If you pour hot water into cold water, you get warm water. This comes on a well-known physical principle. The zigzag micro channel perforated plate also makes use of this.

However, its structure, consisting of several individual plates lying close together, ensures that the two media do not mix with each other. In the following you will learn more about the application, functionality and costs.

The plate perforated plate is a special type of perforated plate

- It transfers the thermal energy of a warm medium to a cold one, thereby ensuring temperature equalization between the two.

- The media, usually water or gas, remain in separate circuits and do not mix.

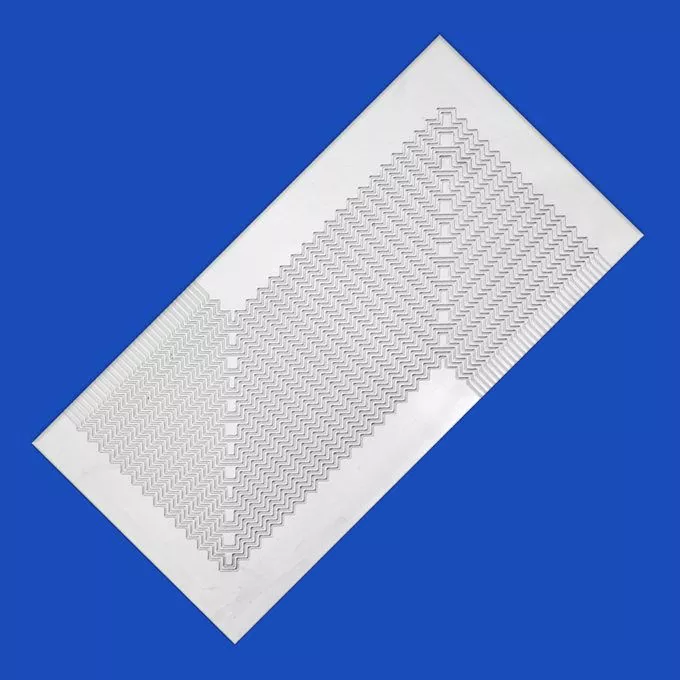

- This perforated plate consists of a multi-part plate package. One end zigzag micro channel perforated plateat the beginning and one at the end, and several channel plates in the middle.

- The number of plates can vary depending on the performance of the device. There are also differences in the type of plate connection (usually soldered), the flow direction of the media streams, the material and the size.

A plate perforated plate is a device that is good to use, for example, in refrigeration and air conditioning technology or heating construction. It transfers the heat from one medium to a colder, different medium.

What is a plate perforated plate?

This zigzag micro channel perforated plate consists of several plates. These are at a small distance from each other. In between, liquid or gaseous media flow separately from each other. During this process, thermal energy is transferred from the warm to the cold medium.

Where is plate perforated plates good to use?

Plate perforated plates are good to use wherever a liquid medium needs to be heated or cooled. This function is important for all technical systems, especially in the following areas:

- Industrial plants

- Heating technology

- Refrigeration and air conditioning technology

- Offshore technology

Construction

This type of zigzag micro channel perforated plate comes above all by its special design. It consists of several individual plates that perform the function of indirect heat transfer.

How a plate is perforated plate constructed?

In general, a plate perforated plate consists of several corrugated, profiled plates that connect to one another. This then results in a so-called plate pack.

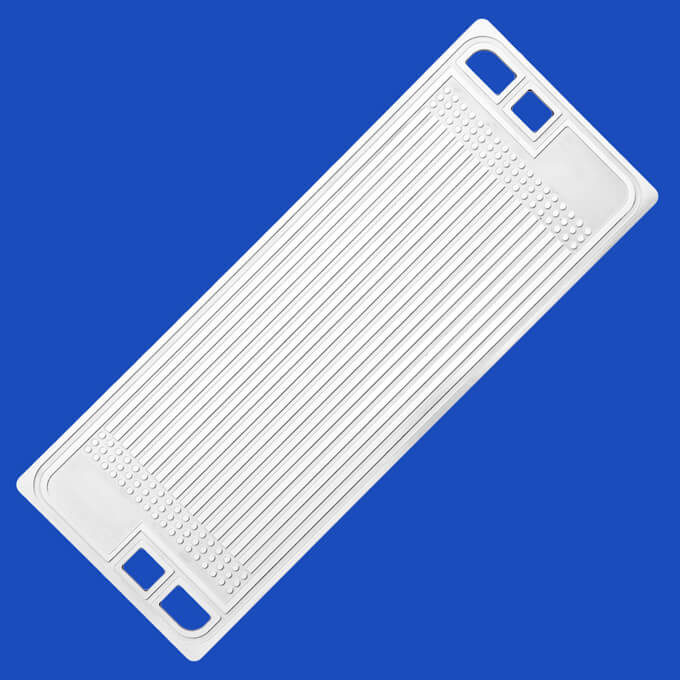

At each end, this pack is bounded by an end plate. The front one calls the connection plate. The connections for the pipelines locate on it. Its counterpart on the back is the pressure plate.

Each end of zigzag micro channel perforated plate, i.e. both the connection and the pressure plate, comes up of several parts. These elements ensure an optimal seal and thus a high transmission performance.

Herringbone or chevron patterns are also not uncommon

Between the two end plates are the heat-transferring individual plates, the so-called channel plates. These do not have a smooth surface, but have wavy indentations. Small air currents then develop in these small gaps.

This makes heat transfer much more efficient compared to a smooth surface. In addition, each plate has a channel on the inside through which the respective medium can flow.

The number, size, material and embossing of the individual zigzag micro channel perforated plate can differ from device to device. The decisive factor here is the type of application, the required heat output and the medium to be transported.

Are there differences in structure?

The plate connection can be different. There are brazed, welded or screwed models.

Soldered: The individual plates solder together at the contact points. An exchange of defective parts is not possible. The entire device must replace here.

Bolted: Turnbuckles hold the channel plates together. This rather loose construction allows the perforated plate to be expanded later or defective plates to be replaced.

Laser-welded: Always two channel zigzag micro channel perforated plate welds together and form a tight cassette. These are then held together by screws. The individual cassettes can be exchanged.

What size are plate perforated plates?

A standard household device, which is located in your heating system, for example, has a handy size. It is about 10 centimeters wide, 20 centimeters long. The depth of the perforated plate depends on how many channel plates are good to use in it. The more there are, the greater the performance that can be achieved.

The situation is different with plate perforated plates, which are good to use in large industrial plants. These can stand on their own and be up to two meters tall.

Have the design of your perforated plate calculated by a specialist company. Then it is guaranteed that the equipment fits exactly to your respective system from the heating or air conditioning technology. The device will only work efficiently if it is properly sized.

Micro channel perforated plate: functionality

The structure of the heat transfer device is decisive for its functioning. One medium can heat another without materially mixing with it.

How a zigzag micro channel does perforated plate work?

Each plate perforated plate has four connections, two for the heat-emitting medium and two for the heat-absorbing one. Both flow through the perforated plate without mixing and practically exchange the heat in it. The direction of flow is decisive for how high the amount of energy is that transfers to the colder medium. It can run parallel or diagonally:

Counterflow: The two media flow in opposite directions towards and past each other.

Direct Current: The direction of flow of the two streams is the same.

Cross flow: The two currents cross each other.

By far the highest heat transfer occurs in counterflow models. These are the most efficient and are therefore the most frequently good to use.

Summary: zigzag micro channel perforated plate

Regardless of the direction of flow, every zigzag micro channel perforated plate perforated plate works in the same way. The two streams flow into the perforated plate via the connections at significantly different temperatures: one is warm, the other cold. Immediately after entering the apparatus, they hit the plates and flow into the respective channels.