Heat exchangers help to dissipate heat where there is a temperature difference

Heat exchangers, as the process, Energy flow, itself, in physics follows the equalization principle. Hence, by principle, the energy flow goes into the system and runs into the system until it reaches a uniform state. This principle thereby is better famous as temperature difference. Where the heat dissipates until it reaches the equilibrium state. The heat exchanger that carries the plate uses the phenomenon where heat cuts through the surface. In this process, the phenomenon separates the hot heat medium into the cold medium. Eventually, making the process of heating and cooling fluid and gases an easy task with a minimal amount of energy required to do so. Read more about heat exchange here

Theory Behind Heat Transfer in Heat Exchanger

The theory of heat transfer, the equalization principle, as we have discussed above happens for several reasons and factors. Amongst these some profound of them are:

- The difference in heat intensity makes the foremost reason for heat transfer theory. This law states that the heat flow of the fluids and gases happens only when there is a hot medium and cold medium at the same time. In these conditions, heat always transfers from hot to cold medium.

- Apart from the presence of a hot and cold medium for the heat to transfer, there is a compulsion of the presence of temperature difference between the different mediums. It is because whenever there is a difference in the temperature of the medium, the heat will consequently flow from one medium to another.

- Last but not least is the process where the law of conservation of heat comes into play. By this it means that whenever there is a flow of heat involves in the process, the total amount of the heat remains the same. This is better famous as the Law of conservation of heat. Therefore, the heat loss from the hot medium eventually will be equal to the heat gained by the cold medium.

What is the Heat Exchanger?

A heat exchanger as the name suggests is the instrument or device that helps in exchanging or transferring heat from one medium to another. By this use, the heat exchanger hence is available in different models or types. Generally, there are only two types of heat exchangers available. These are:

- Direct Heat Exchanger

- Indirect Heat Exchanger

A direct Heat Exchanger is something, as the name suggests, where there is direct contact involved. By this it means that there is a direct contact between both mediums is involved is better famous as a direct heat exchanger. The best example of this exchanger is the cooling tower. It is the type of cooling tower where water gets to cool down by contracting directly with the air.

An indirect Heat Exchanger by name is the process or instrument that performs the transfer and exchange of heat by using a different or divided medium.

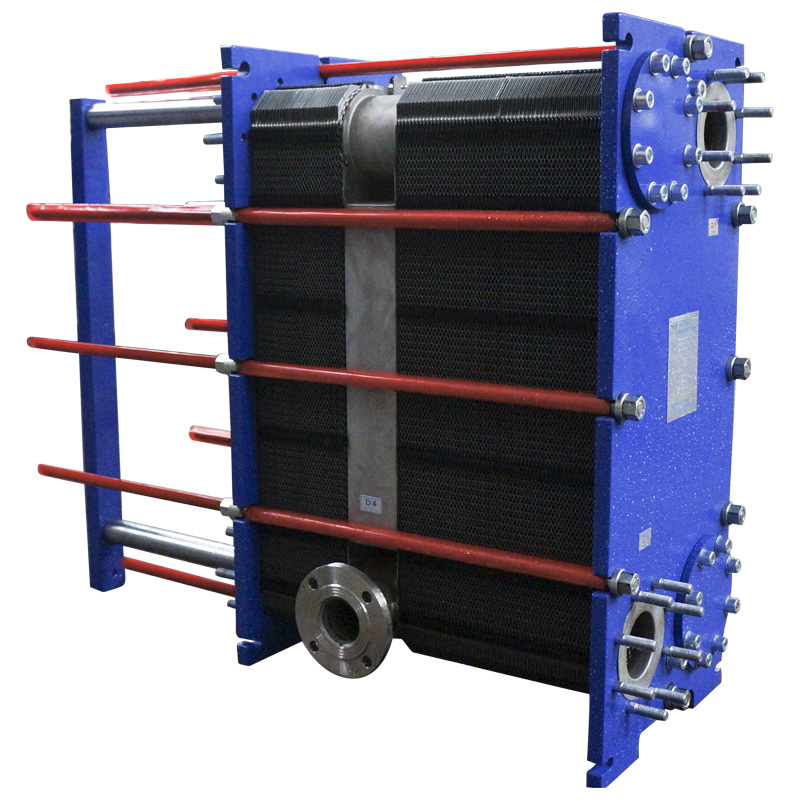

Design of A Plate Heat Exchanger

The modern heat exchanger carries plates. This is the reason hence; it is referred to as a plate heat exchanger. The abbreviation of this device is PHE. As per the name, it carries several plates. There are two types of plates in its design. One is the fixed plate. Whilst other one is the low-pressure loose plate. However, both of these heat transfer plates carry their separate gaskets arrangements. It thus makes them two separate channel flow systems.

The presence of the gasket arrangement in each channel, therefore, allows the heat to flow in single channels. This thereby makes them primary and secondary media. In addition to this, there is no chance of mixing between these two mediums using gasket management. The presence of plates thereby allows turbulence in the fluids. This turbulence eventually helps in providing effective heat co-efficient.

The StollPCHE holds the best record for creating heat exchanger devices for many industries and several applications. These devices thereby cover the process of heating, cooling, evaporation, condensation, and heat recovery processes.

The PHE is the most sustainable heat transfer solution for simple and complex applications.

How (GPHE) Gasketed Plate Heat Exchanger Works?

The Gasketed Plate heat exchanger is the perfect solution for the optimization of heat transfer. The plates in the system thereby provide the best solution of heat transfer from one liquid or gas solution to another. The material for the gaskets used in the plates is elastomeric. hence, sealing the channels and thereby directing them towards alternate channels. This plate pack happens between the frame and pressure plates. To join the plate pack, we use the pairs of bolts between the two plates. Also, to support the channels and pressure plates there is an upper carrying bar. Eventually, the channel and pressure plate are in a fixed position using a lower guiding bar. This bar attaches itself to the support channel. Therefore, cleaning and removing the plates eventually becomes easier making it a convenient design.

Advantages Of Using the Plate Heat Exchangers

There are many advantages of using the Plate heat exchanger. Major benefits are:

- The foremost advantage of using the heat exchangers is the precision of the heat transfer rate. There is also an improvement in the temperature approach. Furthermore, the flow of counter-current appears to be real-time. Last but not least is the less amount of volume hold up in the system. There are the chances of 80% to 90% of less volume hold up.

- The cost of capital is low and also there is a low capital investment required for the installation. Also, owing to its maintenance, the PHE requires a very low or minimal maintenance cost. Lastly, the operating cost of the system also appears to be less than one can expect.

- The PHE is a very durable and reliable product. It eventually makes it free from any possible fouling, wears, stress and corrosion.

- There is a greater chance of expanding the capacity of the heat exchanger.

- The process also appears to be much responsible than ever. With PHE there are fewer chances of energy consumption hence making it to be energy efficient. With less consumption, there are fewer chances of side effects and thereby reducing the need for cleaning.

For more information, guidelines and services, feel free to visit and contact our customer support help here