying it from the main line.

An individual heating station automatically distributes heat between the nodes connected to it: a hot water supply system, ventilation and heating.

The purpose of creating and installing such systems is to save energy resources; the reason for such savings is temperature control depending on current weather conditions. The temperature sensor reads the air temperature and adjusts the network temperature to it.

How does the ITP work with Welded heat exchangers?

The first and one of the fundamental shortcomings of the resources that come from the highway to consumers is the discrepancy between their current technological standards of welded heat exchangers. This applies to both heating water and conditionally drinking water common for hot water supply.

The task of the ITP is to supply the end consumer with good quality water, and this requires modern communications. ITPs can function both for the purpose of providing one premises, and for servicing multi-story buildings - both residential and commercial or administrative.

Nodes in ITP

The list of main nodes includes:

- First, control panel (one or more)

- Second, regulating and shut-off valves

- In addition; heat exchangers (plate type)

- Furthermore, pumping station

- Expansion tanks

- More importantly, controllers and meters of operating parameters

Working mechanism of welded heat exchangers

Heat transfer in welded heat exchangers to the hot water supply and heating systems occurs due to the operation of heat exchangers, which transport it from the centralized unit to the consumer. At the same time, water does not come to the consumer and is not common by him, but only acts as a heat carrier.

Further, the pumps perform their function. They balance the pressure difference (paired), and the circulating one ensures movement and sufficient head. The shields and controllers automatically adjust the operating parameters.

Its degree is planned even during the design of the ITP. Its maintenance due to the manufacturability of the entire system is minimal. More often, it includes a routine inspection, regular cleaning of heat exchangers and replacement of consumables (filters).

What processes carried out by an individual heating station

Following are some of the processes come in welded heat exchangers

- Accounting for consumed thermal energy

- Water preparation for heating and hot water supply systems

- Conversion of coolant parameters

- Protection against emergency situations in automatic mode

- Filling and control of the coolant level in heat supply systems

- Use of condensate with its preliminary collection

Welded heat exchangers operational mode

The mode of operation of the ITP depends on which temperature graphs implement come in each specific line. An inlet temperature exceeding 95 degrees is subject to adjustment - in this case, the valves open the flow of cold water, which brings the coolant to the correct parameters.

In different centralized lines, there may be different temperature scales in the supply and return systems, however, the outlet temperature will always be 70 degrees. At the entrance, it can range from 90-95 degrees to 150 degrees.

How to use welded heat exchangers Components correctly

For the correct functioning of a substation of welded heat exchangers, a set of the main elements of the system is required. These include:

- Exit node to the reverse part of the highway

- Input type node

- Flow metering devices

- Equipment for hot water supply, heating, and ventilation systems

- Pressure control device between heat recovery and heat utilization systems

- Electrical appliances for ventilation and heating

Working scheme of welded heat exchangers:

The design of each scheme is individual and depends on both the design and the task at hand. The heating system can be one- and two-stage, while the first option is more often common in residential buildings since the water in this case will be heated from the coolant of the line itself.

Project creation and commissioning

During the drawing up of the scheme, the creation of the project and, necessarily, when the welded heat exchangers is put into operation, technological and sanitary standards we must observe. In other words, the equipment of a substation must come by the installation of an automatic control device, control and measurement devices, and installation fittings. In general, the entire ITP should:

- Maintain the fullness of the heating system

- Control the amount of consumed heat carrier

- Consider the consumed heat power, condensate, and heat carrier losses

- Regulate, control and measure temperature and pressure

- Disconnect equipment in case of emergency

Applications of welded heat exchangers

The use of pressure gauges and mud filters, as well as welded heat exchangers with maximum operating parameters, mesh filters prescribe. Installation above residential premises is not good to install. ITP can be common not only for heating, hot water supply and ventilation.

Such assemblies are an excellent method for providing thermal parameters during technological production processes. For instance, this application can be common in flushing various containers, heating liquids and pasteurization.